Industrial Certificated Economizer for Boiler on Sale

- Products Details

Quick Details

-

Brand Name: HTEG

Model Number: boiler economizer

Place of Origin: Shandong, China (Mainland)

Packaging & Delivery

- Packaging Details: Seaworthy Package

- Delivery Detail: Shipped in 3 days after payment

Specifications

Boiler Economizer

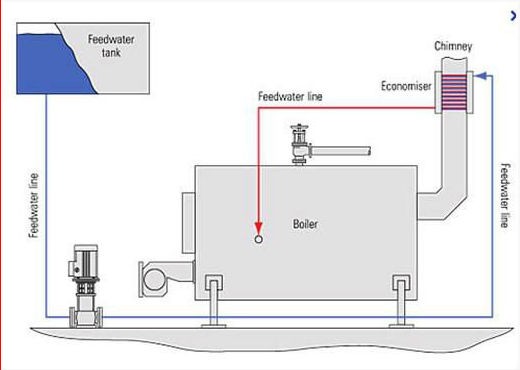

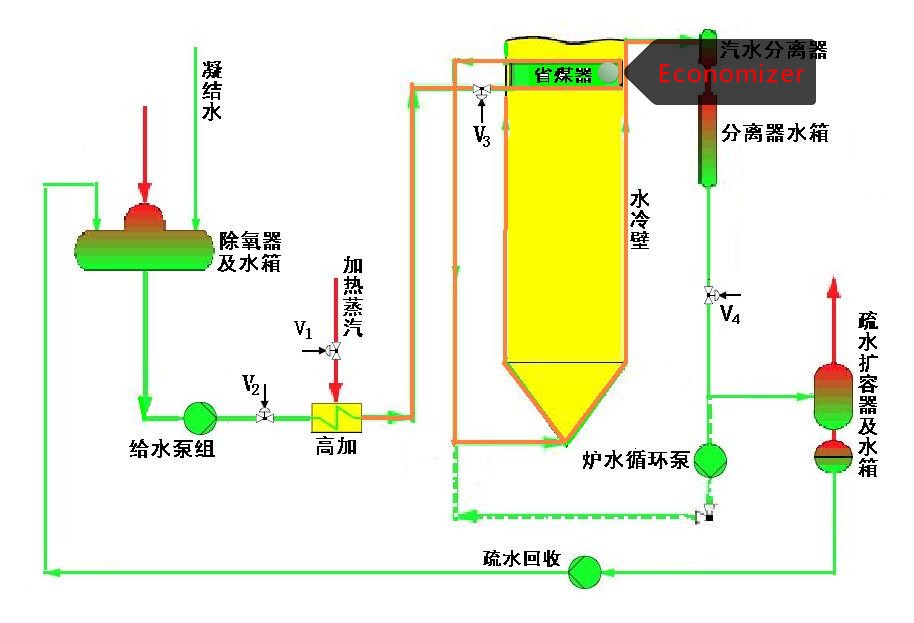

Economizers are tube heat exchangers located in the top section of a boiler. They raise the feedwater temperature to slightly below saturation temperature. Economizers are so named because they can make use of the enthalpy in fluid streams that are hot, but not hot enough to be used in a boiler, thereby recovering more useful enthalpy and improving the boiler's efficiency. Economizers preheat the cold water used to fill water wall panels.

Application:

Economizers consist of parallel-mounted steel tubes, butt welded and bent, and subject to the highest pressures and lowest temperatures. They need good mechanical strength at metal temperatures up to 380 °C (and/or steam temperatures up to 330 °C). Accordingly, they are usually made of carbon steel.

When you purchase a thermal fluid heater, the cost of fuel to operate the heater is a major concern. The amount of fuel needed is related to the thermal efficiency of the heater. Increasing its thermal efficiency reduces the amount of fuel needed as well as operating costs.

An effective way to increase a heater’s thermal efficiency and reduce fuel costs is to install a special heat exchanger in the heater’s exhaust stack. The heat exchanger recovers heat from the exhaust stack that would otherwise be lost into the atmosphere.

This special type of heat exchanger is known generically as an economizer or convection section. It consists of an enclosure that contains coils of pipe, and the enclosure fits between the heater and the bottom of the exhaust stack.

Performance characteristics:

(1) Excellent anti-wear performance

(2) Less fouling

(3) Compact space

(4) Welded Joints less

Warranty

1.One year warranty

2.Spare parts available at ex-factory price

3.Different voltage available

4.100% tested before delivery

5. Assist clients to prepare for the first construction, and also can arrange engineer on-site instruction of installation and commissioning

Our Company

Our company produce all kinds of wear-resistant, heat-resistant, corrosion-resistant alloy castings. Our company developed enamel tubular Air Pre Heaters, corrosion resistance, wear resistance, surface smooth, non-blocking ash flow resistance is small, life-style of the original steel preheater 5 times more reasonable structure, easy installation and maintenance, be able to protect the safe operation of the boiler unit.

Our main products including CFB boiler, coal fired boiler and boiler parts such as tubular air pre-heater, rotary air pre-heater, super heater, re-heater, header, membrane water wall and economizer. We are also the provider for boiler integrated energy-saving solutions and we have EPC qualification.

Scale: 501 - 1000 People

Country/Region: China (Mainland)/Asia

Established:

US 1450-1650 / Ton 1 Ton/Tons (Min.Order)

US 1600-2500 / Set 1 Set/Sets (Min.Order)

US 1600-2500 / Set 1 Set/Sets (Min.Order)

- Min.order FOB Price

- ≥1 Ton US 1540.00

- ≥10 Ton US 1500.00