Corrosion resistance rotary air preheater cold end layer enamel coated sheet

- Products Details

Quick Details

-

Brand Name: HTEG

Model Number: Customized

Place of Origin: Shandong, China (Mainland)

Packaging & Delivery

- Packaging Details: Seaworthy Packing

- Delivery Detail: Shipped in 15 days after payment

Specifications

Corrosion resistance rotary air preheater cold-end layer enamel coated sheet

Specification

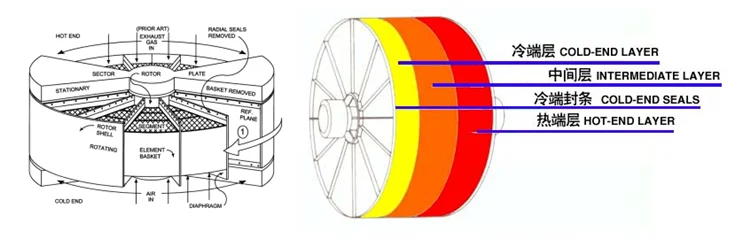

Corrosion resistance rotary air preheater cold-end layer enamel coated sheets are a compact arrangement of profiled metal sheets placed in the Air Preheater rotor in two or more layers and plays the most important role in the process of heat recovery. The bottom layer, or the cold end layer, is where the air enters and the flue gases are discharged, and is therefore, subjected to severe corrosion due to acid dew point. The Material of Construction and the Profile design of the Heating Elements depends on the operating conditions, quality and type of fuel, etc.

Features of air preheater cold-end layer enamel coated sheets

1.Compact structure and occupying less space

2.A significant reduction in overall size and weight

3.Easy and economic replacement of the heating surface with separate cold and hot end packs

Enameled corrugated sheet details

Inquiry now

Application

The rotating-plate design (RAPH) consists of a central rotating-plate element installed within a casing that is divided into two (bi-sector type), three (tri-sector type) or four (quad-sector type) sectors containing seals around the element. The seals allow the element to rotate through all the sectors, but keep gas leakage between sectors to a minimum while providing separate gas air and flue gas paths through each sector.

Related productions

Our Company

Shandong Hengtao Energy Saving & Environment Protection Co., Ltd. established in 2003, which is specialized in designing, manufacturing, engineering, supplying of boilers, boiler components and boiler auxiliaries.

Our main products including CFB boiler, coal fired boiler and boiler parts such as tubular air pre-heater, rotary air pre-heater, super heater, re-heater, header, membrane water wall and economizer. We are also the provider for boiler integrated energy-saving solutions and we have EPC qualification.

Workshop & Packing & Shipment

Clients

Hengtao products have been exported to Mongolia, Turkey, Thailand, Vietnam, Indonesia, India, Iran and other oversea countries and areas.

Certifications

Grade A boiler manufacturing; installation and contract of electromechanical equipment; EPC qualification for electric power engineering construction; installation, transformation and maintenance qualification of Grade 1 boiler and A2 pressure vessel manufacturing. We also have ISO, TUV, ASME, SGS ect. certifications.

FAQ

Q:Who are you? Trade Company or manufacturer?

A: We are manufacturer and we have our own trade company.

Scale: 501 - 1000 People

Country/Region: China (Mainland)/Asia

Established:

US 1400-2500 / Ton 1 Ton/Tons (Min.Order)

US 1400-2500 / Ton 1 Ton/Tons (Min.Order)

US 1500-1550 / Ton 1 Ton/Tons (Min.Order)

US 1400-2500 / Ton 1 Ton/Tons (Min.Order)

US 1600-2000 / Ton 1 Ton/Tons (Min.Order)

US 1600-2000 / Ton 1 Ton/Tons (Min.Order)

US 1600-2000 / Ton 1 Ton/Tons (Min.Order)

- Min.order FOB Price

- ≥1 Ton US 1550.00

- ≥10 Ton US 1500.00