Brand Name: OMS

Model Number: TBM30/35/40

Place of Origin: China

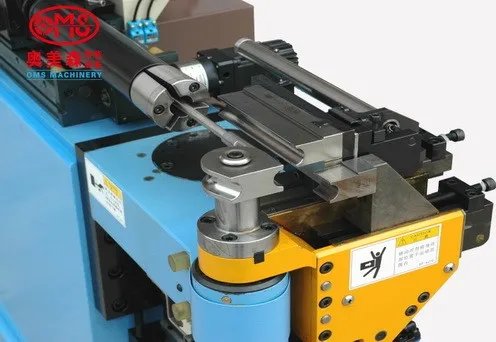

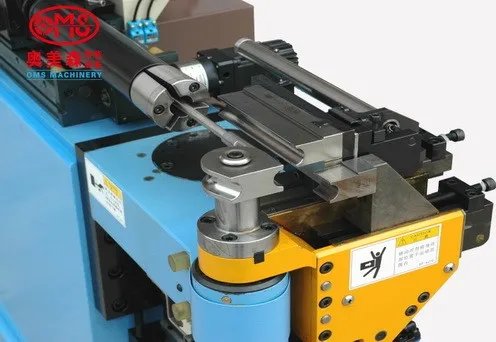

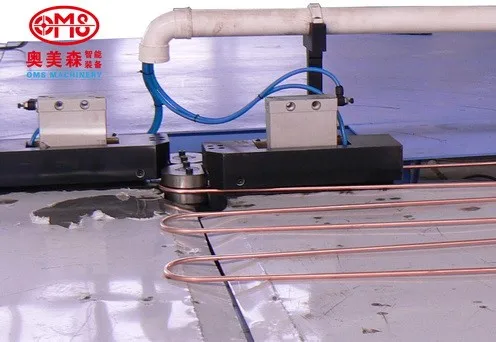

Pipe Bending machine

Use: 3D molding of various tube. Widely applied to air-condition, engine and furniture

Features:

1) Three axes CNC, hydraulic clamping, integrative oil-tank

2) Feeding is driven by gear and rack. All axes are equipped with the precise

planetary gear reducer

3) Pressure die is with semi-back function, and the following movable die is

reset by the air cylinder

4) Convenient operation, exquisite appearance, good machining technology

CNC system:

1) Standard type: 7" color screen, integrated keyboard, CNC control

2) Senior type: 12.1" color touch screen, 3D display, coordinates conversion,

industrial computer control (optional: animation simulation of bending

pipe, interference detecting)

Main technical parameters |

||

1 |

Max OD*W thickness |

OD 50X2.0mm(copper/aluminum) |

OD 43x1.5mm(iron/steel) |

||

2 |

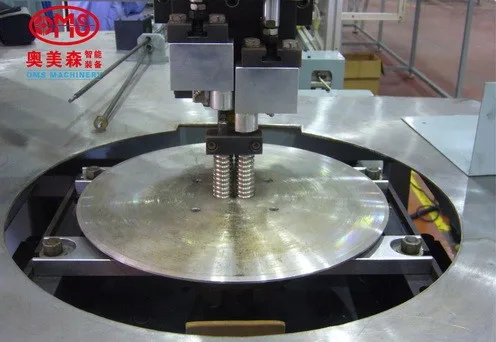

Max bending radius |

R250 |

3 |

Min bending radius |

R 45 |

4 |

Max work piece length |

3000(extensible) |

5 |

Travel of beeline feeding axis |

0-1800mm |

6 |

Speed of beeline feeding axis |

0-800mm/s |

7 |

Precision of beeline feeding axis |

±0.1mm |

8 |

Angle of spatial rotating axis |

0-±360° |

9 |

Speed of spatial rotating axis |

0-150°/s |

10 |

Precision of spatial rotating axis |

±0.1° |

11 |

Angle of bending axis |

0-190° |

12 |

Speed of bending axis |

40°/s |

13 |

Precision of bending axis |

±0.1° |

14 |

Integrative bending speed |

10s/bend |

15 |

Power supply |

3phase 4line 380v±10% 50hz |

16 |

Hydraulic power |

11kw |

The above parameters are for reference only subject to actual customer requirements