- Products Details

Quick Details

-

Brand Name: YUTONG

Model Number: HNT

Place of Origin: Henan, China (Mainland)

Packaging & Delivery

- Packaging Details: Plywood case professional packaging transportation

- Delivery Detail: Within 15 working days

Specifications

1.Stable shell temperature

2.Indirect heating and cooling

3.Prevent secondary pollution

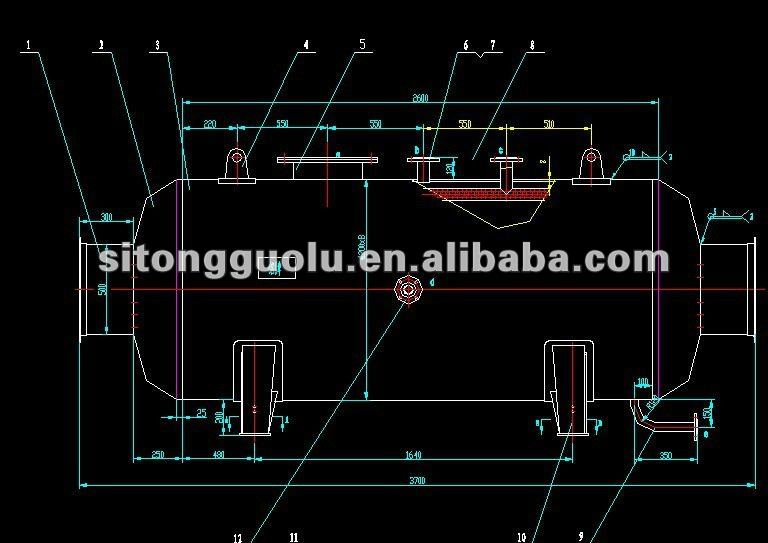

Detailed description of heat recovery boiler

Introduction:

1) Waste heat boiler tube, activity by pot smoke hoods, for the oven, the flue duct, section 1 2 period at the end of the duct, 1 period, the flue duct, feeding tube for 2 (the material to slip) trough, oxygen, nitrogen, sealing device and muzzle nitrogen sealing plug, manhole, micro differential pressure take pressure device, the flue of bearings and hanger etc.

2) Waste heat boiler is divided into six circuit for each circuit, by the fall and rise of the pipe, water pot cylinder from each flue pipe down into each through the lower gas-holding pipes flue enter each box after heating water heating, through the generation after the steam into the collection box, again by imports rose tube into the tube. All are with flange connection between the flue.

Working Principle:

1. High temperature flue gas combustion equipment out of the flue transported to the waste heat boiler superheater flows through the entrance, again, evaporator and economizer, finally the chimney discharged into the atmosphere, exhaust temperature of 150 ~ 180 °C for general, high temperature flue gas temperature from the exhaust temperature drop to the release of the heat used to make water into steam.

2. Boiler water supply first into the economizer, water in the economizer in absorption of heat to drum up slightly below under pressure of saturated temperature into the pot tube. Into the pot of water and the cylinder cylinder of saturated water in, after mixing tube down at the bottom of the pan to absorb heat tube evaporator came in steam, is usually only part of water into steam, so in the flow of the steam in the mixture is soda.

3. Soda mixture into the upper left evaporator pot tube through the separation of separation equipment, the pan tube internal waters space impinges into decline in steam, heat tube to continue and steam from the superheater tube into the pot, heat absorption make saturated steam into the superheated steam.

4. According to the production of steam process three stages, that is, three corresponding heating the economizer, evaporator and superheater, if don't need the superheated steam, need to be saturated steam, can not ship superheater. When there are hot steam, can be added a heaters.

Factory

Customer Visiting

Scale: 101 - 200 People

Country/Region: China (Mainland)/Asia

Established:

US 1000-6000 / Unit 1 Unit/Units (Min.Order)

US 1000-12000 / Unit 1 Unit/Units (Min.Order)

US 1500-99000 / Set 1 Set/Sets (Min.Order)