Brand Name: yongda

Model Number: WZP-90

Place of Origin: Henan, China (Mainland)

Yongda super good quality IGBT energy saving protable induction heater for bolts

IGBT portable induction heater for bolts has many advanges:

1. One time can heat 3-5 pieces steel bars,depend on diameters and machine power.

2. Water cooling induction heating machine ,ensure machine 24 hours continuous working

3. Complete protecting functions:over current, over voltage, lack of phase, lack of water, OC.Reset, timer etc. 4. When any alarm lamp light, machine stop heating, prevent it damaged, until trouble shooting, start heating again.

5. IGBT modules, full solid state induction heating machine, energy save 30%-50% than traditional high frequency tube machine or other heating metod,such as coal heating stove.

6. Induction coils are easy to change, customized coils, according to size of work pieces.

7. No-contacting work pieces , safe and reliable.

Model |

Input voltage |

Input current |

Oscillation frequency |

Cooling water pressure |

WZP-40 |

320-420V |

2-40A |

15-30KHZ |

0.1MPA |

WZP-60 |

320-420V |

3-60A |

15-30KHZ |

0.2MPA |

WZP-90 |

320-420V |

4-90A |

15-30KHZ |

0.3MPA |

WZP-120 |

320-420V |

6-120A |

15-30KHZ |

0.3MPA |

WZP-160 |

320-420V |

6-160A |

15-30KHZ |

0.3MPA |

WZP-200 |

320-420V |

6-200A |

15-30KHZ |

0.3MPA |

WZP-300 |

320-420V |

6-300A |

15-30KHZ |

0.3MPA |

WZP-400 |

320-420V |

6-400A |

8-15KHZ |

0.3MPA |

WZP-500 |

320-420V |

6-500A |

8-15KHZ |

0.3MPA |

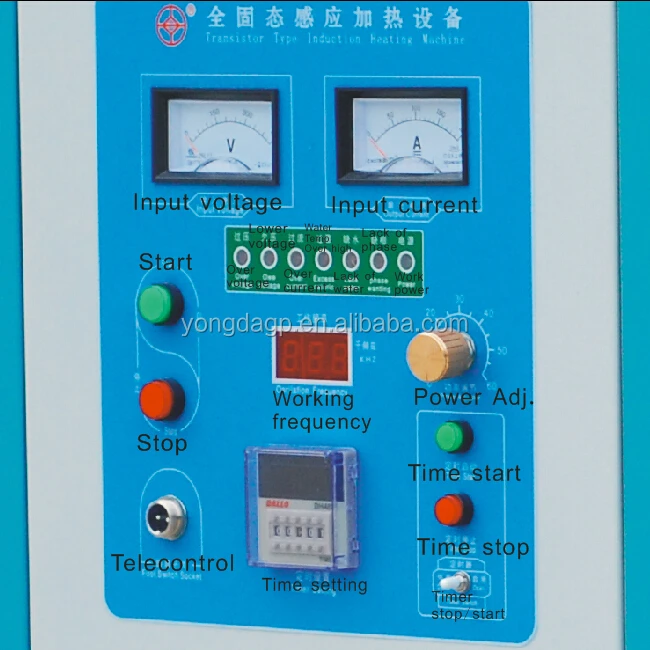

Cotrol panel of igbt portable induction heater for bolts

Full protection: has over voltage,over current,temperature is over high,lack of water, lack of phase,etc, alarm lamps indicators. can automaticly control and protection the machine itself.

1, Throuh heating forging all kinds of standard parts, fasteners, machinery parts, hardware tools, straight shank twist drill of hot forging, hot rolling, metal annealing. Such as: tensile steel; wire, nail wire heating; stainless steel annealed, rose type.

2, heat treatment various types of hardware tools, electric, hydraulic, pneumatic components, automotive, motorcycle parts and other mechanical parts of the surface of the metal, the hole, partial or total quenching. Such as: hammer, knife, scissors, pliers and all kinds of shafts, cams, sprockets, gears, valves, ball stud, a large machine tool guide, ductile iron quenching.

3, brazing welding various types of brazing carbide blade, turning, milling, planing, reamer, diamond saw blade, serrated welding; grinding, drilling, cutting welding; brass, copper, stainless steel pot, etc. hybrid welding of metallic materials.

4, metal melting: melting gold, silver and copper.

5, other areas of plastic pipe heating cable, heating wire coating; food, beverage, pharmaceutical industry, the use of aluminum foil.

induction heater for bolts

Shenqiu Yongda High Frequency Equipment Co., Ltd. was founded in 1996, which belongs to high-tech enterprise in Henan Province,China. We are located in Shenqiu County, Zhoukou City. We professionally dedicated to R&D,production of HF,SSF,MF induction heating equipment,adhering to the spirit of innovation, mean while strengthening cooperation with domestic well-known universities and research institutions. We are the leader of domestic induction heating field, and got the ISO9001:2000 international quality management system certification in August, 2004. Up to now, we has 83 office in domestic ,products hot sale , and also exported to Europe,America,and Southeast Asia etc. other regions.

Our factory

Products applications:

Metal forging,hardening,brazing, annealing, melting,shrink fit, thermal compound,plastic machine screw cylinder heating etc. other fields.

Packing of induction heater for bolts :

1.Carton or wooden cases (plywood) Inside,will be filled with plastic foam,for waterproof and shockproof.

2.Accessories: induction coils,foot switch and installing and operating instructions

3. Size : generator 830*500*880mm transformer 830*600*550mm

4.Weight: 110kgs -120kgs

4.Shipping: by sea LCL(less than container load) or by air.

Packing machines photo

1. Reply your inquiry within 24 hours

2. Recommend suitable machine model,according to your work piece specifications and heating requirements.

3. Send detailed product parameters, photos and price.

4. Solve all the problem , such as shipping cost, shipping time,delivery time, warranty etc,what you concerned.

5. Reach an agreements, sign proforma invoice or contract.

6. Produce induction heating equipment strictly based on the PI/contract.

7. Arrange goods shipment

8.Tracking goods and help you install and operating machines.

9. Email or Call visit.

10.Provide long-terms technical support.

Dear buyer:

please kindly tell us your work piece specifiations, heating requirement etc. by whatsapp/trademanager/email etc.

Thanks for your reading !