The long-standing company BITZER presents its product highlights for refrigeration at the Acrex 2016 trade fair in India (hall 5, stand M-3-4).

When cold is vital

- Energy-efficient solutions for medium and low temperature applications

- Robust reciprocating and screw compressors with infinite speed control

- Four Green Point service centres in India

Sindelfingen/Mumbai, February 25, 2016. Refrigeration compressor specialist BITZER is presenting its product solutions for India at the Bombay Convention and Exhibition Centre in the city of Mumbai between 25 and 27 February (hall 5, stand M-3-4).

Worldwide, India is the largest milk producer and the second largest producer of fruit and vegetables. According to German television network 3sat, 40% of food goes to waste before it reaches consumers. The main cause of this waste is infrastructure, which does not provide enough cooled storage facilities and transport options. Cooling and storage amenities are few and far between. If available at all, refrigeration systems often work overtime during the hot summer months and need to run on emergency power generators during the frequent power failures. BITZER offers suitable solutions based on a broad range of energy-efficient, safe and reliable compressors.

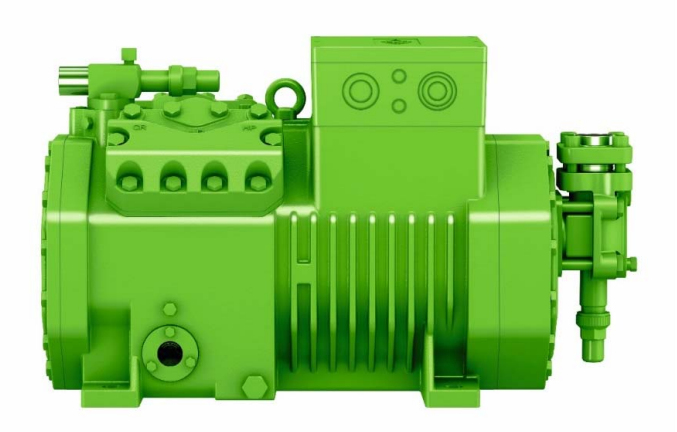

High cooling capacity with minimal energy requirements

The compact, semi-hermetic 4-cylinder reciprocating compressor in the BITZER ECOLINE series combines a high cooling capacity with minimum power requirements. Designed for operation between 25 and 70 Hz, it can be combined with any frequency inverter, providing users with infinite adjustment for the cooling capacity in their system. The compressor is very low maintenance thanks to its robust drive gear and sturdy valve plate design.

The semi-hermetic ECOLINE reciprocating compressors operate with almost all refrigerants, are highly versatile in their use thanks to two motor versions and run up to 12% more efficiently than their predecessors. Motor version 2 is designed to act as a universal compressor for medium and low temperature applications. Motor Version 1 is intended for heat pumps and special applications. The use of R134a with motor version 2 is particularly efficient and robust for medium temperature applications in high ambient temperatures. This combination is particularly popular in Europe due to its low carbon footprint.

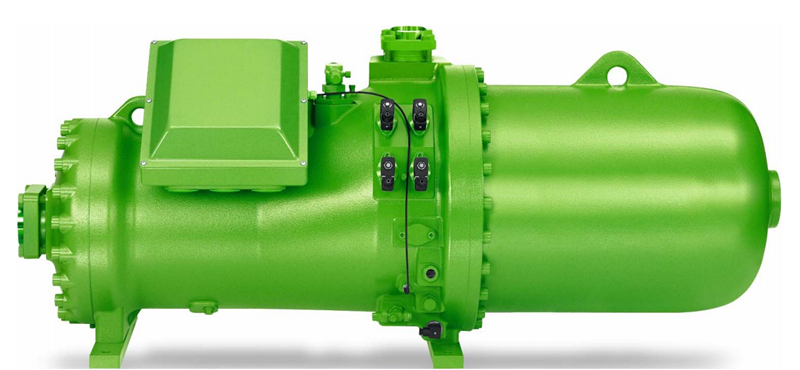

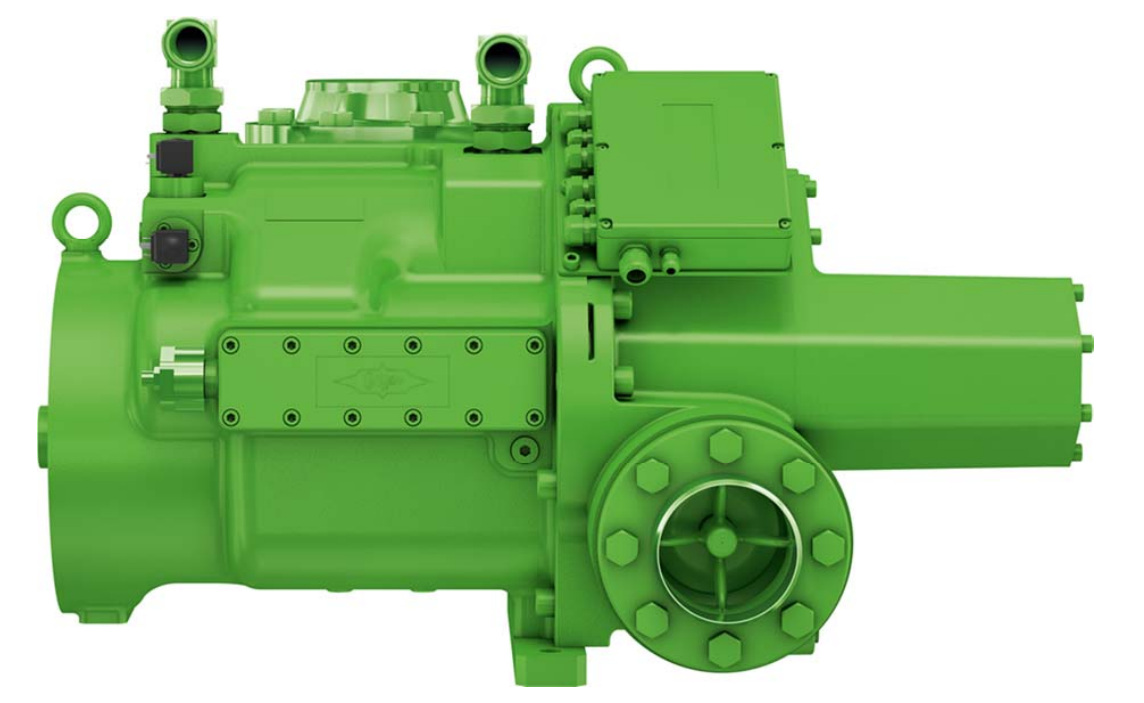

High cooling capacities in extreme ambient temperatures: CSH compact screw compressor

Semi-hermetic CSH compact screw compressors from BITZER are eminently suitable for air conditioning systems, heat pumps and short circuits. The application limits were designed for high condensing temperatures and pressure ratios, which result in excellent ESEER/IPLV and SCOP values. Their displacement is between 137 m3/h and 1,015 m3/h, depending on the model. Improved oil management enables compact screw compressors to achieve high cooling capacities even in extreme ambient temperatures. They can feature either a stepped or infinite control and operate up to 20% more efficiently than other compact screw compressors on the market.

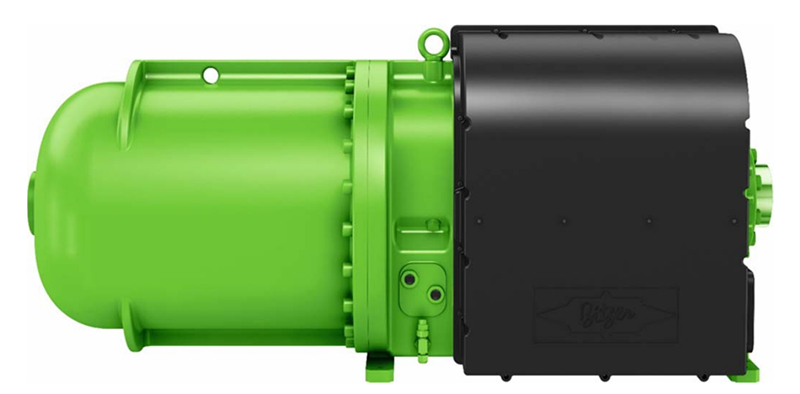

Greater flexibility – superior energy efficiency: BITZER CSV screw compressors

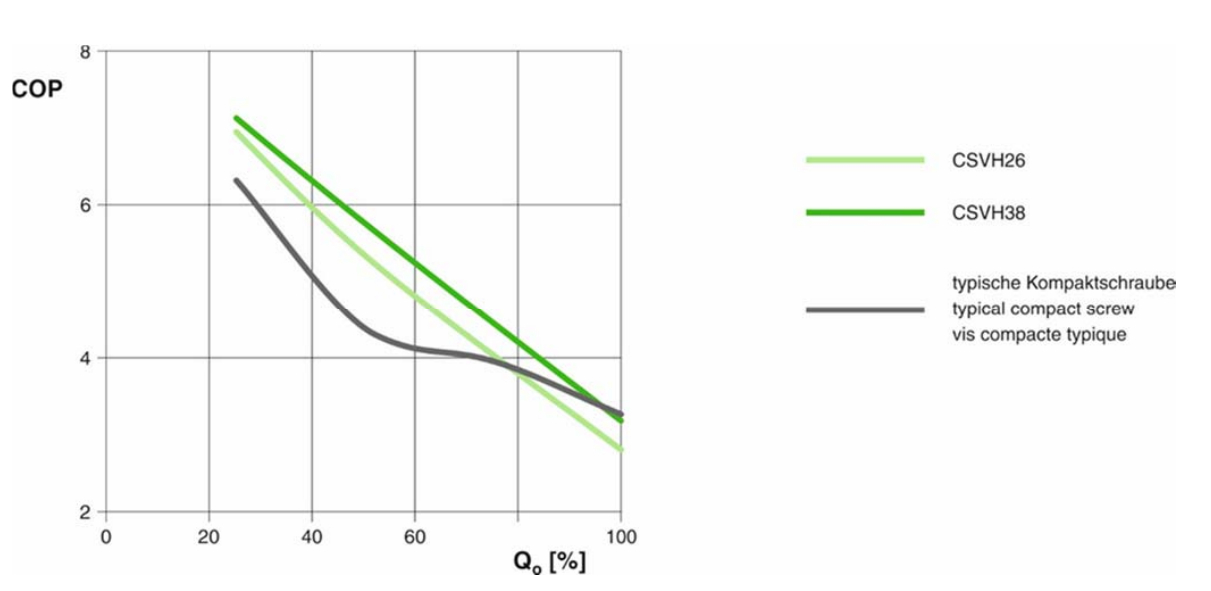

BITZER’s three CSVH2 screw compressors offer a unique benefit: optimized for use in air conditioning systems, heat pump applications as well as industrial and process cooling, the compressors are extremely efficient. BITZER has integrated the liquid-chilled frequency inverter into the compressor, and it’s carefully fine-tuned at the factory and configured for maximum efficiency. The result is an outstanding ESEER/IPLV value (see also image 4). The CSV series is therefore unrivaled among air cooled liquid chillers with dry expansion.

CSVH3: ESEER value over 6

With an ESEER value of more than 6, the intelligent compact screw compressor CSVH3 from the proven CSV series is setting benchmarks for air cooled liquid chillers. The CSVH3 series is particularly suitable for systems frequently operated under part-load and impresses due to its enhanced IPLV and SCOP values. The CSVH37 compact screw compressor has a cooling capacity of 550 kW (+5/50°C) and a displacement of up to 960 m3/h. The CSVH38 achieves an impressive cooling capacity of 660kW (+5/50°C) and a displacement of up to 1,156 m3/h. BITZER has created a new housing for this performance class.

All relevant parameters are accessible at any time via Modbus communication with the system controller. If compressors near their application limits, numerous protection and monitoring functions issue warnings before shut-off occurs. The integrated variable speed drive technology is precisely matched to the motor characteristics in CSVH compressors and improves efficiency compared to conventional frequency inverters. Additionally, CSV compressors are equipped with a Vi slider, making them extremely versatile and suitable for use in building air conditioning, heat pumps and process cooling.

OS.A95: displacement of 1,015 m3/h

With a displacement of 1,015 m3/h, the OS.A95 open screw compressor is the new flagship product for ammonia-based systems. Designed for applications with high performance requirements, it impresses with low life cycle costs. The OS.A95 screw compressor is suitable for industrial applications or use in warehouses, for example. A BITZER horizontal oil separator makes a compact design and a simple system structure possible. Since this compressor uses ammonia as a refrigerant, it is in line with the worldwide trend towards reduced pollutant emissions. It is the fruit of the 25 years’ experience which BITZER has gained in developing and manufacturing ammonia compressors.

Flexible thanks to BAHT

The trade fair also sees BITZER showcasing its ORBIT 6 and 8 scroll compressors, which are designed for use in air conditioning systems and heat pumps and for operation with R410A refrigerant. ORBIT compressors boast high isentropic efficiency, low sound levels and high energy efficiency. With displacements between 20 and 38 m3/h for the ORBIT 6 or 29 and 77 m3/h for the ORBIT 8, these scroll compressors are perfect for a wide range of applications.

With the help of the innovative BITZER Advanced Header Technology (BAHT), a single circuit assembly can incorporate up to 20 different output combinations. This boosts flexibility and efficiency while providing HVAC engineers with entirely new possibilities when configuring future systems. Thanks to BAHT, scroll compressors with different outputs can now be combined to form tandem or trio interconnected assemblies.

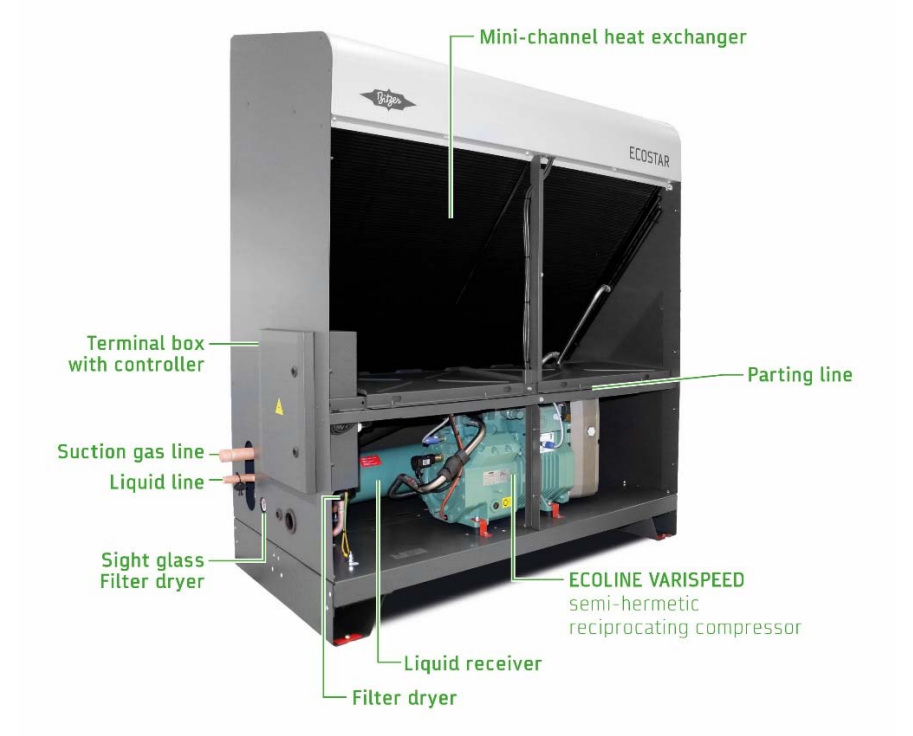

Efficient condensing units

The new air cooled ECOSTAR condensing units LHV5E and LHV7E with speed-controlled reciprocating compressors are particularly energy-efficient and offer many additional functions. Their control electronics are pre-wired in the factory and ready for operation, thus reducing the time and effort required for installation. Depending on the model, these condensing units are ideal for use with a wide variety of refrigerants, allowing BITZER to offer an extensive application range. With the LHV5E series, BITZER is introducing new models for low temperature applications, which feature a greater cooling capacity than existing solutions.

The two ECOSTAR condensing units help to save energy thanks to their intelligent controls. The control automatically adjusts the compressor speed and the controls for the power-saving EC fans to match the current cooling load or ambient temperature. Users can also use an Ethernet LAN connection or the Internet and a Modbus RTU to control and monitor condensing units remotely. Thanks to their improved mini-channel condensers, they require less refrigerant charge and transfer more heat than their predecessors in the ECOSTAR series.

Local service

BITZER supports its users worldwide in a variety of ways with its service and maintenance network Green Point. Specialists repair and service compressors with high-grade original parts at the four Indian Green Point subsidiaries in New Delhi, Mumbai, Kolkata and Bengaluru. Users also receive training and consultations at these locations, meaning that BITZER expertise is available at a local level.

The BITZER Group is the world’s largest independent manufacturer of refrigeration compressors with sales companies and production sites for reciprocating, screw, and scroll compressors as well as pressure vessels all over the globe. In 2014, 3,400 employees generated sales of €657 million.

Overview of images

Images may only be used for editorial purposes. This usage is free of charge if "Photo: BITZER" is given as the source and a complimentary copy is forwarded to us. Changes to the images – apart from cropping to the main motif – are not permitted.