- Products Details

Quick Details

-

Brand Name: YORK

Model Number: CYK Compound Centrifugal Chiller

Place of Origin: China (Mainland)

Packaging & Delivery

- Packaging Details: 90days

- Delivery Detail: --

Specifications

CYK Compound Centrifugal Chiller

We offer the best high-head performance solution at Johnson Controls with our YORK® CYK Compound Centrifugal Chiller. Designed specifically for high-head conditions and to handle applications with unique differential pressure, standard chillers just can’t compete with our CYK chiller.

The highly adaptable CYK Compound Centrifugal Chiller operates beyond the range of typical centrifugal chillers and incorporates a design using two centrifugal compressors that are arranged in a series to handle air-cooled, brine-chilling, and heat pump applications.

- Superior High-Head Performance – Compound chiller (2 compressors in series) offers superior performance on air-cooled, brine-chilling, ice thermal, and heat-pump applications.

- Greater Adaptability – To best match application requirements, each compressor can be optimized for the operating conditions.

- Superior Off-Design Performance – Capacity control on each compressor enables better performance at off-design conditions than is typical for multistage compressors.

- Lower Inrush Currents and Sound Levels – Multiple compressors mean lower inrush currents during start-up, and lower sound levels during operation.

- Quantum LX Control Center – Offers increased flexibility, superior serviceability, and remote access.

- Performance where standard chillers can’t compete

The MaxE™ CYK centrifugal chiller incorporates a design

using two centrifugal compressors arranged in series to

handle air-cooled, brine-chilling, and heat-pump applications

at conditions outside the range of typical centrifugal chillers.

These units use the same technology employed in the renowned

line of MaxE single-stage centrifugal chillers. Using HFC-134a,

MaxE CYK chillers are available in a wide range of capacities:

• For air-cooled applications (air-cooled radiators): 700 to

2,300 TR at 44°F LWT (2,500 to 8,100 kWR at 7°C LWT)

• For brine chilling: 700 to 1,600 TR at 20°F LBT (2,500 to

5,600 kWR at -7°C LBT)

• For heat pump applications: 11,000 to 38,000 MBH at 155°F

(maximum output temperature) 3,200 to 11,000 kWR at 68°C

(maximum output temperature)

The combination of standard components and unique

performance characteristics make MaxE CYK chillers the

technology of choice for jobs where standard chiller designs

can’t compete. Compound-system technology provides

energy and performance advantages for utilities, institutions,

and commercial facilities.

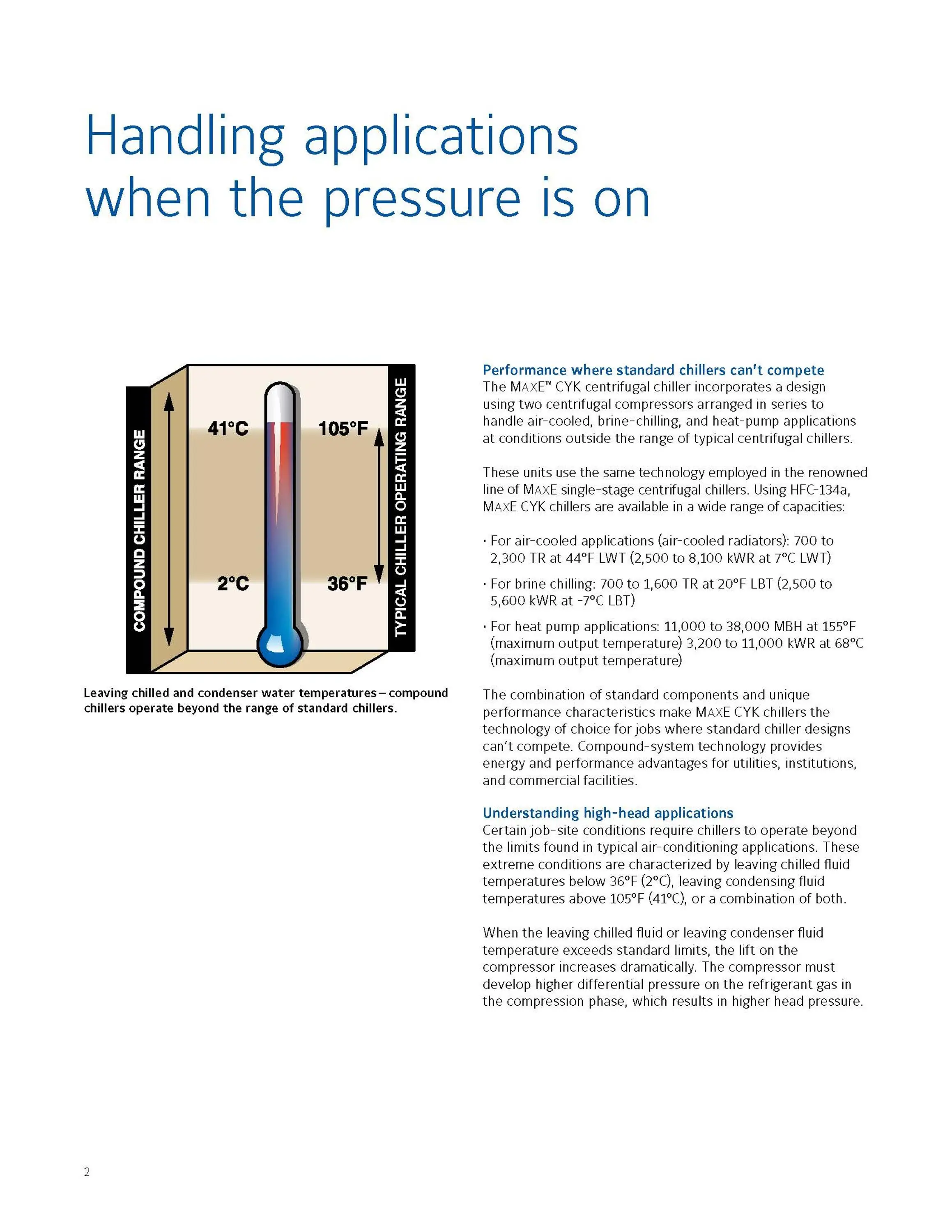

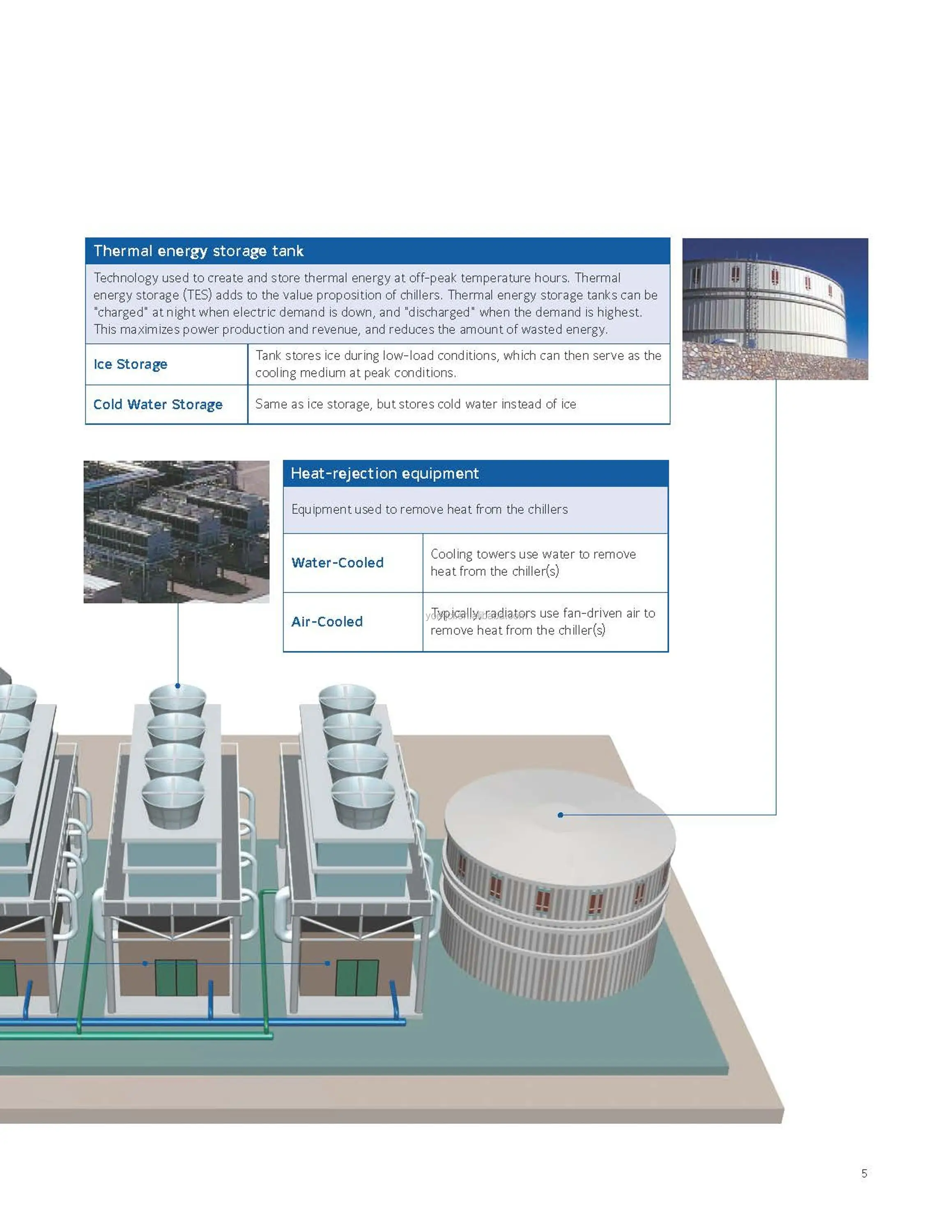

Understanding high-head applications

Certain job-site conditions require chillers to operate beyond

the limits found in typical air-conditioning applications. These

extreme conditions are characterized by leaving chilled fluid

temperatures below 36°F (2°C), leaving condensing fluid

temperatures above 105°F (41°C), or a combination of both.

When the leaving chilled fluid or leaving condenser fluid

temperature exceeds standard limits, the lift on the

compressor increases dramatically. The compressor must

develop higher differential pressure on the refrigerant gas in

the compression phase, which results in higher head pressure - High-head conditions are found in three typical

cooling applications:

1) Air-cooled radiators for water chilling in locations that

lack water for condensing.

2) Brine chilling for ice-thermal-storage applications and

for light industrial-refrigeration jobs.

3) Heat pumps for producing hot water with

simultaneous chilling.

High compressor head in brine applications is due to lower

evaporator temperature and pressure conditions. In heatpump

and air-cooled-radiator projects, it’s due to very high

condenser refrigerant temperature and pressure conditions.

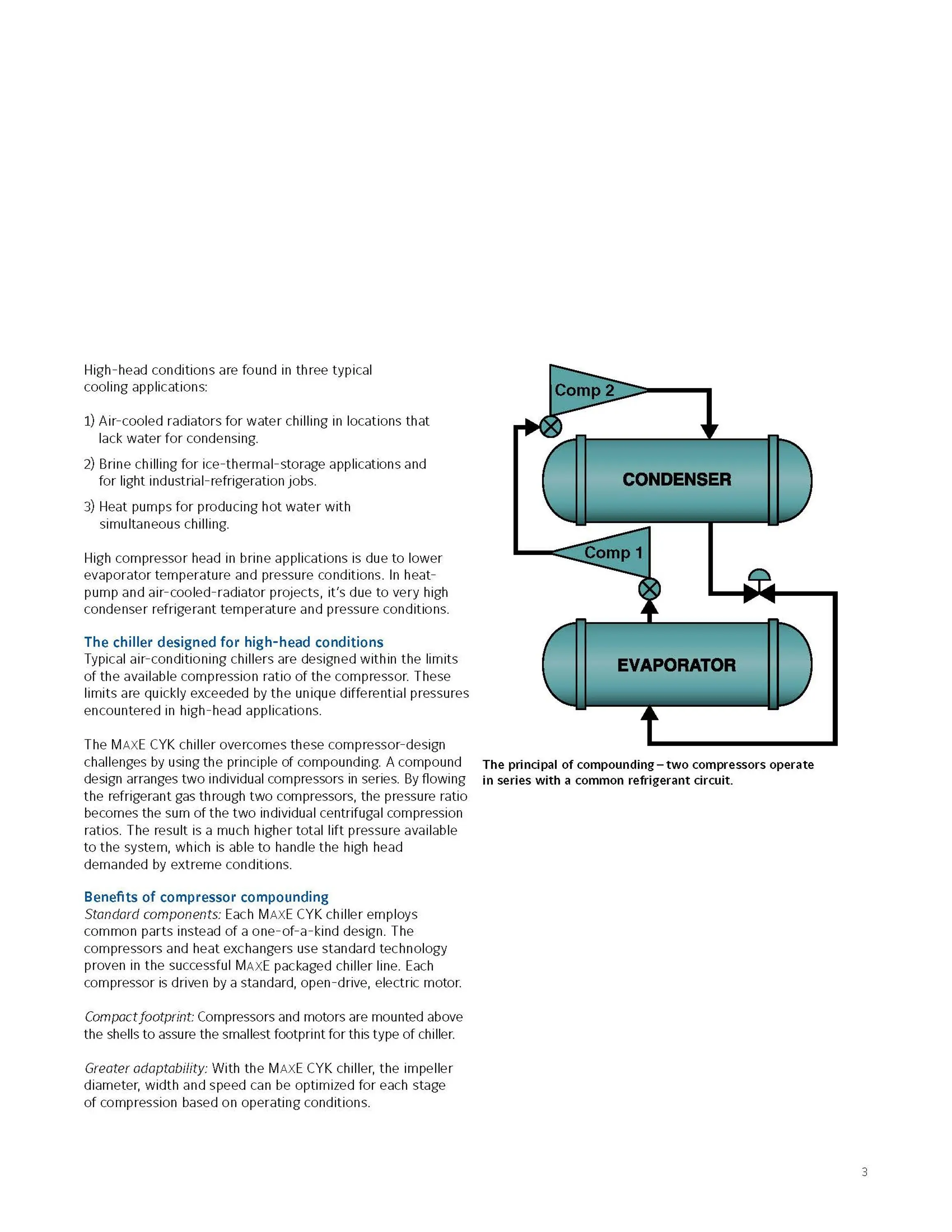

The chiller designed for high-head conditions

Typical air-conditioning chillers are designed within the limits

of the available compression ratio of the compressor. These

limits are quickly exceeded by the unique differential pressures

encountered in high-head applications.

The MaxE CYK chiller overcomes these compressor-design

challenges by using the principle of compounding. A compound

design arranges two individual compressors in series. By flowing

the refrigerant gas through two compressors, the pressure ratio

becomes the sum of the two individual centrifugal compression

ratios. The result is a much higher total lift pressure available

to the system, which is able to handle the high head

demanded by extreme conditions.

Benefits of compressor compounding

Standard components: Each MaxE CYK chiller employs

common parts instead of a one-of-a-kind design. The

compressors and heat exchangers use standard technology

proven in the successful MaxE packaged chiller line. Each

compressor is driven by a standard, open-drive, electric motor.

Compact footprint: Compressors and motors are mounted above

the shells to assure the smallest footprint for this type of chiller.

Greater adaptability: With the MaxE CYK chiller, the impeller

diameter, width and speed can be optimized for each stage

of compression based on operating conditions. - Superior part-load performance: Using a compound

arrangement allows the use of pre-rotation-vane (PRV) capacity

control for the centrifugal impellers of both compressors.

Pre-rotation vanes act like a throttle on the suction side of the

compressor to control compressor load. With PRV control on

both compressors, the result is better off-design performance

than for typical multistage compressors.

Handles varying condensing conditions: Since chillers spend

most of their time operating at off-design conditions, off-design

performance is a major factor in the energy-saving equation.

A compound chiller can operate with a wider range of

condensing-water temperatures than typical chillers. The

MaxE CYK chiller unit allows one compressor to be shut off,

so the chiller can run on just one compressor during low-head

conditions. This practice not only ensures system stability, it

allows the chiller to run more efficiently and takes advantage

of cooling-water temperatures well below design.

Lower inrush current: Instead of starting a single, large motor,

the MaxE CYK chiller stagger-starts the motors in sequence.

Consequently, peak inrush current is reduced to about 58%

compared to starting a motor for a single, large compressor.

Lower sound levels: Acoustically, with compound compressors

sharing the workload, compressor RPMs are lower than in

standard centrifugal designs — and lower RPMs help lower

sound levels.

Economizer option: An optional economizer is available to

further improve cycle efficiency for lower energy consumption.

Built-in reliability

An on-board control panel simplifies operation by managing

the staggered-start sequence of the compressors. The colored

graphical operator interface clearly displays operating

parameters, setpoints and alarms for quick response.

MaxE CYK chillers operate with environmentally responsible

HFC-134a refrigerant with zero ozone-depletion potential,

which eliminates chiller downtime for retrofit or replacement.

To further assure reliable performance, each MaxE chiller

is assembled at the factory. As an option, the unit can be

run-tested at design conditions prior to shipment.

For more information on innovative products designed

specifically for applications that are beyond the operating

parameters of standard chillers, contact your local Johnson

Controls representative. York (Wuxi) air Conditioning and Refrigeration Co. Ltd, Located in Wuxi National High-tech Industrial Park, Jiangsu province, China. Covers an area of 60000 square meters, of which the heavy machine factory building takes up 14,000 square meters. At present, the company has about 500 staffs, in the field of large-size units. York Wuxi is the largest manufacturer in Asia –pacific region with an annual output of more than 3600 sets. Its products not only top on market share in China, but also see tremendous growth in export in recent years.

York Wuxi has six production lines in total, of which five are automated lines, including one air-cooled screw production line, one large-size water-cooled screw unit production line, one small-size water-cooled screw unit production line, and two centrifugal unit production line. All production line adapt the DFT technology, being the first in the industry. The entire work process is compact and rational. With the efficient management method (such as four-color light), these lines have become the most compact, most efficient and most advanced production line in the industry.

York Wuxi is equipped with globally advance equipment in every step of its production process, including:

Most advanced plasma digital cutter which can be used under water

Efficient digital plate bending machine with a roll length up to 4.8 meters

LINCO DC submerged arc welder imported from USA which is the most advanced equipment in the world.

Most advanced digital drill press in the industry.

Four large-sized chiller comprehensive performance test branches, (test capacity per set up to 2000 cold tons, for 10KV high voltage tests and frequency conversion tests), presenting the most advanced level in China.

YORK (CHINA) introduced the Performance Excellence Mode since the beginning of its operation. This mode adopted by most world-class enterprises focuses on the customers. It learns, meets and exceeds the customers’ needs and serves society through its human-oriented strategy and corporate culture. Based on the effective QEHS management system and advanced management tools (e.g. six-sigma).YORK (CHINA) consolidates its leading status in the industry.

1. YORK RESEARCH AND DEVELOPMENT

In December 2004, to provide high-quality and competitive air conditioning products and refrigeration equipments to the Asia-Pacific region and on the parts of the world, YORK set up the YORK Asia Pacific research and development center in

Wuxi.

The center has the most advanced software systems, highly qualified professionals, and various test equipments and systems. The air-cooled test bench, unique in China and the largest in the

Asia-Pacific region, which has complete spring base for the equipment vibration test, can lower the noise to 20db by means of muffle devices. It also can carry out the working environment temperature simulation test by changing the indoor temperature via air conditioning and refrigeration system.

Since its establishment, the R&D center is dedicated to development efficient, energy saving, environment friendly products with independent intellectual property and unique technology and to the research of thermal conductivity, noise vibration and reliability to meet the needs of refrigeration &air conditioning in China and even the entire Asia-Pacific region. At the same time, the R&D center is also working closely with YORK international’s R&D division to develop money advanced products that can meet the global needs, In fact, innovation and renovation of many core technologies are happening in the Wuxi center.

2. YORK SEVICES INTRODUCTION

York Air Conditioning & Refrigeration Service Centre was established in 1993 in Shanghai. The Service Centre is now having stations in Beijing, Nanjing, Guangzhou, Xiamen, Wuhan and Shenzhen, and service representatives in Shantou, Changsha, Chengdu, Jinan, Dalian, Harbin and Hangzhou, and so on. Using our established service center networks throughout China, we are able to provide full after-sales services to all our customers in China.

At the same time, the service center is having a bonded spare parts warehouse in Shanghai. The spare parts warehouse will serve the spare part needs for our customers with minimum delivery time.

Qinhao Zhan

HVAC&R Engineer

Refrigeration and Process Systems

China Refrigeration (York by Johnson Controls)

Mobile:+86 13818154378 18625150627

QQ: 826554493

862417098

Johnson Controls York Industrial Refrigeration - Shanghai Jiusui-Ref Systems Engineering Co., Ltd.: harsh industrial environments breakthrough in industrial refrigeration + accuracy + = large cooling load fluctuations York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd tailor-made industrial refrigeration systems!

Provide personalized solutions for five major areas! Can be mainly used in petroleum, petrochemical process; chemical technology; synthetic rubber technology; fertilizer production process and chemical fiber textile technology. A number of other applications to meet different needs!

In addition to the above five major areas, York- Shanghai Jiusui-Ref Systems Engineering Co., Ltd Industrial refrigeration approved for use in air separation plants, liquefaction plants, carbon dioxide recovery systems, pharmaceutical industry, tobacco industry and steel plants, power plants, electronics factories and other process cooling And refrigeration systems.

York Shanghai Jiusui-Ref Systems Engineering Co., Ltd is located in the petrochemical industry, whether it is upstream natural gas compression, midstream liquefied natural gas storage, transshipment, or downstream air separation, liquefaction unit, as long as the compression-related York- Shanghai Jiusui-Ref Systems Engineering Co., Ltd are involved!

Advanced control system + energy efficient refrigeration equipment + overall solution = York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd a full range of food refrigeration business!

Food processing + large cold storage + poultry slaughter + beer drinks + dairy products + aquatic fisheries + small logistics distribution center, etc. = York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd food refrigeration business coverage!

P.K. "China cold village" -58 ℃ low temperature! (-28 ℃ ~ 15 ℃), and even tuna low-temperature cold storage (-55 ℃ ~ -60 ℃), York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd food refrigeration business can be, but also the production of cold storage, Complete turnkey project. Diverse demand one stop to meet! Supporting cold storage products with cooling water system to meet the dairy products, beer and other light industry diverse needs. Sea and land to eat to ensure the quality of fish and shrimp! Provide on board and onshore fish and shrimp processing supporting the cooling and quick-frozen products, stable and reliable products to York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd frozen food business filled with full.

Hot summer experience! Not only in the game-type ice rink and entertainment ice rink unique advantages, but also for the automatic ice-making plant and ice cream factory to provide frozen solution.

Scale: Above 1000 People

Country/Region: China (Mainland)/Asia

Established: 2015

US 6181-87111 / Pack 1 Pack/Packs (Min.Order)