Product Description

FEATURES

FEATURES

D series modular air-cooled scroll chillers are well-developed products incorporated with multiple advanced technologies. It mainly features the low noise level, compact structure, easy and safe operation, and convenient maintenance and service etc., widely used at newly built or retrofitted industrial and civil buildings in various sizes, such as, hotels, apartments, restaurants, office buildings,

shopping malls, theaters, gyms, workshops, hospitals and other places where there are high requirements on noise level and air but the cooling tower is going to be installed troublesomely.

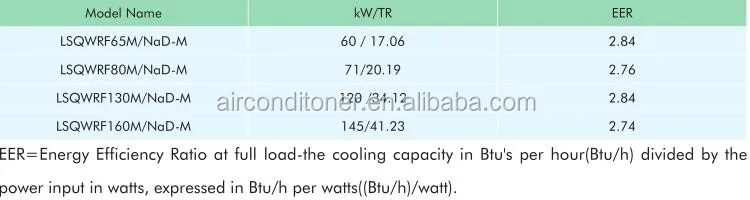

D series modular air-cooled scroll chillers are constructed of one or up to 16 single units which may varies in structure and in capacity of either 65NaD, 80NaD(two independent refrigeration cycle) or 130NaD,160NaD (four independent refrigeration cycle) so as to build up a array of products with the cooling capacity ranging from 60 to 1160kW.

High energy efficiency

It is initially certified as one of the energy-saving chiller products in China

Free master unit design

Any single unit can operate as the master once connected with the wired controller. It overcomes the problem which would occur to the product of other manufacturer that the whole system would fail to work properly when the fixed master unit malfunctions

Excellent compatibility

Each chiller is constructed of up to 16 single units of 65NaD, 80NaD or up to 8 single units of 130NaD ,160NaD

Hermetic scroll compressor

Compared with other type of compressor under the same cooling load, it has few movable components, smaller rotating torque, lower noise and vibration and higher reliability and efficiency.

Super protection

It is equipped with the top-end microcomputer control system which is capable of providing well-rounded protection and self-diagnosis.

High reliability

It is constructed of well-designed refrigeration parts for multiple refrigeration cycles adequately guaranteeing the reliable operation.

Compact structure

The modular design enables the compact structure, reduced volume, light weight, easy handling and shipping and flexible installation.

Low noise

The unit runs with low noise and vibration, widely applicable for various projects.

Quiet mode

The unit is allowed to run in the quiet mode based on the user’s requirement, which can not only save energy but also create a comfortable and pleasant living environment.

Economy mode

The unit can run in the economy mode without lessening the air conditioning effect so as to cut down the electricity consumption.

Equilibrium running

It indicates each compressor will run alternately so as to extend their service life.

Humanized alert

When the unit runs out of the allowable temperature range, an alert will rise on the display.

Powerful remote monitoring

Gree centralized air conditioning system can be perfectly integrated to the BMS or Gree remote monitoring system through the BACnet interface and realize communication through the RS485.

The chiller's Unit Control Module is an innovative, modular microprocessor control design. It coordinates the actions of the chiller in an efficient manner and provides stand-alone operation of the unit. A Human Interface Panel is a standard component of the Chiller. Access to all unit controls is via the Human Interface Panel.

Compressor In-built protection device: Motor winding temperature, discharge gas temperature and

phase reversal for direction of rotation.

Crankcase heaters: Protects the unit against refrigerant migration, oil dilution and potential compressor failure.High pr essure switch: Provides protection in case of excessive discharge press-ure.Low pressure switch: Provides protection in case of unsafe low suction pressure.

When the flow passage of the shell-and-tube heat exchanger is frozen up, it would cause serious damage to the heat exchanger, such as cracking and leakage which are out of warranty, therefore, the user should take measures stated below for freeze protection.

1. Under subzero conditions, it is necessary to shut down the chiller installed outdoor and then drain

the evaporator completely.

2. Failure of the chilled water flow switch and the anti-freezing temperature sensor will cause the tube

frozen up, so the flow switch shall be interlocked with the chiller.

3. When charging or recovering the refrigerant, the evaporator would crack because of frostbite

provided the refrigerant pressure inside the evaporator is under 0.71MPa. Therefore, be sure to

keep the water flow continually inside the evaporator or drain it completely.

Dimensions

Rigging Instruction

Each unit will undergo a series of strict factory inspections and tests to guarantee the expected performance and quality. However, special attention should be paid during handling and shipping to prevent the control system and the piping system from being damaged. It is best to unpack the chiller at the installation location and keep the chiller upward. When the chiller is unpacked during handing, please follow the lifting instructions stated below.

a. Move the chiller by placing three levers 1/5 wider than the width of the chiller under the base and

meanwhile always keep the chiller in balance.

b. See the figure below for more details

Installation Interspace

Installation Interspace

A minimum spacing of 1m should be left between any two modules for unobstructed air intake and equipment service. Additionally, a minimum of 2m should be kept between the chiller and any barrier. If allowable, it would be better to set up a suncover 3m ahead of the chiller.

Packaging & Shipping

Packaging :Wooden Case for Large Sized Outdoor Unit,Carton for Small Sized Indoor Unit.

shipment detail:

Warehouse showing:

Our Services

1,Proposal and consulting

You could tell us your request,then we can give you solution

2,Desing

Design on the basis of professional research and development strength, the best system, flow analysis, economic analysis, load calculation and equipment selection

3,Technical Installation team

4,Installation Materials Adopted.

5,Warranty Policy:

We guaranty 18 Months warranty for the products.

A.Repair include:compressor/fan motor/control panel/Receiver modules,thermal controller and other spare parts.

B.Because all the quality issues we should bear the cost maintenance and spare parts.

One of the following does not belong to the scope of the repair,But fees may apply maintenance

1,Damages caused during the transportation,load,installation which made by upload, transportation ,installation principal.

2,During the debug,damages caused by inappropriate test behaviors should be on charge by the debug team.

3,After debugging is completed and the equipments can be work normally,any mistaken manual operations made by the users should be on charge for the damage.

4,Any movements,dissemble and repair /maintenance operated by other company or person which leads to damage should be on response.

5,Natural disasters result from force majeure.

Company Information

Beijing Xinfayuan Trading Co.,Ltd proud to count as one of the most dynamic Chinese suppliers in the sectors of the central air conditioners, electric devices as well as in the heating industry. The main products of our range include: air conditioners, hot air pumps for water heaters, electric devices and building materials with high technology for an optimal quality of service.

Main Markets::Middle East,South East Asia,Africa,Europe,North America etc.

Annual Export Value:10 Million US Dollars.

Welcom to visit our websit,we will provide the best product and the best service.

Company name:Beijing xinfayuan Trading.Co.Ltd

Name:linda

phone:0086-13811011496

skype:zghtlinda