Brand Name: yongda

Model Number: WZP-60

Place of Origin: Henan, China (Mainland)

China Supply induction heating power, induction heating power supply, induction heating coil

YONGDA IGBT induction heaters adopt the latest MOSFET, IGBT power units and frequency conversion control techniques with high efficiency, low energy consumption and higher output power. With constant current and constant power control function to greatly optimize the heating process of metals, realize efficient and fast heating, and fully exert the superiority of the products. Power consumption is half of traditional electron tube high frequency induction heating equipments under the same conditions. With 100% load design, can work for continuous 24-hour a day. Infrared temperature detector can be equipped to realize the automatic control of temperature, improve heating quality and simplify manual operation. With heating-insulating-cooling three stages function setting, the heating and insulating time required can be get to accommodate to the batch and repeated heating situations. With multiple status display of overflow, over voltage, low water, phase failure and load malfunction, providing higher reliability and sustainability. Select power supply according to the power and frequency. The higher the frequency, the shallower the heating depth, and the lower the frequency, the better the diathermancy.

Technical parameters of WZP-60 induction heating power supply

Model |

WZP-60 |

Work power |

3 phase 380V+/-10%, 50-60HZ |

Input voltage |

320V-420V |

Input current |

6-60A |

Oscillation frequency |

10-50 KHZ |

Cooling water pressure |

0.1 MPA |

Size of geneartor: Transformer |

generator590*330*650mm transformer 500*360*455mm |

Weight of generator ; transformer |

41kgs;37kgs |

Water cooling protection point |

Below 50 degree celsius |

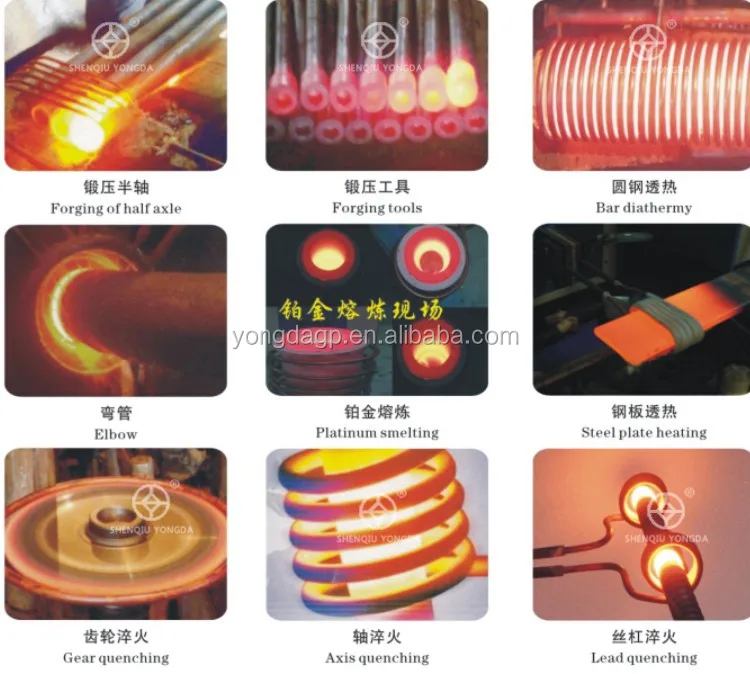

Applications of induction heating power

Heat treatment (induction quenching/hardening/tempering):

Welding (brazes welding, silver soldering and brazing):

Annealing (tempering and modulation):

Application photos

Photos of Induction heating power supply

Q: Why use induction heating?

A: 1,Induction Heating is a GREEN process as it does not emit fumes or CO2 into the environment, emissions are controlled by the electricity generating company at one site and are easy to monitor.

2, The result of only a small proportion of the material being heated, commonly less than 5% of the mass being heated to accomplish the required properties, then there is less energy consumed, overall, to heat treat the component when compared with conventional furnace heat treatment methods.

3, Again due to the small areas heated there is a considerably reduced heat treatment distortion so much so that the majority of the components we heat treat are ready for assembly after heat treatment.

4, Grinding costs can constitute 25 - 30% of the total cost of a component. Modern CNC lathes can turn components more accurately to size than they can be ground and with a better surface finish. Save money by specifying induction hardening.

5, Some components require some areas to remain soft after heat treatment. This can only be achieved in a furnace by stopping off the component. The stopping off technique alone is usually more expensive than the cost of the induction hardening process and the induction process only hardens the portions required to be hard.

Q: How to choose a suitable induction heater?

A: Induction heaters have many different modles with different power and frequency.

1, The higher power, the faster of the heating speed. so if you want to heat fast then you'd better choose a high power induction heater.

2, The higher frequency, the lower of the heating layer. So for some surface hardening, we suggest use a higher frequency heater, for some entire heating (like forging and melting) we suggest to use low frequency heater.

3, If you are not sure of which model is suitable for your work, please ask our salesman for suggestion before you place an order.

Sincerely provide service for you!