- Products Details

Quick Details

-

Brand Name: WELLWALL

Model Number: WW-W2

Place of Origin: Wuxi, China

Specifications

Anticorrosive silencer and smoke exhaust duct plate WW-W2

Anticorrosive silencer exhaust air duct sheet WW-W2 is made of double sided embossed coated steel plate and new microporous material. Its structure is: the middle layer is new microporous material, and the upper and lower layer is embossed colored steel plate. It has good steel and strength, corrosion resistance, weatherability and silencing performance. It can resist impact effectively. The impact resistance can be compared with the traditional iron pipe, which is stronger than the inorganic glass steel wind pipe. It avoids the destruction of the cross construction process, the combustion performance is a non combustible A and the fire resistance limit is 120min, mainly used. The manufacture of fire and smoke exhaust pipes can also be used as fireproofing boards.

Antiseptic and silencing and smoke exhaust duct product features:

1, anticorrosive silencers and smoke exhausting pipes, the fire resistance limit is 120min, which is in line with the national standard "GB/T17428-2009".

2, anticorrosion: the use of embossed color steel plate on the exterior and outer surface of the antiseptic and antiseptic smoke exhaust fan, to enhance the anti-corrosion ability of the smoke exhaust pipe, is widely used in the basement and other places with larger humidity.

3, soundproof: the inner and outer surface color steel plate is a new microporous material, which can effectively isolate noise.

4, noise reduction: the inner surface color steel plate does not need to make stiffeners, while the use of Diamond Flower correction to reduce resonance, reduce the noise generated by resonance.

5, heat insulation: core thermal conductivity is 0.025W (W.K), the insulation performance is equivalent to 30-50mm thick glass cotton.

6, light weight: the same specification of smoke exhaust pipe, the weight of antiseptic and silencing products is only 1/4 of white iron pipe weight; the cost of hoisting material is relatively reduced, 2 people can complete the hoisting, reduce labor cost and improve work efficiency. At the same time, it conforms to the code for seismic design of building electrical and Mechanical Engineering (GB50981-2014), and saves aseismic support and hangers.

7, high strength: the highest can withstand the wind pressure of 3000Pa to meet the application of high, medium and low voltage systems.

8, less loss: according to the need of wind pipe production, we can generate different lengths of plates, minimize material loss and improve production efficiency.

9, the wind pipe is easy to manufacture: plate cutting is made by hand or mechanical tool, through the button metal alloy flange connection, lifting is simple, and the construction period is short.

10, the installation of anticorrosive silencers and smoke exhausting pipes does not need to reserve construction space, which can reduce the height requirement of buildings, save engineering costs, and increase the use space.

Product specification: long (900MM to 6000MM) * wide 1200MM* thick 10MM.

Technical indexes:

Anticorrosive silencer exhaust air duct sheet WW-W2 is made of double sided embossed coated steel plate and new microporous material. Its structure is: the middle layer is new microporous material, and the upper and lower layer is embossed colored steel plate. It has good steel and strength, corrosion resistance, weatherability and silencing performance. It can resist impact effectively. The impact resistance can be compared with the traditional iron pipe, which is stronger than the inorganic glass steel wind pipe. It avoids the destruction of the cross construction process, the combustion performance is a non combustible A and the fire resistance limit is 120min, mainly used. The manufacture of fire and smoke exhaust pipes can also be used as fireproofing boards.

Antiseptic and silencing and smoke exhaust duct product features:

1, anticorrosive silencers and smoke exhausting pipes, the fire resistance limit is 120min, which is in line with the national standard "GB/T17428-2009".

2, anticorrosion: the use of embossed color steel plate on the exterior and outer surface of the antiseptic and antiseptic smoke exhaust fan, to enhance the anti-corrosion ability of the smoke exhaust pipe, is widely used in the basement and other places with larger humidity.

3, soundproof: the inner and outer surface color steel plate is a new microporous material, which can effectively isolate noise.

4, noise reduction: the inner surface color steel plate does not need to make stiffeners, while the use of Diamond Flower correction to reduce resonance, reduce the noise generated by resonance.

5, heat insulation: core thermal conductivity is 0.025W (W.K), the insulation performance is equivalent to 30-50mm thick glass cotton.

6, light weight: the same specification of smoke exhaust pipe, the weight of antiseptic and silencing products is only 1/4 of white iron pipe weight; the cost of hoisting material is relatively reduced, 2 people can complete the hoisting, reduce labor cost and improve work efficiency. At the same time, it conforms to the code for seismic design of building electrical and Mechanical Engineering (GB50981-2014), and saves aseismic support and hangers.

7, high strength: the highest can withstand the wind pressure of 3000Pa to meet the application of high, medium and low voltage systems.

8, less loss: according to the need of wind pipe production, we can generate different lengths of plates, minimize material loss and improve production efficiency.

9, the wind pipe is easy to manufacture: plate cutting is made by hand or mechanical tool, through the button metal alloy flange connection, lifting is simple, and the construction period is short.

10, the installation of anticorrosive silencers and smoke exhausting pipes does not need to reserve construction space, which can reduce the height requirement of buildings, save engineering costs, and increase the use space.

Product specification: long (900MM to 6000MM) * wide 1200MM* thick 10MM.

Technical indexes:

| Number | Inspection items | Technology index | Measured value |

Test method |

| 1 | Apparent density | >=2kg/m2 | 3kg/m2 | GB/T 6343-2009 |

| 2 | Combustion performance | >=A2 | A2 | GB8624-2012 |

| 3 | Duration of fire resistance |

>=1.5h | 2h | GB17428-2009 |

| 4 | Air flow max | <=20M/S | 20 | GB50243-2002 |

| 5 | Pressure in duct max | <=3000Pa | 3000 | GB50243-2002 |

Scale: 101 - 200 People

Country/Region: China (Mainland)/Asia

Established: 2017

You May Like:

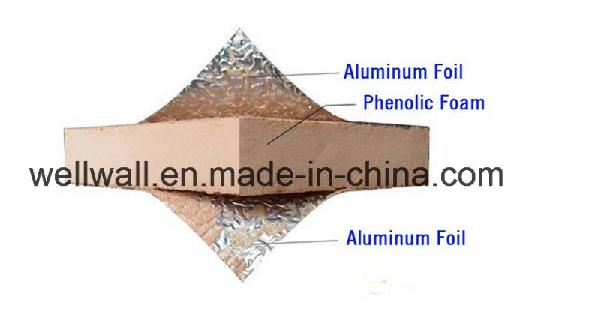

Popular Phenolic Foam Insulation Composite Air Duct Panel Sandwich Panel Manufacturer

US 1-10 / Square 1000 Square (Min.Order)

US 1-10 / Square 1000 Square (Min.Order)

Air Conditioning Ducting Fireproof Insulation Aluminum Foil Phenolic Foam Panels

US 1-10 / Square 1000 Square (Min.Order)

US 1-10 / Square 1000 Square (Min.Order)

HVAC 20mm Aluminum Foil Phenolic Foam Insulation Board for Air Duct

US 1-10 / Square 1000 Square (Min.Order)

US 1-10 / Square 1000 Square (Min.Order)

High Quality Phenolic Foam Insulation Block Air HVAC Vertination Aire Duct

US 1-10 / Piece 1000 Pieces (Min.Order)

US 1-10 / Piece 1000 Pieces (Min.Order)