- Products Details

Quick Details

-

Brand Name: JINPIN

Model Number: HG32/HG50/HG76/HG127

Place of Origin: Shandong, China (Mainland)

Packaging & Delivery

- Packaging Details: Wooden case which is suitable for long diatance transportation Any special packing according to our requirement

- Delivery Detail: Within 3 month after your advanced payment

Specifications

Slitting line is definitely used to cut wide strip coil into several narrow strip coils for use as raw material by high frequency pipe welding line or other cold roll forming lines,It is characterized by high running speed,

high automation degree,high positioning accuracy,wide application range,and easy operation.They can be operated in mechanical mode,hydraulic automatic mode or computer control mode.

Slitting line can be categorized into thin strip slitting line and thick strip slitting line for the thickness of the strip or copper strip slitting line, silicon steel, stainless steel, aluminum, carbon steel strip slitting line, etc for the material processed.

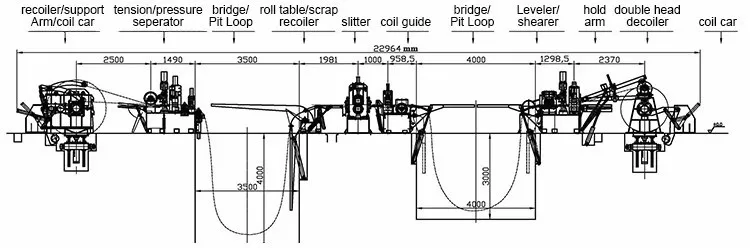

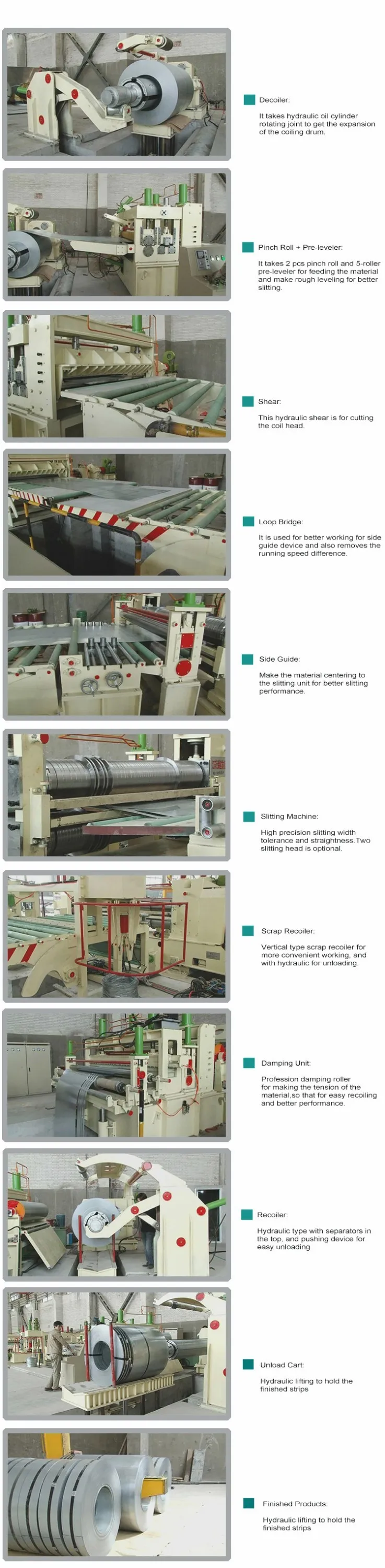

Component

1.Loading coil car 2.Uncoiler

3.Straightener device 4.Pinch roll&leveler & hydraulic shearer

5.Loop pit 6.Side guide

7.Slitter 8.Transition platform & scrap winder

9.Loop pit 10.Tension station

11.Recoiler 12.Unloading coil car

Main technical parameter

Material: Cold-rolled, hot-rolled carbon steel, galvanized steel.

Material thickness:0.3-3.0mm

Material width:800-1250mm

Coil I.D.: Φ508mm/Φ610mm

Coil O.D.: ≤Φ2000mm

Coil weight:20 tons max

Narrowest strip width slit into: 25mm (strip thickness≤1mm)

Width cutting precision: ±0.05mm(strip thickness≤1), ±0.1mm(strip thickness>1.5mm)

Slitting Bur: 0.03minimum, 5% of the trip thickness

No. of slitting: 25no.(thickness1mm), 12no.(thickness2mm), 7no.(thickness 3mm)

Line working speed: 150m/min max

Total power: Approx.210kw

Usually, you just provide some basic parameters, and then we can offer a slitting line machine for you

(1) Material of the steel coil

(2) The thickness of the sheet

(3) The width the steel coil

(4) The original coil Inner diameter

(5) The original coil outer diameter

(6) The maximum weight of one original coil

(7) The maximum slitting strips quantity

(8) The output coil Inner diameter

(9) The output coil outer diameter

(10) The maximum weight of output coil

(11) Slitting machine speed requirements

(12)Production output, daily output / monthly output

Slitting line machine is usually be customized according to customer's requirements, As long as you provide parameters and requirements for us, and then we designed for you a suitable machinery equipment scheme.

(1) What is your advantages?

A1:More than 15 years experience in manufacturing the machines. Professional and humanized .

A2:We are a manufacturer, not the trading company. So we can provide the strong and powerful service before and after sales.

A3: Can produce 3-4 lines per month.

(2) Do you have after sales support?

Yes, We have a 25-person -professional and strong installation team. And Will provide the machine life time service for you. Any problem , contract us and we will solve for you.

(3)How to visit your company?

Our factory is located in Jinan city, Shandong Province. So there are two ways to our city. One is by flight, direct to Jinan Airport. Another is by train, direct to Jinan station or Jinan West Station. We will pick you up at the station or airport

(4)What information you need to prepare the quotation:

1. coil thickness(min-max)?

2. coil width(min-max)?

3. what is your steel material ?

4. weight of your coils(max)?

5. how many pieces need to slit for max thickness?

6. how many tons you need per day or per month?

Scale: 101 - 200 People

Country/Region: China (Mainland)/Asia

Established:

US 50000-1000000 / Set 1 Set/Sets (Min.Order)

US 50000-1000000 / Set 1 Set/Sets (Min.Order)

US 50000-1000000 / Set 1 Set/Sets (Min.Order)