Brand Name: YORK

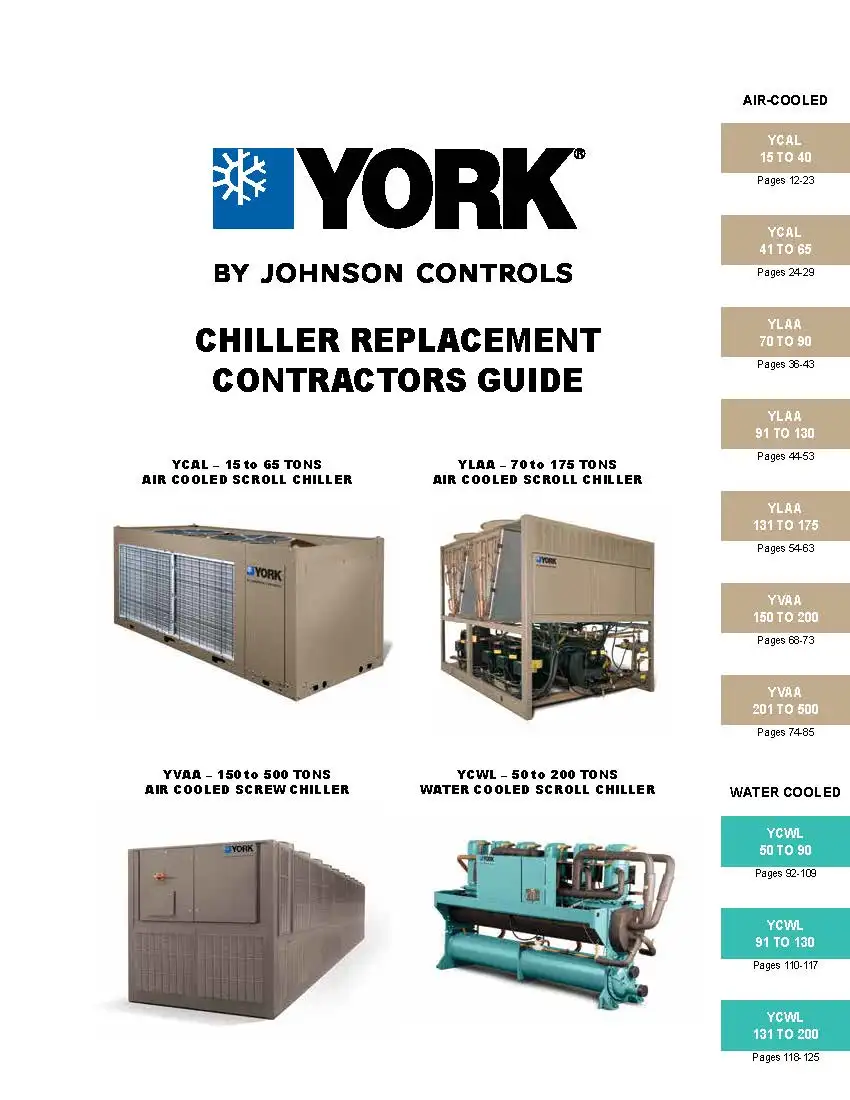

Model Number: YCAL

Place of Origin: China (Mainland)

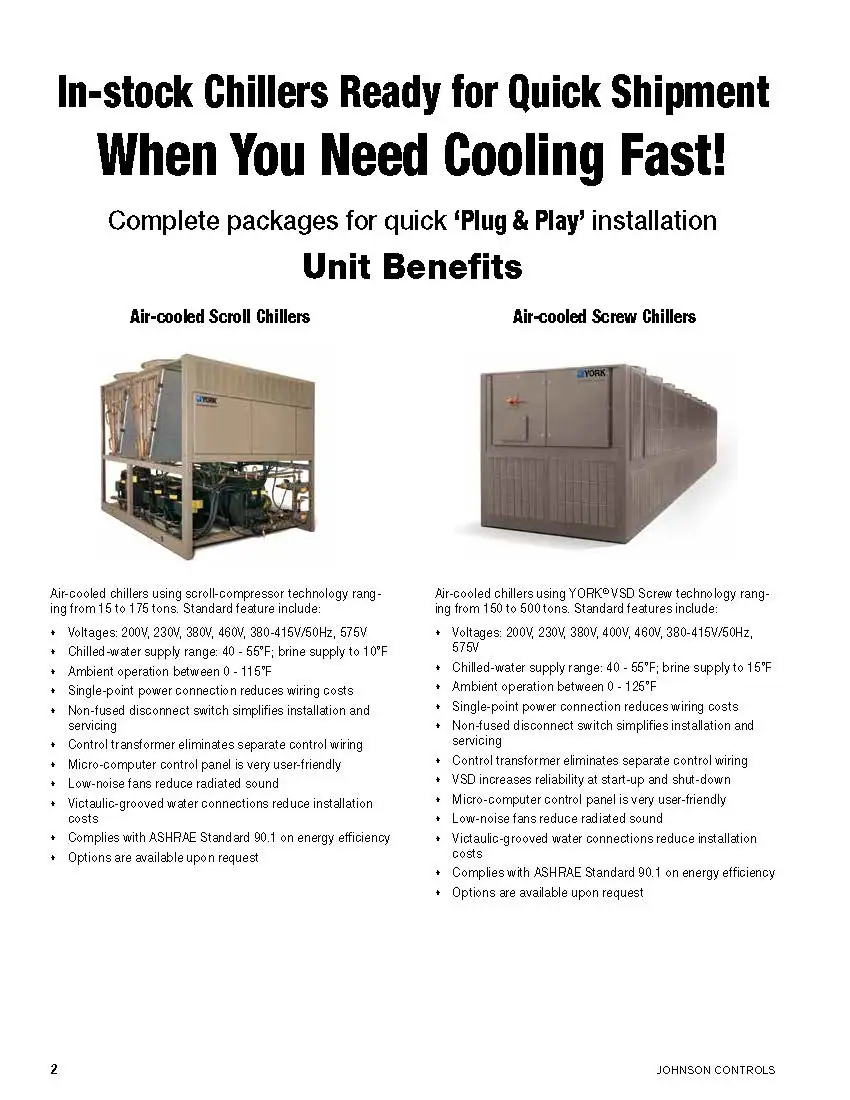

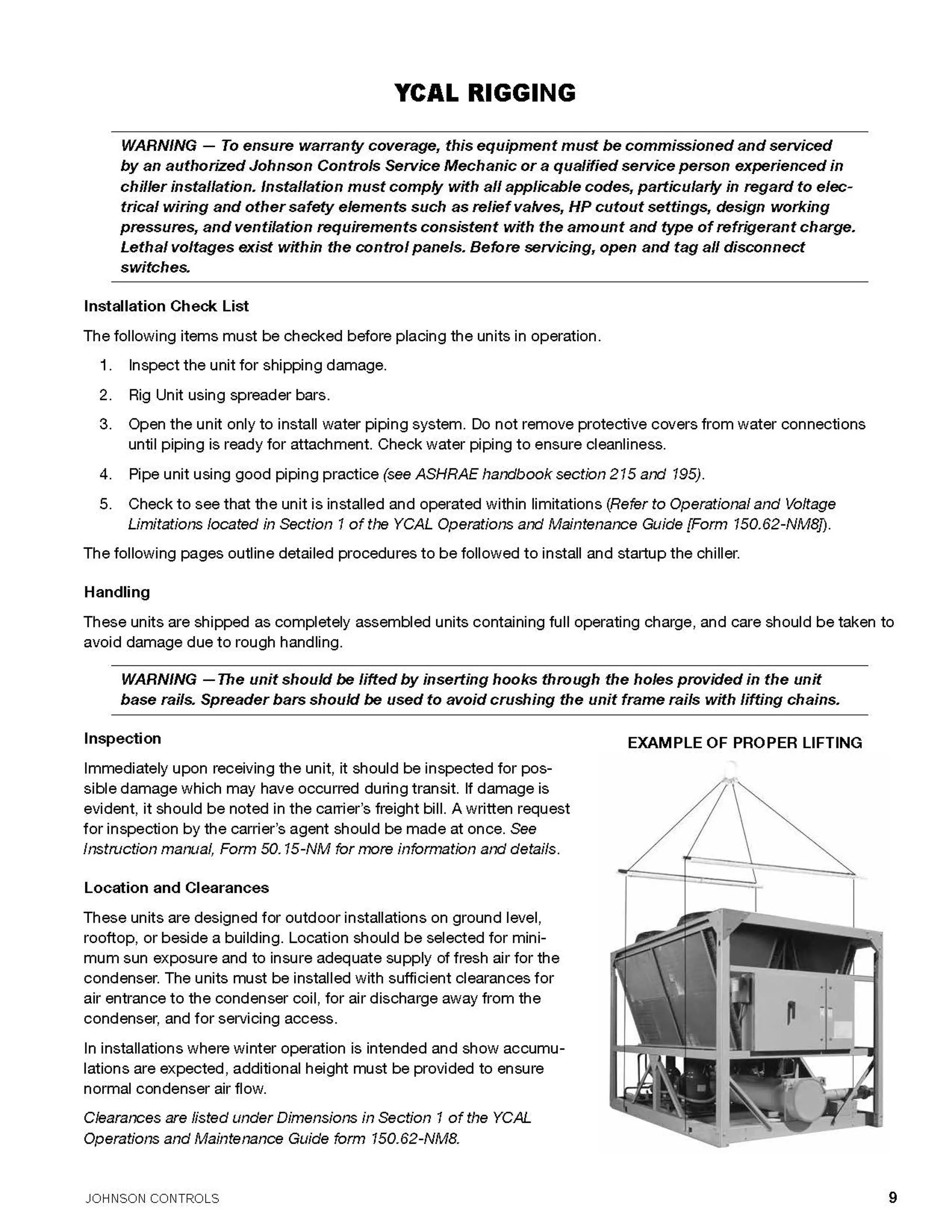

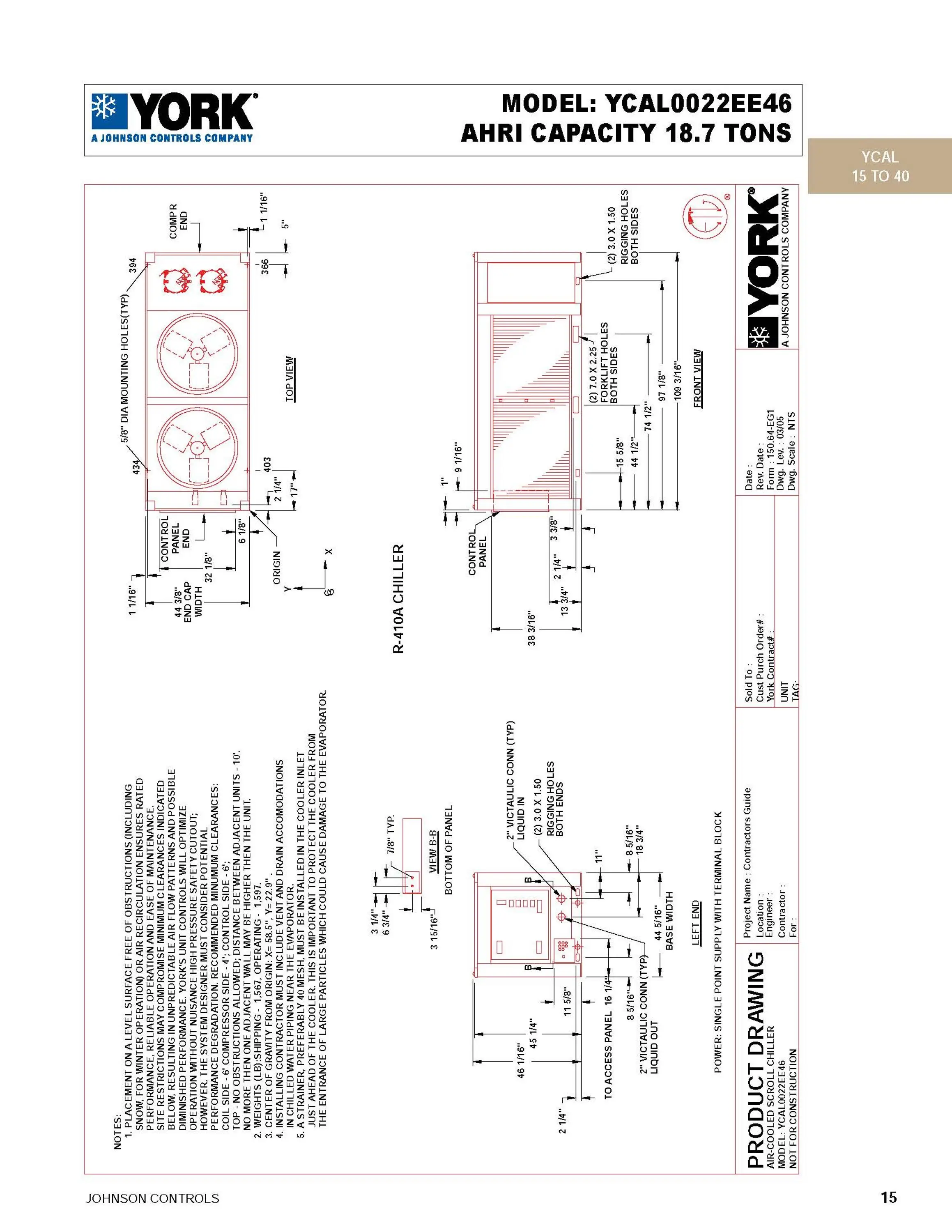

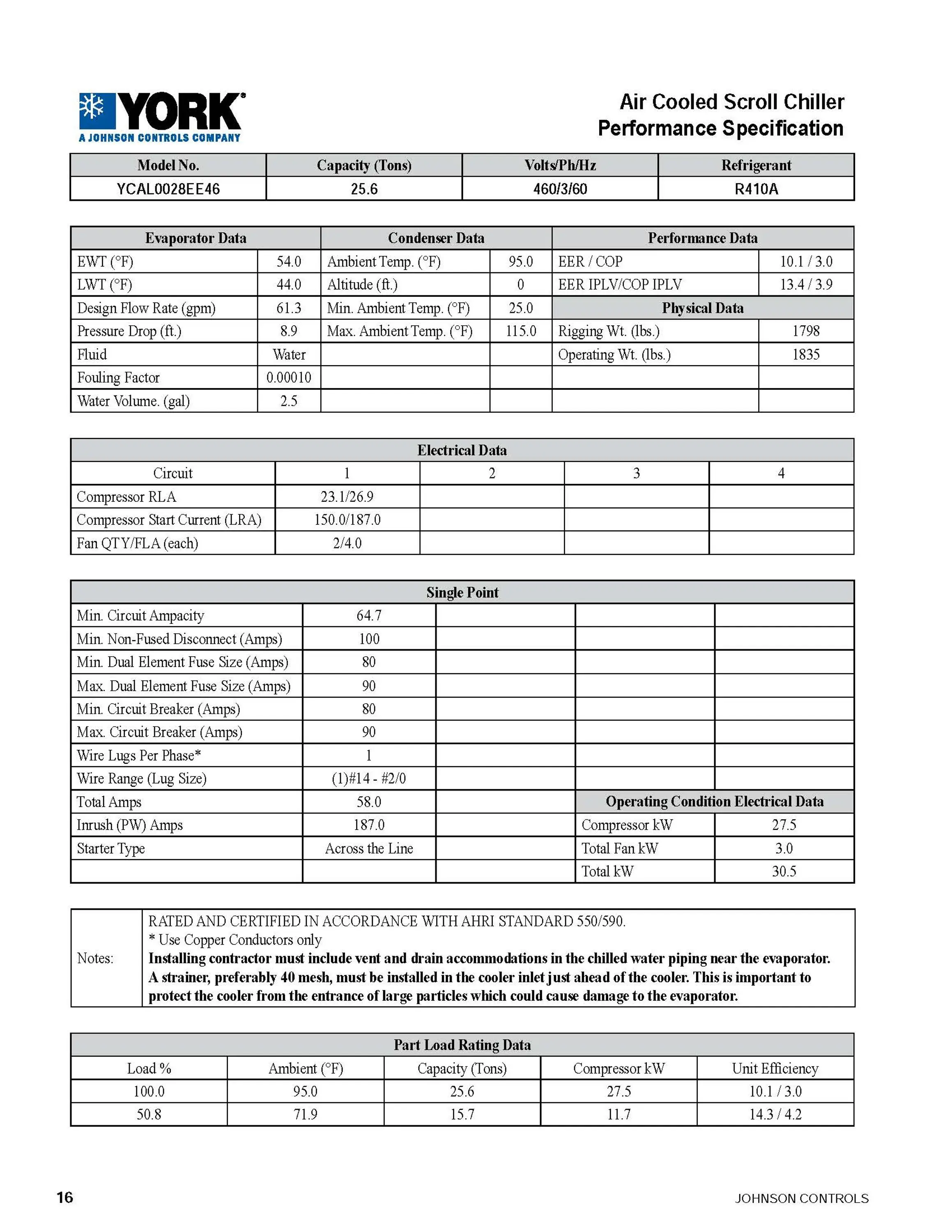

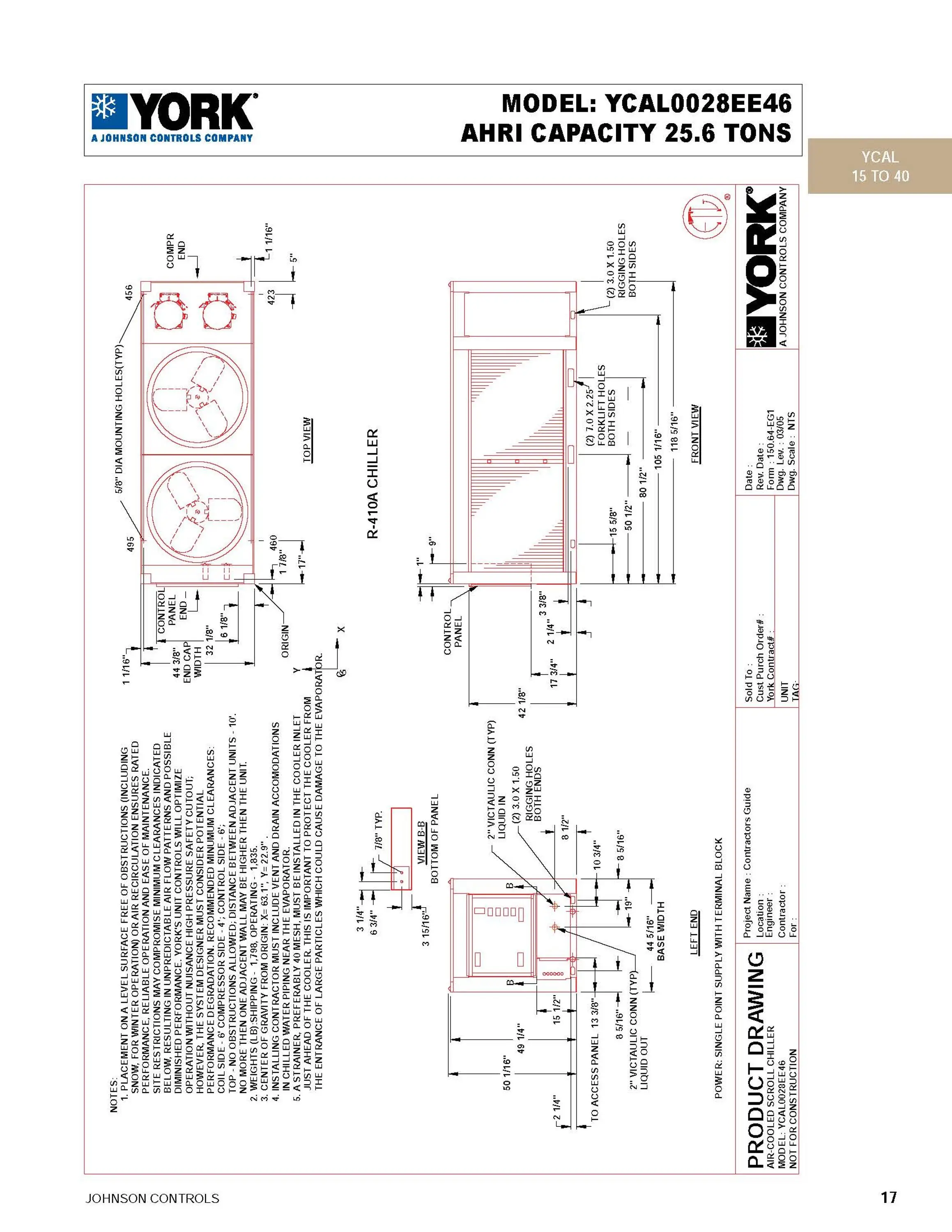

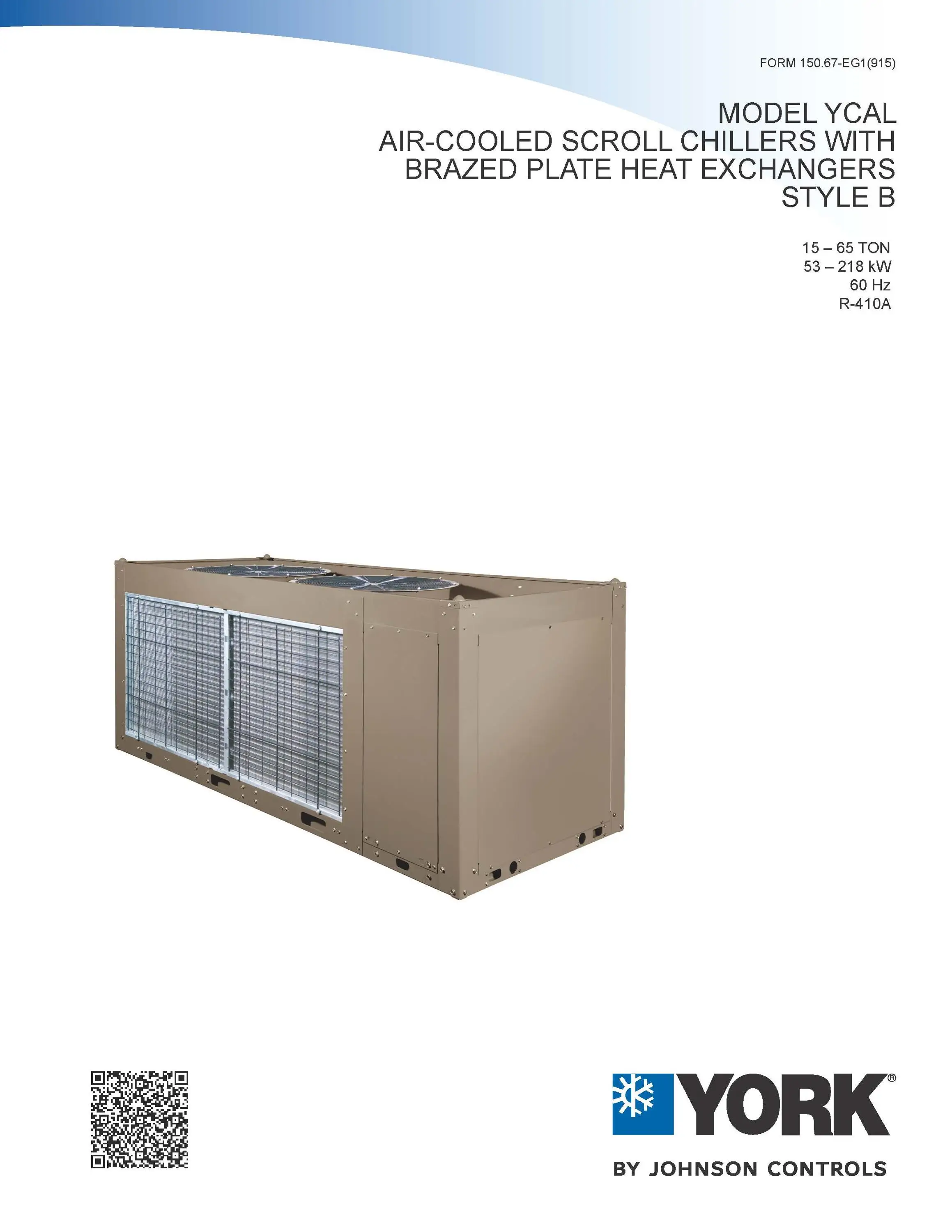

At YORK® by Johnson Controls, we help you minimize the total cost of ownership for your air conditioning application with our YCAL Air-Cooled Scroll Chiller. This air-cooled chiller uses scroll compressor technology and is a reliable, completely self-contained unit that is designed for easy, low-cost outdoor installation.

Our YCAL Air-Cooled Chillers feature a single-point power connection for reduced wiring costs, industry leading environmentally friendly design, high energy efficiency, and a light, small unit to maximize your usable space.

York (Wuxi) air Conditioning and Refrigeration Co. Ltd, Located in Wuxi National High-tech Industrial Park, Jiangsu province, China. Covers an area of 60000 square meters, of which the heavy machine factory building takes up 14,000 square meters. At present, the company has about 500 staffs, in the field of large-size units. York Wuxi is the largest manufacturer in Asia –pacific region with an annual output of more than 3600 sets. Its products not only top on market share in China, but also see tremendous growth in export in recent years.

York Wuxi has six production lines in total, of which five are automated lines, including one air-cooled screw production line, one large-size water-cooled screw unit production line, one small-size water-cooled screw unit production line, and two centrifugal unit production line. All production line adapt the DFT technology, being the first in the industry. The entire work process is compact and rational. With the efficient management method (such as four-color light), these lines have become the most compact, most efficient and most advanced production line in the industry.

York Wuxi is equipped with globally advance equipment in every step of its production process, including:

Most advanced plasma digital cutter which can be used under water

Efficient digital plate bending machine with a roll length up to 4.8 meters

LINCO DC submerged arc welder imported from USA which is the most advanced equipment in the world.

Most advanced digital drill press in the industry.

Four large-sized chiller comprehensive performance test branches, (test capacity per set up to 2000 cold tons, for 10KV high voltage tests and frequency conversion tests), presenting the most advanced level in China.

YORK (CHINA) introduced the Performance Excellence Mode since the beginning of its operation. This mode adopted by most world-class enterprises focuses on the customers. It learns, meets and exceeds the customers’ needs and serves society through its human-oriented strategy and corporate culture. Based on the effective QEHS management system and advanced management tools (e.g. six-sigma).YORK (CHINA) consolidates its leading status in the industry.

1. YORK RESEARCH AND DEVELOPMENT

In December 2004, to provide high-quality and competitive air conditioning products and refrigeration equipments to the Asia-Pacific region and on the parts of the world, YORK set up the YORK Asia Pacific research and development center in

Wuxi.

The center has the most advanced software systems, highly qualified professionals, and various test equipments and systems. The air-cooled test bench, unique in China and the largest in the

Asia-Pacific region, which has complete spring base for the equipment vibration test, can lower the noise to 20db by means of muffle devices. It also can carry out the working environment temperature simulation test by changing the indoor temperature via air conditioning and refrigeration system.

Since its establishment, the R&D center is dedicated to development efficient, energy saving, environment friendly products with independent intellectual property and unique technology and to the research of thermal conductivity, noise vibration and reliability to meet the needs of refrigeration &air conditioning in China and even the entire Asia-Pacific region. At the same time, the R&D center is also working closely with YORK international’s R&D division to develop money advanced products that can meet the global needs, In fact, innovation and renovation of many core technologies are happening in the Wuxi center.

2. YORK SEVICES INTRODUCTION

York Air Conditioning & Refrigeration Service Centre was established in 1993 in Shanghai. The Service Centre is now having stations in Beijing, Nanjing, Guangzhou, Xiamen, Wuhan and Shenzhen, and service representatives in Shantou, Changsha, Chengdu, Jinan, Dalian, Harbin and Hangzhou, and so on. Using our established service center networks throughout China, we are able to provide full after-sales services to all our customers in China.

At the same time, the service center is having a bonded spare parts warehouse in Shanghai. The spare parts warehouse will serve the spare part needs for our customers with minimum delivery time.

Qinhao Zhan

HVAC&R Engineer

Refrigeration and Process Systems

China Refrigeration (York by Johnson Controls)

Mobile:+86 13818154378 18625150627

QQ: 826554493

862417098

Johnson Controls York Industrial Refrigeration - Shanghai Jiusui-Ref Systems Engineering Co., Ltd.: harsh industrial environments breakthrough in industrial refrigeration + accuracy + = large cooling load fluctuations York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd tailor-made industrial refrigeration systems!

Provide personalized solutions for five major areas! Can be mainly used in petroleum, petrochemical process; chemical technology; synthetic rubber technology; fertilizer production process and chemical fiber textile technology. A number of other applications to meet different needs!

In addition to the above five major areas, York- Shanghai Jiusui-Ref Systems Engineering Co., Ltd Industrial refrigeration approved for use in air separation plants, liquefaction plants, carbon dioxide recovery systems, pharmaceutical industry, tobacco industry and steel plants, power plants, electronics factories and other process cooling And refrigeration systems.

York Shanghai Jiusui-Ref Systems Engineering Co., Ltd is located in the petrochemical industry, whether it is upstream natural gas compression, midstream liquefied natural gas storage, transshipment, or downstream air separation, liquefaction unit, as long as the compression-related York- Shanghai Jiusui-Ref Systems Engineering Co., Ltd are involved!

Advanced control system + energy efficient refrigeration equipment + overall solution = York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd a full range of food refrigeration business!

Food processing + large cold storage + poultry slaughter + beer drinks + dairy products + aquatic fisheries + small logistics distribution center, etc. = York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd food refrigeration business coverage!

P.K. "China cold village" -58 ℃ low temperature! (-28 ℃ ~ 15 ℃), and even tuna low-temperature cold storage (-55 ℃ ~ -60 ℃), York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd food refrigeration business can be, but also the production of cold storage, Complete turnkey project. Diverse demand one stop to meet! Supporting cold storage products with cooling water system to meet the dairy products, beer and other light industry diverse needs. Sea and land to eat to ensure the quality of fish and shrimp! Provide on board and onshore fish and shrimp processing supporting the cooling and quick-frozen products, stable and reliable products to York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd frozen food business filled with full.

Hot summer experience! Not only in the game-type ice rink and entertainment ice rink unique advantages, but also for the automatic ice-making plant and ice cream factory to provide frozen solution.