Cr12 carbon steel tube welding mould

- Products Details

Quick Details

-

Brand Name: JinPin

Model Number: Depends on Tube's model,diameter and material

Place of Origin: Shandong, China (Mainland)

Packaging & Delivery

- Packaging Details: 1.Inner package: water-proof and shock-proof plastic and choth. Outer package:firming wooden cases 2.Special requirement according to your request

- Delivery Detail: Within 20 days after your advanced payment

Specifications

Cr12 carbon steel tube welding mould

Mould style |

Breakdown/forming rolls

Fin pass rolls

Welding rolls

Sizing rolls

Turk’s head rolls |

Mould material |

Cr12( D3 ), Cr12MoV ( D2 ) Cr12Mo1V1 (SKD11) H13 Any special material according to your requirement |

Produced Pipe Shape and size |

round steel pipe:Φ8(mm)-Φ711(mm)

square steel pipe: can be as large as 600*600(mm)

cold roll forming pipe: U-shape W-shape Z-shape steel sheet pile, color coil, section bar and so on

any special shape can be customer-made |

Strong hot sell point |

1. advanced groove design

2. strict analysis and inspection of raw materials

3. special heat treatment technology

4. precision machining

5. advanced quality control system |

1.Pipe mould: steel tube, plum tube, flat tube, oval tube, fan-shaped tube, polygonal tube, single and double groove pipe, tube frame, special-shaped mould, etc.

2. Selection: To produce first-class pipe mould, we must have first-class raw material. We choose hign-quality tool steel Cr12mov as raw materials, mouild steel Cr12mov material set high wear resistance, toughness, resistance to high pressure, high hardness, hard quenching.

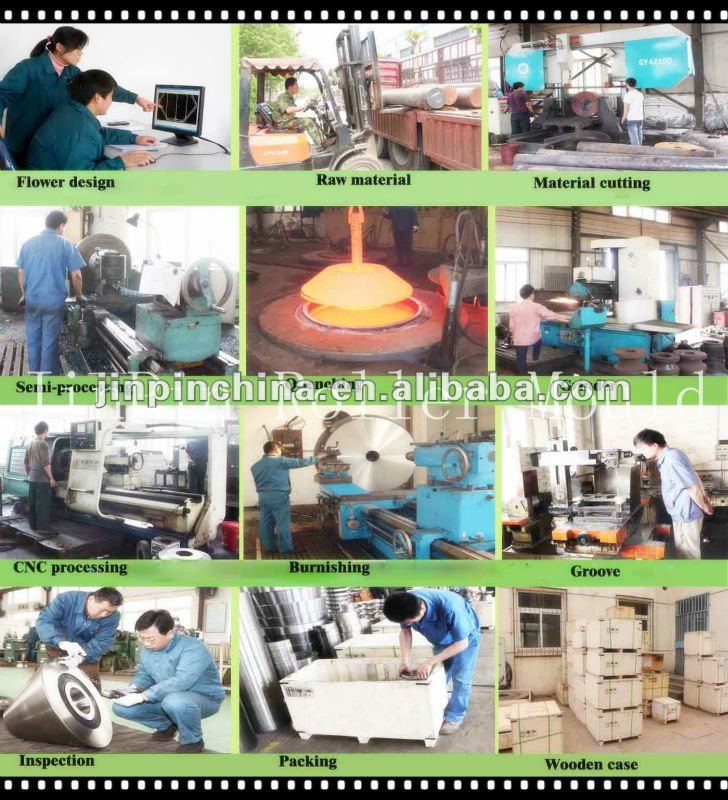

3. Maching process: Raw materials- materials testing- exercise- saws- turning- drilling- turning- CNC precision turning- grinding- quenching- hardness test- internal and external grinding- test- boxing.

4. Features: Mature manufacturing process, experience and standard production management achievements leading provider of technology per crown. CNC machining of Japan, high precise; 10 years experience in RD, the fingerprints, mechanical pattern, on the corner, concave angle phenomena, and to form tolerance of roundness in les than 0.05mm, square tube on the angle does not exceed ±0.05mm.

Mold processing line

Advanced groove deformation technology

We have an engineer group with really good technical skills.

Strict raw material control

We will check the raw material first with the digital ultrasonic flaw detector. If the rarw material has problems,we will not use it in the production.

Professional heat treatment technology

Precise machining

Strict test

We test the raw materials, the semi-finished products and finished products strictly.

Packaging & Shipping

1.Inner package: water-proof and shock-proof plastic and choth.

Outer package:firming wooden cases

2.Special requirement according to your request

Produced Pipe Shape and size

1. round pipe: Φ8(mm)-Φ711(mm)

2. square pipe: min 10*10(mm)

max 600*600(mm)

3. Other type of pipe: U-shape, P-shape, Z-shape, and so on

Satistics of forming results

Payment Terms

1. Paypal or Aliexpress for small amount.

2. for mass order: By T/T, 30% deposit after order confirmed, balance to paid before shippment.

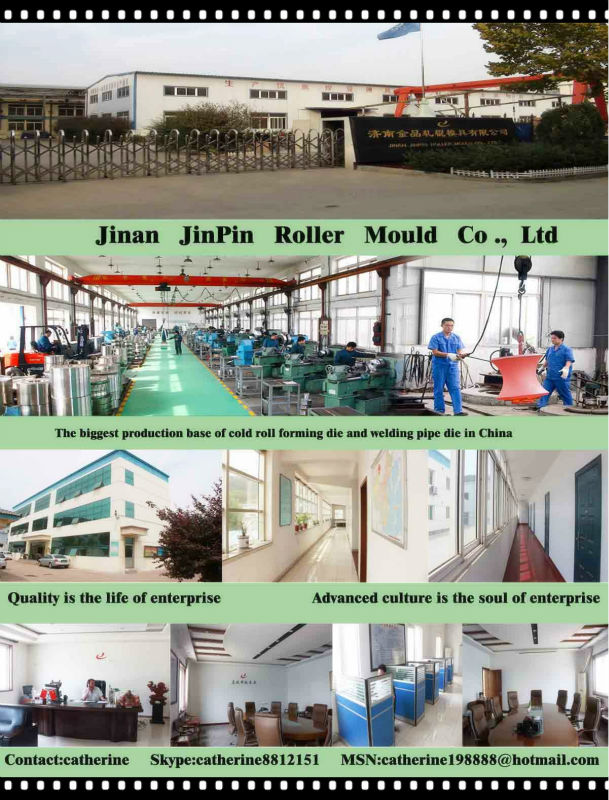

Our company

Established in 1994, Jinan Jinpin is a composite company which can design and manufacture high frequency tube welding equipments, rollers, ferrite rods and cold roll forming equipments. Its main

products are various types of high frequency tube welding equipments, cold forming steel units,

ferrite rods, welded pipes, cold bending moulds and magnetic rollers for hot galvanizing line etc.

The company has three branches with a total staff about 200 people. It has strong technical strength

and processing capacity. The high chromium alloy, which is the wear-resistant materials, developed

by the company independently obtained national patent, and has been successfully applied to its

rollers manufacture. The rollers’ service life is 1.5 times of the common ones. The high frequency

tube welding equipments, researched and developed by itself , have automatic adjustment function,

need not to replace the rollers in the rough forming section. Time , effort and cost saving achieved.

Scale: 101 - 200 People

Country/Region: China (Mainland)/Asia

Established:

US 0.1-0.4 / Piece 50 Piece/Pieces (Min.Order)

US 0.2-10 / Piece 50 Piece/Pieces (Min.Order)

US 0.2-10 / Piece 50 Piece/Pieces (Min.Order)

US 0.2-10 / Piece 50 Piece/Pieces (Min.Order)

US 0.2-10 / Piece 50 Piece/Pieces (Min.Order)

US 0.2-10 / Piece 50 Piece/Pieces (Min.Order)