welding pipe rods industrial magnetic rod flexible magnetic rod used for welding pipes

- Products Details

Quick Details

-

Brand Name: JinPin

Model Number: 200mm

Place of Origin: Shandong, China (Mainland)

Packaging & Delivery

- Packaging Details: 1.Carton Carton Box/Wooden Case . 2.Special packaging according to clients' requirments.

- Delivery Detail: Within 10 days after receiving the deposit.

Specifications

welding pipe rods, industrial magnetic rod,

flexible magnetic rod used for welding pipes

Basic characteristic

1.Mn-Zn ferrite for welding steel pipe

2.Saturation flux density for 3200Gs

3.Curie temperature for 300

4.Length:150(mm),200(mm)or customer-made

5.The famous branch known as "JinPin" branch

6.Experience for 20 years with ISO9001:2008 Certificate

| Product name | high frequency welding ferrite cores; outside diameter 3-102mm , length 200mm-300mm |

| Material | Mn-Zn ferrite |

| Style | Hollow round/Fluted hollow |

| Standards (D*L*d) | outside diameter from 3mm-102mm,length 200mm-300mm. |

We also can produce the special style according to our clients requirments. |

|

| Features | 1.High breakout of fire |

| 2.quick welding | |

| 3.Good mechanical property | |

| 4.Long service life |

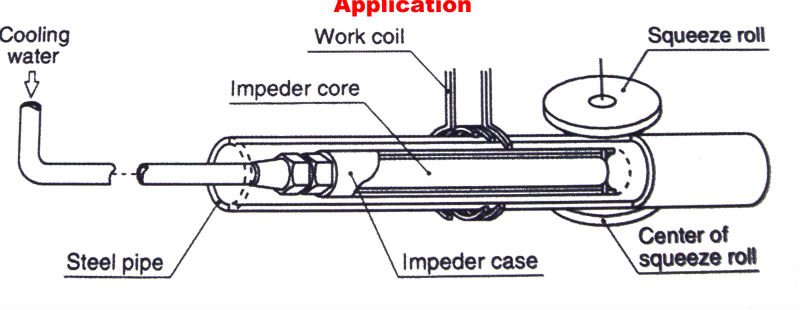

Application

10 pcs/panel, 60 pcs/ctn; 12cs/ panel, 96pcs/ctn, and cusomized packing.

Jinan Jinpin Co., Ltd. |

Established in 1994, Jinan Jinpin is a composite company which can design and manufacture high frequency tube welding equipments, rollers, ferrite rods and cold roll forming equipments. Its main products are various types of high frequency tube welding equipments, cold forming steel units, ferrite rods, welded pipes, cold bending moulds and magnetic rollers for hot galvanizing line etc.

Over the years, it provides a large number of equipments and service to the industries of metallurgy, automobile, railway, construction, petroleum, electric power, coal and the key projects of China. Its projects are throughout of China and the products are exported to Southeast Asia, the Middle East, Eastern Europe, South America and many other international markets.

The company has three branches with a total staff about 200 people. It has strong technical strength and processing capacity. The high chromium alloy, which is the wear-resistant materials, developed by the company independently obtained national patent, and has been successfully applied to its rollers manufacture. The rollers’ service life is 1.5 times of the common ones. The high frequency tube welding equipments, researched and developed by itself , have automatic adjustment function, need not to replace the rollers in the rough forming section. Time , effort and cost saving achieved. |

Scale: 101 - 200 People

Country/Region: China (Mainland)/Asia

Established:

US 0.3-6 / Piece 10 Piece/Pieces (Min.Order)

US 3-6 / Piece 10 Piece/Pieces (Min.Order)