Brand Name: YORK

Model Number: YIA Water-Cooled Single Stage Absorption Chiller

Place of Origin: China (Mainland)

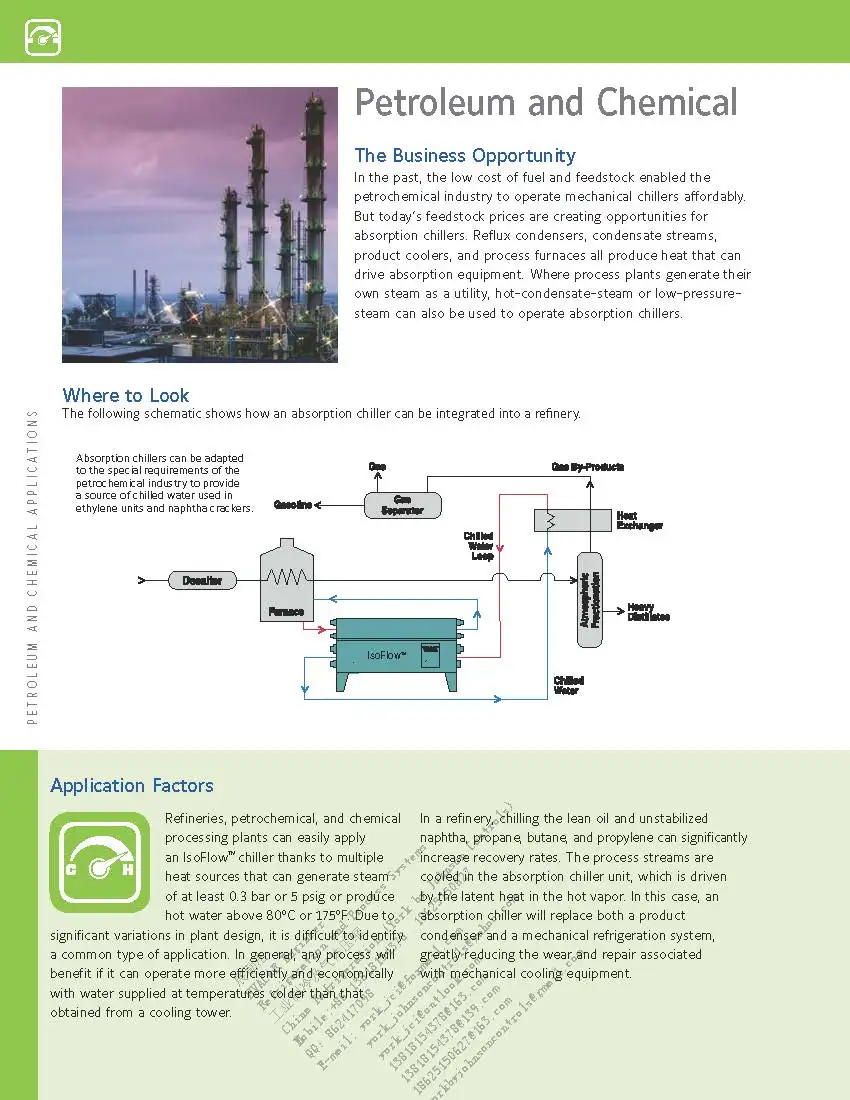

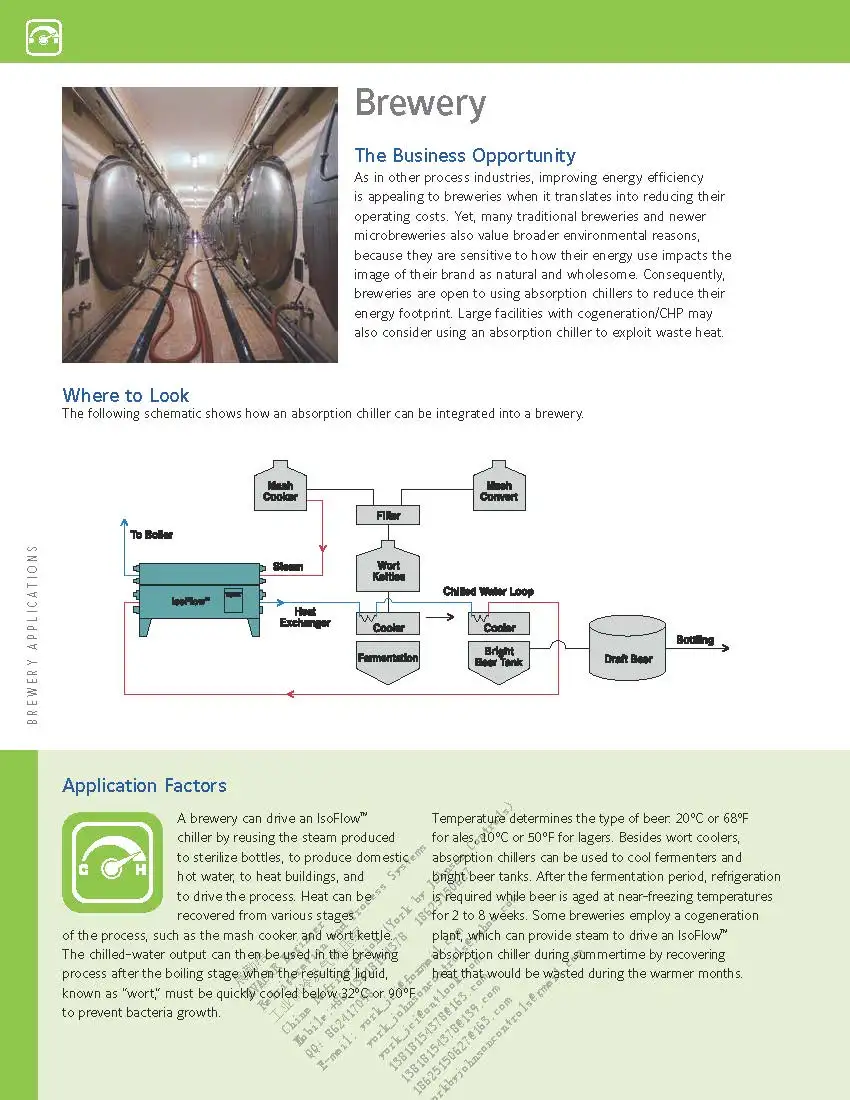

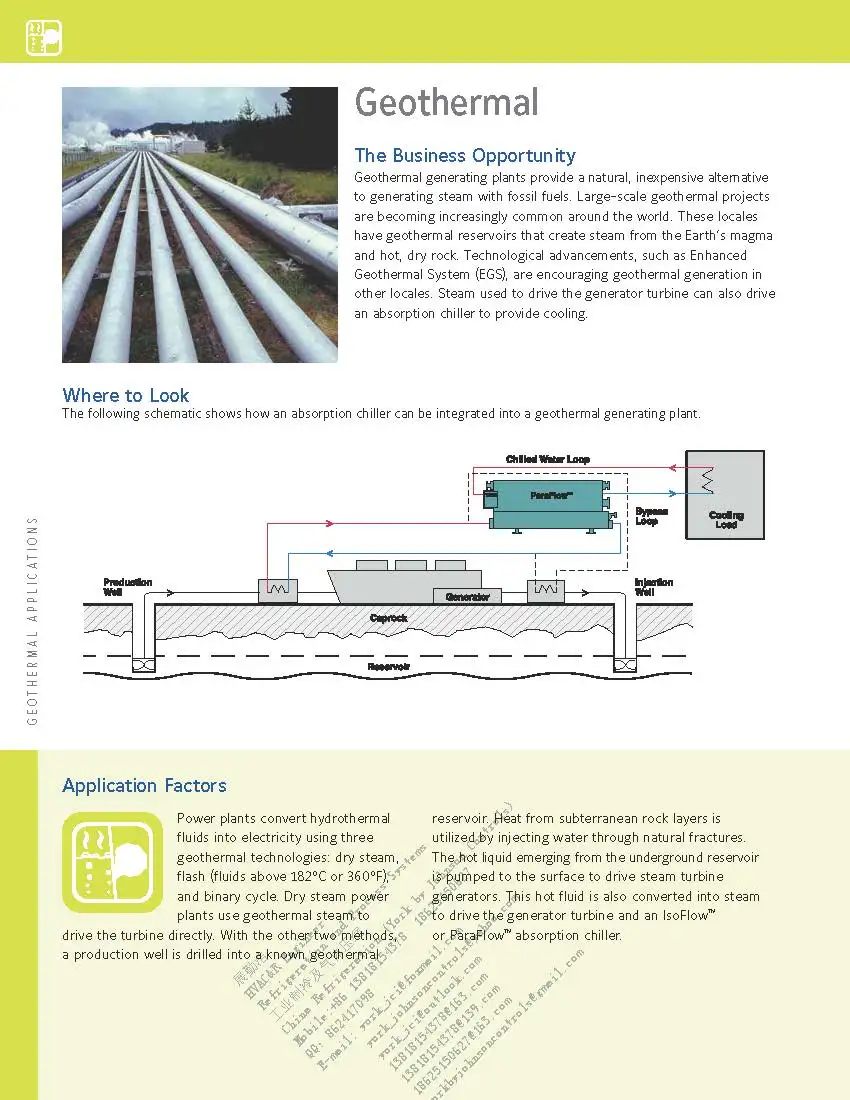

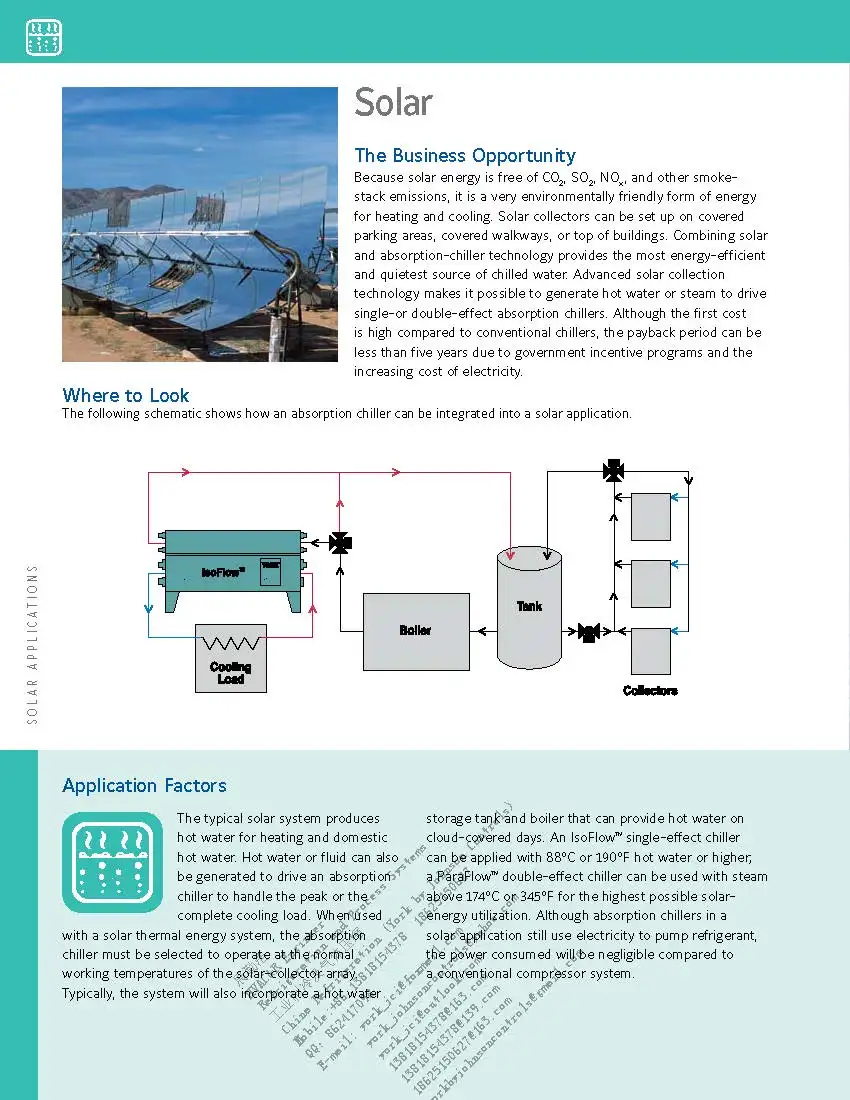

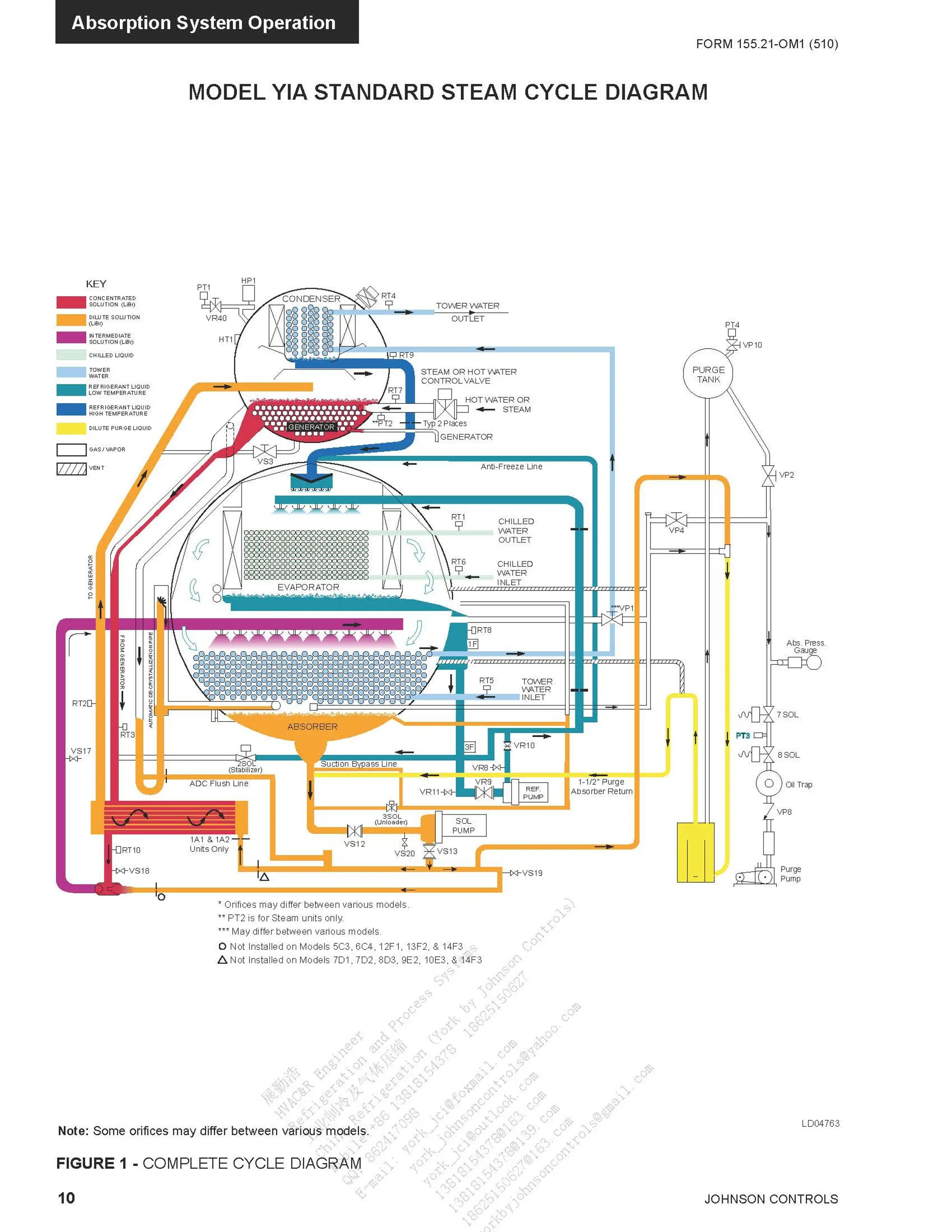

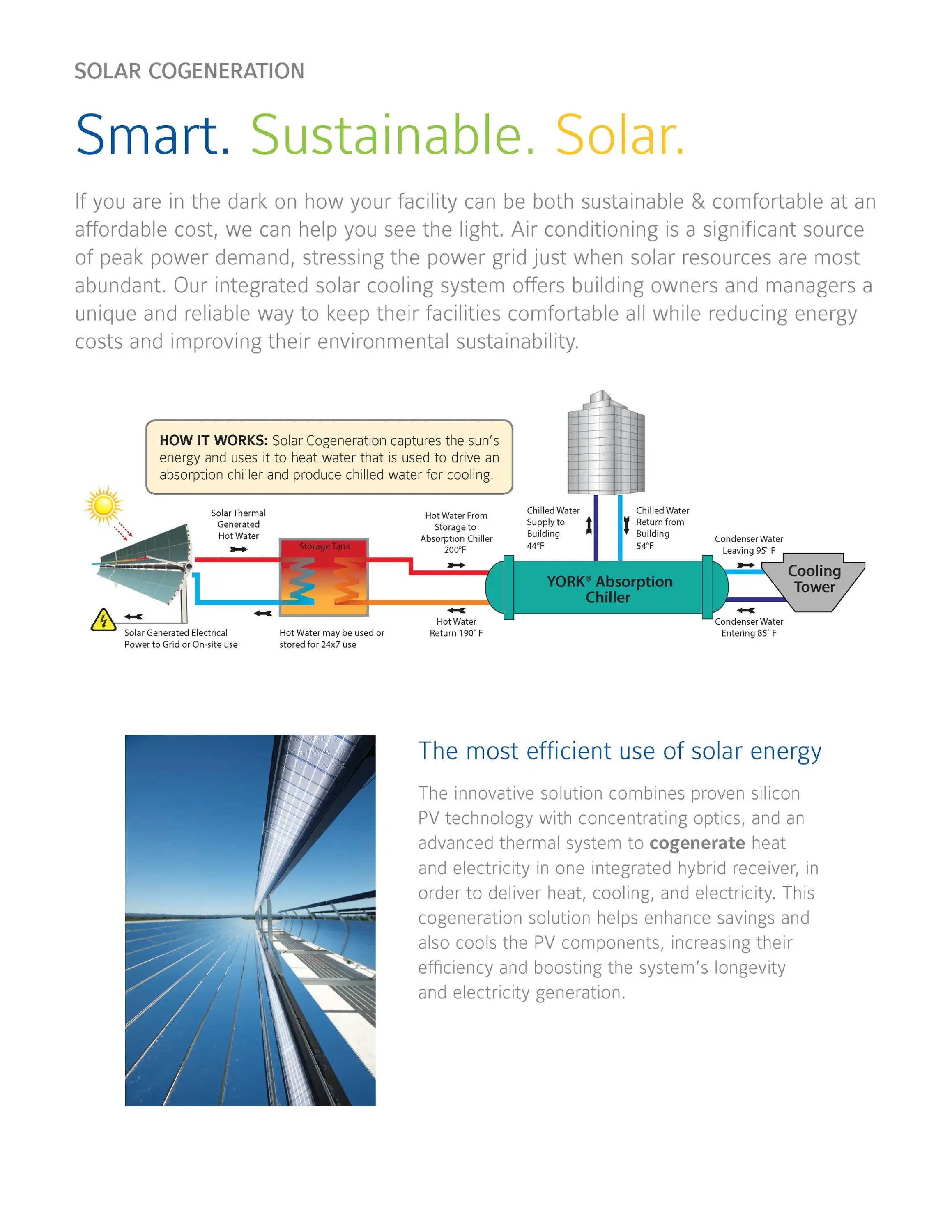

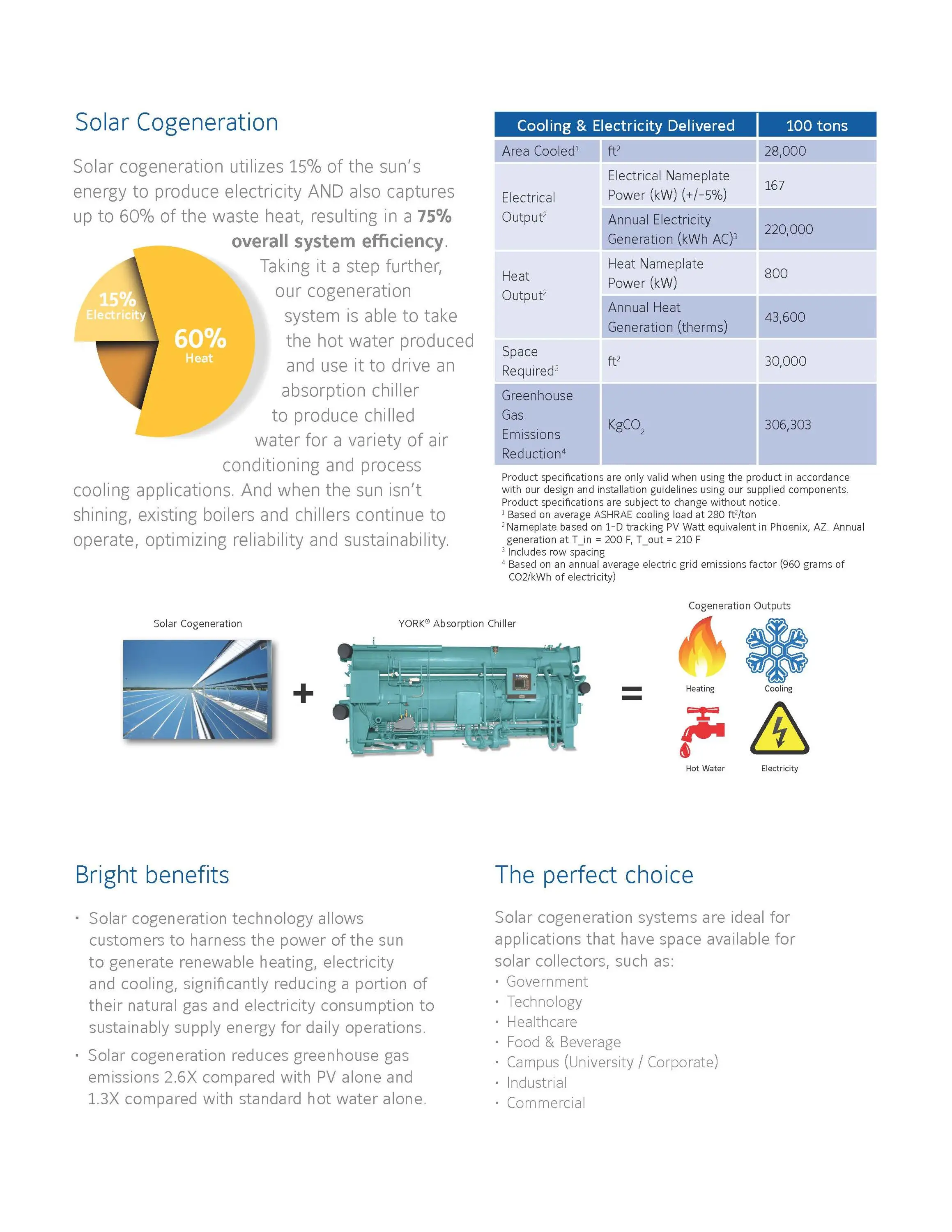

Reduce waste energy and get the efficient cooling you need with our YIA Absorption Chiller from YORK®. At Johnson Controls, we've engineered this single-stage absorption chiller to feature a rugged, industrial grade design with user-friendly microprocessor controls designed to increase reliability and enhance performance.

With the flexibility to capture waste hot water or steam, natural gas and more to produce efficient cooling and even solar cogeneration, the YIA Absorption Chiller is ideal for any application where waste energy is produced.

Absorption chillers using lithium bromide as an absorbent have

proven to be a cost-effective and an environmentally responsible

alternative to chillers using CFC (chlorofluorocarbon) refrigerants.

However, if not properly controlled, lithium bromide is corrosive.

Therefore, steps need to be taken to protect the machine against

premature component failure that can result in increased maintenance

costs, unproductive downtime and shortened machine life. What

follows is an explanation of the need for corrosion inhibitors,

and evaluation of alternatives and a demonstration of why

ADVAGuard® 750 is the superior alternative.

Get a head start on corrosion

Corrosion brought on by lithium bromide starts very early in

the operating life of the chiller. Therefore, a corrosion inhibitor

must be present in the solution prior to commissioning

(or start-up). In the absence of an inhibitor, the corrosion

generates hydrogen gas. This gas, unless purged, will

adversely affect chiller performance.

Generally speaking, corrosion inhibitors promote the formation

of an oxide film, magnetite. It is this stable oxide layer that helps

to minimize corrosion in the machine. Fortunately, the magnetite

film forms on the steel surfaces in the vessel during initial

operation of the unit.

Maintain protection throughout machine life

To ensure the stability of this film, proper inhibitor levels must

be maintained throughout the operating life of the machine.

Unstable oxide films can lead to an increase in corrosion rates,

resulting in decreased unit life and poor system performance

from excessive hydrogen generation. An unstable film can also

result in rapid inhibitor depletion causing contamination of the

lithium bromide solution. The contaminated solution will then

need to be filtered, adding to unit maintenance costs.

All corrosion inhibitors are not equal

Customers who have experience with absorbers can relate

to the importance of a corrosion inhibitor. But far too often,

this experience leads to the misconception that all inhibitors

offer the same level of protection. Available corrosion inhibitors,

while effective in certain areas, can't offer complete protection,

for instance:

• Molybdate — currently the most commonly used inhibitor —

suffers from limited solubility in the lithium bromide solution,

making it difficult to maintain a stable concentration of

molybdate in the solution.

• Chromate inhibitors contain hazardous chromium compounds,

which are potential carcinogens.

• Nitrate inhibitors typically generate ammonia, which may

result in destructive stress cracking of the copper and copper

alloy tubes. Ammonia also acts as non-condensable gas,

which affects chiller performance.

Why ADVAGuard 750 is unsurpassed

Where other inhibitors fail, ADVAGuard 750, developed by the

lithium experts at FMC corporation, performs — time and again.

Available exclusively from Johnson Controls, it is an inorganic

corrosion inhibitor that provides superior corrosion protection.

ADVAGuard 750 is effective over a wide range of temperatures

as well, facilitating use in single-effect, double-effect and tripleeffect

machines that use lithium bromide as an absorbent.

Economic Analysis of

Hybrid Chiller Plants

About the Author

T

By Brian Smith

Brian Smith is a product manager for the

Engineered Systems group of York International,

York, Pa.

raditionally, chiller plants in large facilities consisted of constant-speed,

electric-drive centrifugal chillers because they were the least expensive

and most efficient option. Although natural gas was cheaper

than electricity on a $/Btu basis, the price difference wasn’t sufficient

to offset the efficiency and capital-cost differences between electric

and non-electric chillers.

In the past few years, the

metrics have changed. Today,

hybrid chiller plants using

multiple chillers and different

energy sources are being considered

in many applications.

What has changed?

A significant factor is the

new time-of-use rate structures

that electric utilities are implementing.

While these new rate

structures vary among utilities,

users generally pay a lower rate

when electricity demand is low

(off-peak periods) and a much

higher rate when demand is high (onpeak

periods).

For example, some utilities have

moved to real-time pricing (RTP), which

is a pricing schedule where rates are determined

a day or two in advance of their

use. RTP rates eliminate or reduce demand

charges. However, their presence

is felt in the peak pricing of electricity.

High on-peak prices are the primary

means for electricity producers to recoup

the cost of their peaking plants. With RTP,

the price of electricity fluctuates with

ated because they use multiple energy

sources. In markets where high on-peak

electricity rates exist and natural gas

prices are low, a combination of electric

and non-electric chillers may make the

most sense from a long-term economic

perspective.

This article tries to answer the question,

“How high must electricity

prices be to justify a hybrid

chiller plant?” In the following

economic analysis of hybrid

chiller plants, we first established

a baseline of relative

chiller efficiencies and capital

costs, according to data from

multiple manufacturers. Next,

we selected an industrial user

rate for natural gas, which we

held constant throughout the

analysis. Then, we varied the

peak price of electricity to test

the sensitivity of various chiller

combinations to progressively

higher on-peak electric prices. Finally,

we analyzed life-cycle costs, comparing

the operating cost savings to the

additional capital costs. From these calculations,

we drew some general conclusions

about hybrid chiller plants that

will help engineers evaluate their feasibility

from a long-term economic perspective.

market demand and the weather, because

high demand for electricity and warm

weather tend to be synchronous.

Thus, owners, managers, and designers

of large facilities exposed to these

rate structures are recognizing that the

biggest opportunity to reduce energy

costs is to reduce the high-cost, on-peak

use of electricity by their HVAC systems.

In non-residential facilities, chillers are

one of the largest energy users, so they

are receiving a lot of attention.

Hybrid chiller-plants are being

York (Wuxi) air Conditioning and Refrigeration Co. Ltd, Located in Wuxi National High-tech Industrial Park, Jiangsu province, China. Covers an area of 60000 square meters, of which the heavy machine factory building takes up 14,000 square meters. At present, the company has about 500 staffs, in the field of large-size units. York Wuxi is the largest manufacturer in Asia –pacific region with an annual output of more than 3600 sets. Its products not only top on market share in China, but also see tremendous growth in export in recent years.

York Wuxi has six production lines in total, of which five are automated lines, including one air-cooled screw production line, one large-size water-cooled screw unit production line, one small-size water-cooled screw unit production line, and two centrifugal unit production line. All production line adapt the DFT technology, being the first in the industry. The entire work process is compact and rational. With the efficient management method (such as four-color light), these lines have become the most compact, most efficient and most advanced production line in the industry.

York Wuxi is equipped with globally advance equipment in every step of its production process, including:

Most advanced plasma digital cutter which can be used under water

Efficient digital plate bending machine with a roll length up to 4.8 meters

LINCO DC submerged arc welder imported from USA which is the most advanced equipment in the world.

Most advanced digital drill press in the industry.

Four large-sized chiller comprehensive performance test branches, (test capacity per set up to 2000 cold tons, for 10KV high voltage tests and frequency conversion tests), presenting the most advanced level in China.

YORK (CHINA) introduced the Performance Excellence Mode since the beginning of its operation. This mode adopted by most world-class enterprises focuses on the customers. It learns, meets and exceeds the customers’ needs and serves society through its human-oriented strategy and corporate culture. Based on the effective QEHS management system and advanced management tools (e.g. six-sigma).YORK (CHINA) consolidates its leading status in the industry.

1. YORK RESEARCH AND DEVELOPMENT

In December 2004, to provide high-quality and competitive air conditioning products and refrigeration equipments to the Asia-Pacific region and on the parts of the world, YORK set up the YORK Asia Pacific research and development center in

Wuxi.

The center has the most advanced software systems, highly qualified professionals, and various test equipments and systems. The air-cooled test bench, unique in China and the largest in the

Asia-Pacific region, which has complete spring base for the equipment vibration test, can lower the noise to 20db by means of muffle devices. It also can carry out the working environment temperature simulation test by changing the indoor temperature via air conditioning and refrigeration system.

Since its establishment, the R&D center is dedicated to development efficient, energy saving, environment friendly products with independent intellectual property and unique technology and to the research of thermal conductivity, noise vibration and reliability to meet the needs of refrigeration &air conditioning in China and even the entire Asia-Pacific region. At the same time, the R&D center is also working closely with YORK international’s R&D division to develop money advanced products that can meet the global needs, In fact, innovation and renovation of many core technologies are happening in the Wuxi center.

2. YORK SEVICES INTRODUCTION

York Air Conditioning & Refrigeration Service Centre was established in 1993 in Shanghai. The Service Centre is now having stations in Beijing, Nanjing, Guangzhou, Xiamen, Wuhan and Shenzhen, and service representatives in Shantou, Changsha, Chengdu, Jinan, Dalian, Harbin and Hangzhou, and so on. Using our established service center networks throughout China, we are able to provide full after-sales services to all our customers in China.

At the same time, the service center is having a bonded spare parts warehouse in Shanghai. The spare parts warehouse will serve the spare part needs for our customers with minimum delivery time.

Qinhao Zhan

HVAC&R Engineer

Refrigeration and Process Systems

China Refrigeration (York by Johnson Controls)

Mobile:+86 13818154378 18625150627

QQ: 826554493

862417098

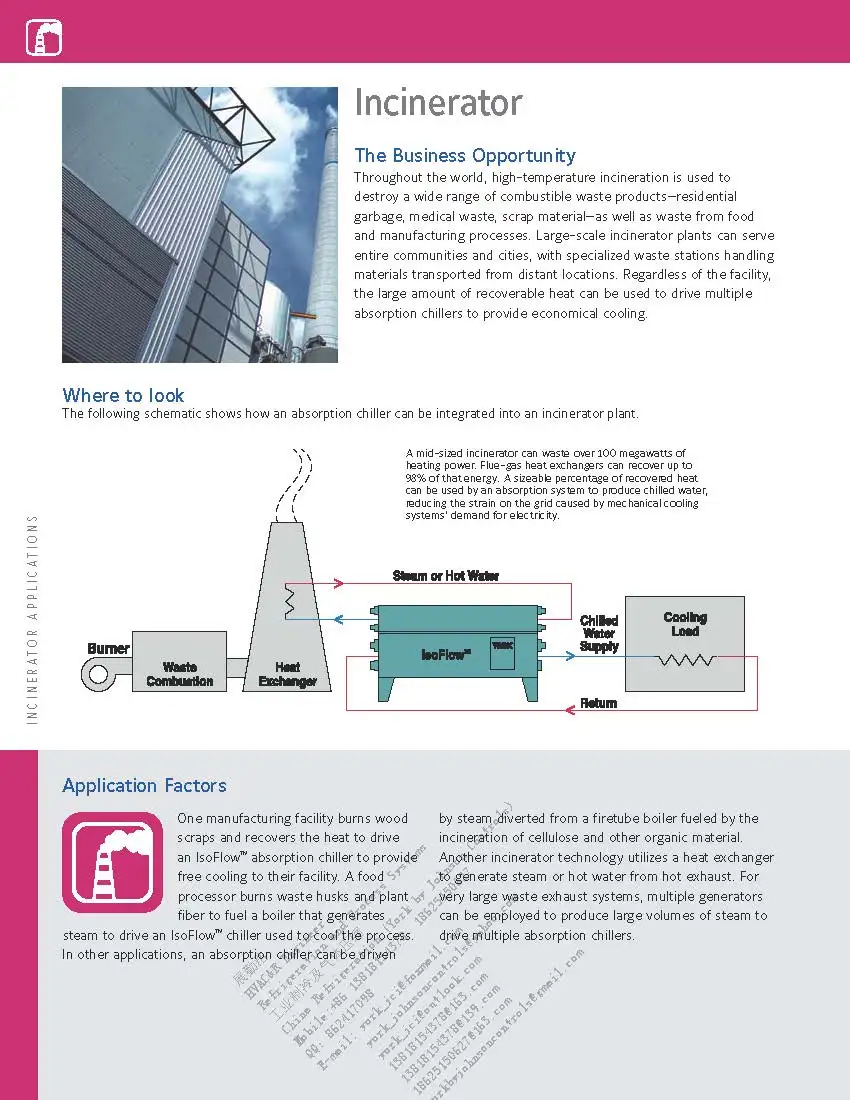

Johnson Controls York Industrial Refrigeration - Shanghai Jiusui-Ref Systems Engineering Co., Ltd.: harsh industrial environments breakthrough in industrial refrigeration + accuracy + = large cooling load fluctuations York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd tailor-made industrial refrigeration systems!

Provide personalized solutions for five major areas! Can be mainly used in petroleum, petrochemical process; chemical technology; synthetic rubber technology; fertilizer production process and chemical fiber textile technology. A number of other applications to meet different needs!

In addition to the above five major areas, York- Shanghai Jiusui-Ref Systems Engineering Co., Ltd Industrial refrigeration approved for use in air separation plants, liquefaction plants, carbon dioxide recovery systems, pharmaceutical industry, tobacco industry and steel plants, power plants, electronics factories and other process cooling And refrigeration systems.

York Shanghai Jiusui-Ref Systems Engineering Co., Ltd is located in the petrochemical industry, whether it is upstream natural gas compression, midstream liquefied natural gas storage, transshipment, or downstream air separation, liquefaction unit, as long as the compression-related York- Shanghai Jiusui-Ref Systems Engineering Co., Ltd are involved!

Advanced control system + energy efficient refrigeration equipment + overall solution = York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd a full range of food refrigeration business!

Food processing + large cold storage + poultry slaughter + beer drinks + dairy products + aquatic fisheries + small logistics distribution center, etc. = York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd food refrigeration business coverage!

P.K. "China cold village" -58 ℃ low temperature! (-28 ℃ ~ 15 ℃), and even tuna low-temperature cold storage (-55 ℃ ~ -60 ℃), York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd food refrigeration business can be, but also the production of cold storage, Complete turnkey project. Diverse demand one stop to meet! Supporting cold storage products with cooling water system to meet the dairy products, beer and other light industry diverse needs. Sea and land to eat to ensure the quality of fish and shrimp! Provide on board and onshore fish and shrimp processing supporting the cooling and quick-frozen products, stable and reliable products to York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd frozen food business filled with full.

Hot summer experience! Not only in the game-type ice rink and entertainment ice rink unique advantages, but also for the automatic ice-making plant and ice cream factory to provide frozen solution.