U-SHAPE DUCT PRODUCTION LINE 5 DUCT AUTOMATIC FORMING

- Products Details

Quick Details

Packaging & Delivery

- Packaging Details: wooden box package

- Delivery Detail: Shipped in 15 days after payment

Specifications

U-SHAPE DUCT PRODUCTION LINE 5 DUCT AUTOMATIC FORMING

| U Shape Air Duct Production Line 5

|

Performance Features:

1. Honest strengthens the basis in the pursuit of customer satisfaction and constant innovation

helps customers to achieve the goals.

2. During feeding mechanism with pneumatic servo manipulator helps to ensure stability and

speed of the machine, and the accuracy of its locating system.

3. It only takes 20-25 seconds to make one L-shaped workpiece and the efficiency will double

comparing with the linear type.

4. Without moving back and forth the fixed locking machine is able to improve the efficiency.

5. All the rolling reels are made of bearing steel so that the lifetime prolongs by more than 5 times.

6. Under the material-saving mode of CNC system, waste is less than 20 mm per roll.

7. With production memory functions, the production orders can be tracked and checked.

Function:

It's mainly for TDF / angle steel / C-shaped flange forming with daily processing capability of

1000-2500 square meters. Only with inputting dimensions in duct, production line can

automatically complete uncoiling, leveling,beading, punching, shearing, locking, forming TDF /

angle steel / C-shaped flange and folding.

Main import Configuration:

| 1. Beijing Huade + hydraulic system from Taiwan |

| 2. Japan Omron encoder |

| 3. Taiwan Hiwin linear guideways |

| 4. Schneider electrical system |

Basic Configuration:

| 1. Two electric coil cradles, 4 material trays (5-7 t each roll) |

| 2. One rack |

| 3. One host (line 2 host) |

| 4. Two stainless steel roller convey platforms |

| 5. One fixed joint locking machine |

| 6. One duplex TDF flange forming machine |

| 7. One duplex angle steel flange forming machine |

| 8. One servo feeding platform |

| 9. One hydraulic folding machine |

| 10. One set of computer controlling system |

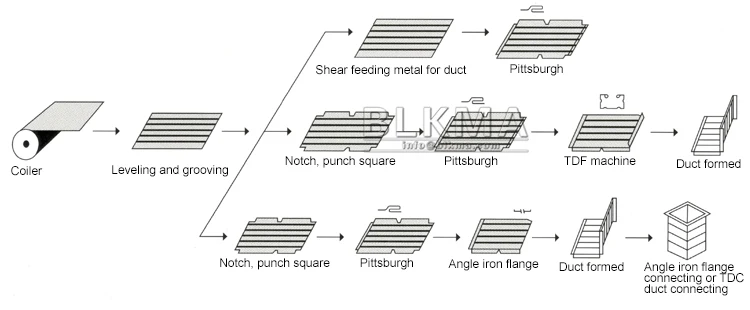

Working Schematic Diagram:

Working Flow:

Main Technical Parameters:

| Model | Sheeting thickness (mm) |

Max width (mm) |

Max working speed (m/min) |

Max weight of coil (T) |

Dimension (mm) |

Power (kw) |

Weight (T) |

||

| SADL-5U-1250 | 0.5-1.2 | 1250 | 15 | 7 | 14000 | 5000 | 1500 | 30 | 13 |

| SADL-5U-1500 | 0.5-1.2 | 1500 | 15 | 7 | 14000 | 5400 | 1500 | 30 | 14 |

Video on Youtube:

https://www.youtube.com/watch?v=f661qAAhJHY

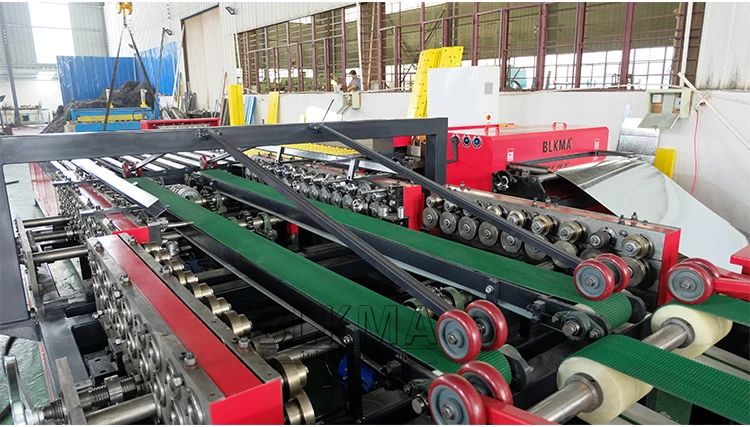

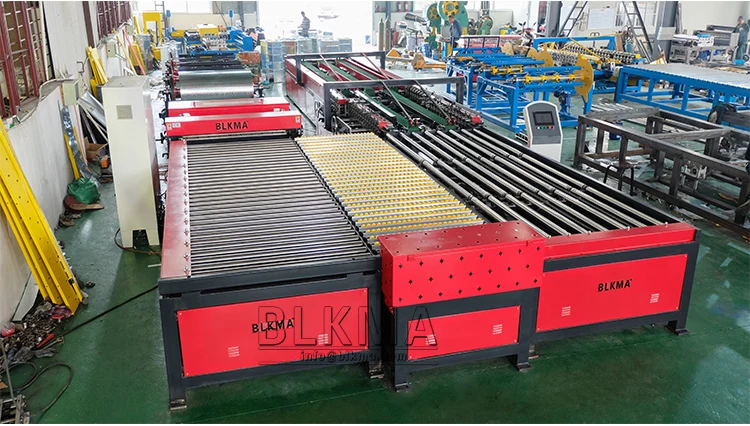

| Detailed Images |

| Factory Show |

Packing & Delivery |

Scale: 501 - 1000 People

Country/Region: China (Mainland)/Asia

Established:

US 35000-55000 / Set 1 Set/Sets (Min.Order)

1000 Piece/Pieces (Min.Order)

1000 Piece/Pieces (Min.Order)

1000 Piece/Pieces (Min.Order)

1000 Piece/Pieces (Min.Order)

1000 Piece/Pieces (Min.Order)

1000 Piece/Pieces (Min.Order)

1000 Piece/Pieces (Min.Order)

- Min.order FOB Price

- ≥1 Set US 50000.00