Brand Name: YORK

Model Number: YST VF VD J4 - KD71750090 - 14 - 0.6 - 33192C - F S

Place of Origin: Jiangsu, China (Mainland)

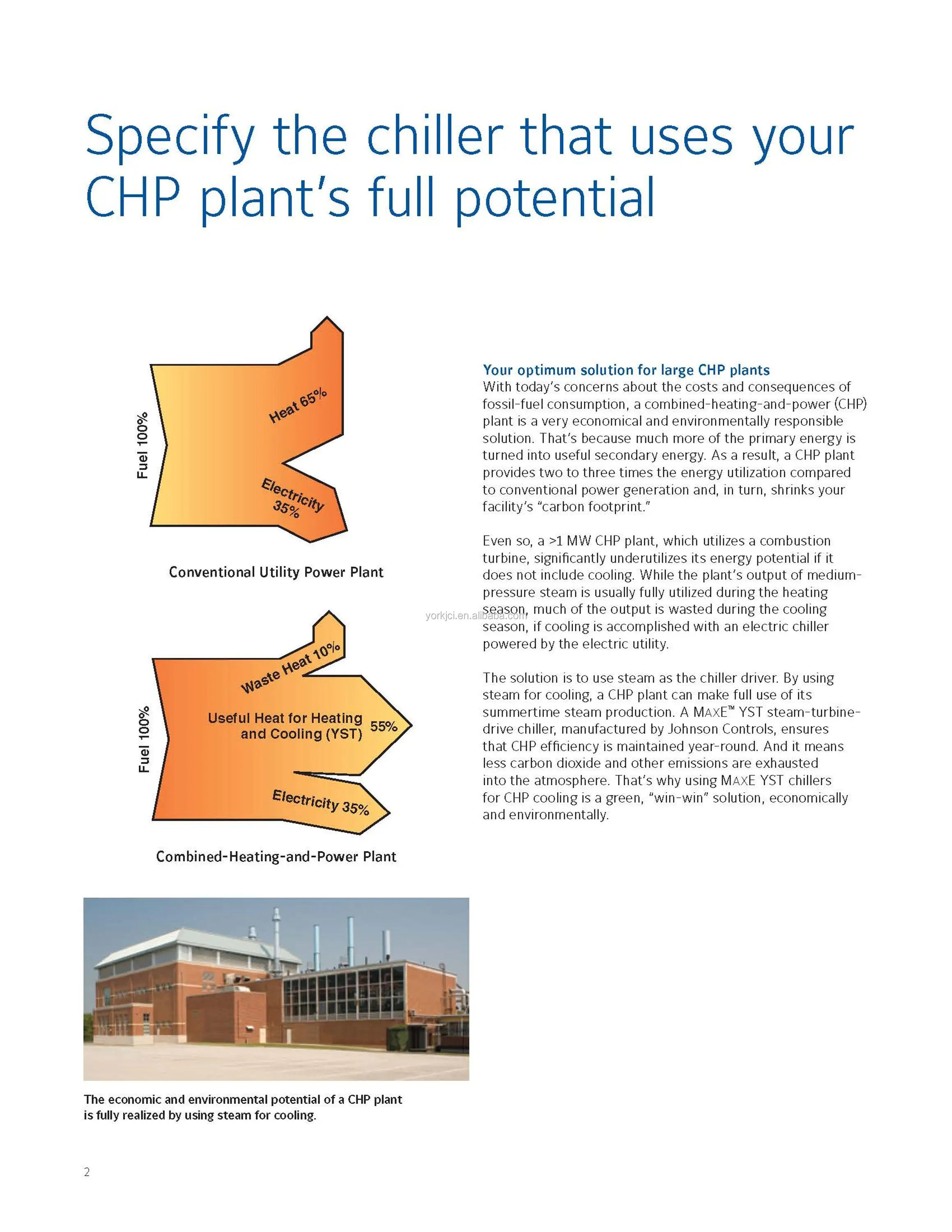

The perfect choice for large combined-heating-and-power (CHP) plants, our YORK® YST Steam Chiller ensures that CHP efficiency is maintained year-round, which means less carbon dioxide and other emissions are exhausted into the atmosphere, making it the truly green solution.

At Johnson Controls, we've manufactured the YST Steam Chiller to use your CHP plant's full potential. Featuring compact packaging and the flexibility to fit any job, our steam turbine chiller is easy to own with sophisticated controls specifically designed for steam.

A

By ROY S. HUBBARD

Johnson Controls Inc.

York, Pa.

As the cost of energy continues to rise, it behooves

chiller-plant owners and designers to consider the

energy impacts of virtually everything under their control,

including chilled-water piping.

This article will discuss the energy consumption of

the three basic configurations of chilled-water piping

currently in use: constant primary flow (CPF), constant

primary flow/variable secondary flow (P/S), and variable

primary flow (VPF). Also, it will discuss the attributes

of equipment-room space, installed cost, and control

complexity.

Constant Primary Flow

Operation. Figure 1 illustrates a

CPF arrangement at 100-percent

system load. The most basic of the

three configurations, this is used

in many smaller plants. As the name

implies, the chilled-water (CHW)

pumps are constant speed, and water

flow varies only when a chiller and

its pump are cycled off for capacity

purposes.

Throughout this article, the following

formula will be used to analyze

how systems operate:

Load = Flow × Delta-T

where:

Delta-T = chilled-water-temperature range

In a CPF configuration, load changes are reflected

by changing delta-T. Typically, a three-way valve is

placed on the discharge of each coil. The valve’s job is

to maintain the set-point temperature of the air leaving

the coil. If the temperature of the air ventures above

or below its set point, the valve modulates the amount

of chilled water flowing through the coil, with excess

water bypassing the coil. This modulates the temperature

of the chilled water within the coil in accordance with the

formula above; coil capacity is adjusted until leaving-air

temperature once again is at its set point. Throughout

this process, operating chillers experience (roughly)

constant water flow.

Attributes. CPF designs have several advantages:

• Equipment-room space is minimized because there

is only one set of chilled-water pumps.

• Installed cost is low because constant-speed pumps

20 HPAC Engineering November 2011

Energy Impacts of

Chilled-Water-Piping

Configuration

Senior marketing manager for Johnson Controls Inc., Roy S. Hubbard has more than 30 years of experience in sales, marketing,

and applications, with particular focus on chilled-water systems. He is the architect of YORKcalc, Johnson Controls’ operating-cost

software for chiller plants. He has a bachelor’s degree in engineering from the United States Military Academy at West Point. He

team-powered cooling is a proven technology that offers an often-

overlooked alternative to electric cooling. Although this technology

has advanced significantly in recent years, it has received far

less attention than the predominant alternative — gas-powered cooling.

To better understand steam-powered cooling, this article presents

some its basic precepts and compares the most common types of

chillers for large-capacity plants.

ciency. In the last few years, high demand

charges and real-time pricing (RTP) of

electricity have provided a strong incentive

to manage electrical loads, especially

peak usage. Since peak usage generally

coincides with peak demand for air conditioning,

HVAC designers are considering

how to apply non-electric chillers to

reduce consumption of on-peak, highcost

electricity.

Choices of electric and steam chillers

are summarized in Table 1, which compares

overall efficiency (integrated partload

value [IPLV]) and capital cost.

Because we are comparing chillers powered

by different energy sources, the IPLVs

are stated as coefficient-of-performance

(COP) values. All the figures are based

on industry averages.

As Table 1 indicates, all of the steam

chillers carry a higher capital cost than

the electric chillers, as well as lower

IPLVs. So, when would it make sense to

use a steam chiller?

Energy Costs

The simple answer is this: if the cost of

electricity is sufficiently high relative to

the cost of steam, a steam chiller could

offer a lower life-cycle cost, despite its

higher capital cost and lower IPLV. Such

About the Author

Ian Spanswick is the product manager of the

Applied Chiller Group at York International Corp.,

York, Pa.

By Ian Spanswick, Member ASHRAE

Comparing Electric & Steam Chillers

Traditionally, chiller plants in large facilities

consist of electric centrifugal

chillers because they have comparatively

low capital cost and high effi-a scenario is not infrequent. As noted, demand charges — possibly

coupled with ratcheted rates — or an RTP rate structure

will result in high electricity costs. Conversely, low-cost steam

could be one of the outputs of an on-site power generation

plant, which also may have been installed as a means of lowering

peak demand.

All chiller energy sources have seen rising costs, as well as

questions about the stability of supply in some regions. This is

leading many engineers to evaluate combinations of electric

and non-electric chillers to capture the most advantageous

energy pricing, and provide a hedge against future uncertainty

with energy prices and supplies.

Hybrid Chiller Plants

Depending on local energy costs and rate structures, a combination

of electric and non-electric chillers (i.e., a hybrid chiller

plant) can provide lowest life-cycle cost.1 Of course, no two

chiller plants are identical, nor are their energy costs, so determining

the optimum chiller combination and best operating

strategy involves complex calculations. Fortunately, cost analysis

software programs can analyze multiple variables quickly

and help narrow equipment selections. These programs can

perform a sensitivity analysis to show the effect of fluctuating

energy costs and help determine, for example, the crossover

points to switch from electric chillers to steam chillers.

Steam Supplies

This article intentionally omits a detailed discussion of

single-stage absorption chillers, which are powered by lowpressure

steam (or hot water). This chiller technology is stable

and best suited to heat-recovery applications rather than using

steam as a primary energy source. Instead, the focus here is on

chillers applied in medium-pressure steam systems, commonly

in the range of 100 to 200 psi (690 to 1380 kPa). These chillers

have higher capital costs, but offer better IPLVs than low-pressure

steam chillers. In addition, this technology has been improved

so that medium-pressure steam chillers are easier to

install and operate than in the past.

Medium-pressure steam typically is provided in one of three

ways:

1. A utility steam system, found in certain metropolitan areas

(e.g., New York, Philadelphia, or Minneapolis/St. Paul);

2. A non-utility steam plant that serves its owner’s own distributed

system, usually including cogeneration of electricity

via gas turbine, with heat from the gas turbine exhaust used to

produce steam as an integral part of the cycle efficiency (found

in large institutional applications, e.g., college campuses); and

3. A boiler that is used for power generation or process/heating

duties in a facility; or one that is dedicated solely to a

steam chiller.

Cogeneration systems and boilers often operate year-round

to meet site demand but function inefficiently when producing

steam at low loads in summer. In some cases, it is most

economical to maintain higher firing rates through the summer

and produce steam for cooling. Additional savings can

come from demand-side management strategies that avoid peak

electric rates, competitive rates for interruptible supplies, or

even from utility rebates. Industry organizations such as the

International District Energy Association advocate the economic

and environmental benefits of operating such district

steam heating/cooling systems.2

Medium-Pressure Steam Chillers

The two most common types of medium-pressure steam chillers

are two-stage absorption chillers and steam-turbine centrifugal

chillers. Basically, an absorption chiller uses a boiling

refrigerant (usually water) to extract heat from the chilled liquid,

and uses an absorbent solution (usually lithium bromide)

to regenerate the refrigerant. With the steam-turbine centrifugal,

steam drives the turbine, which operates the compressor to

drive the mechanical vapor-compression cycle. For more detailed

discussion, see the ASHRAE Handbook.3 Let’s compare

these two system types on a number of important parameters.

Capacity

Two-stage absorption chillers are available over a wide capacity

range: from about 100 to more than 1,500 tons (350 to

5300 kW). Steam-turbine centrifugal chillers are available from

a few hundred to as high as 5,000 tons (17 600 kW). So, an

overlap exists in the range of these chiller types, which is an

area requiring consideration in each potential application.

The cost of steam turbines is relatively fixed due to their

significant machining content. On the other hand, the cost of

a two-stage absorption chiller is generally proportional to

the capacity of the chiller. Broadly speaking, these characteristics

mean that the absorption chillers generally are more

cost-effective at capacities less than 1,000 tons (3500 kW),

while the steam-turbine centrifugal chillers are generally more

cost-effective at capacities above 1,000 tons (3500 kW).

Efficiency

With both chiller types, energy usage is measured in the

same way: enthalpy of supply steam minus the enthalpy of

the condensate returned to the steam-generating source. For

the two-stage absorption chiller, the steam is fully condensed

but the cycle efficiency is low. For a steam-turbine centrifugal

chiller, the steam leaving the turbine is only partially

condensed. At less than 115°F (46°C), the steam enthalpy is

usually not sufficient to be used as a further energy source,

but it must be fully condensed in a steam condenser so that it

may be returned to the steam-generating source. This is, thermodynamically,

an unavoidable energy expense. In spite of

this loss, the steam-turbine chiller’s IPLV is higher: 1.8 vs.

1.3. The reason is more efficient performance at off-design

conditions, as explained later.

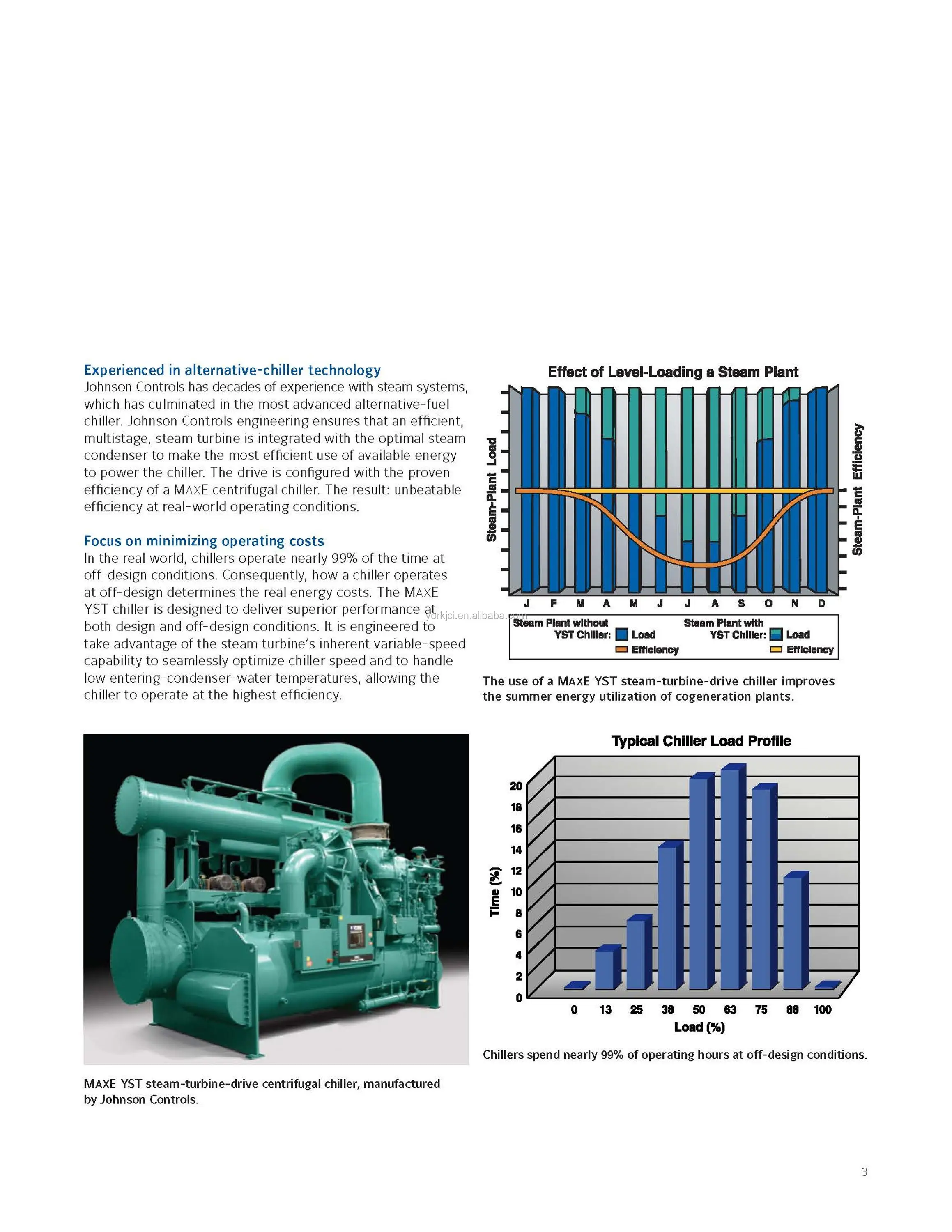

One factor that has a significant effect on off-design per

formance is entering condenser water temperature (ECWT).

It is a rule of thumb that lower ECWT means less energy

input to the chiller for a given cooling load. Steam-turbine

centrifugal chillers can operate with ECWTs as low as 55°F

(13°C), while two-stage absorption chillers have a minimum

ECWT of 70°F (21°C). Figure 1 shows a typical ECWT vs.

cooling-load profile, and highlights the requirement for maintaining

the ECWT above minimum levels at low loads. All

other factors being equal, the steam-turbine centrifugal chiller

uses less energy when the ECWT is between 70°F and 55°F

(21°C and 13°C).

The second factor that has a significant effect on off-design

performance is variable-speed drive. The most efficient means

of controlling a centrifugal compressor is with a variable-speed

drive. On electric chillers, the drive is an add-on component. On

the other hand, steam turbines have the inherent capability to

change speeds. So, at reduced cooling loads and reduced ECWT,

the steam-turbine centrifugal chiller becomes very efficient.

At design conditions, both steam chiller types have a similar

COP. However, the steam-turbine centrifugal chiller offers

superior performance at off-design conditions. As a result, it

has a higher IPLV (Figure 2).

Floor Space

Enhanced surface tubes in the refrigerant evaporator and

condenser significantly improve heat transfer rates for halocarbon

refrigerants, but offer little benefit where water is the

refrigerant. Because the steam-turbine centrifugal chiller uses

a halocarbon refrigerant, enhanced surface tubes allow compact

heat-exchanger shells. In the absorption chiller, which

uses water as its refrigerant, the shells tend to be larger for a

chiller of equal capacity. For example, the footprint of a 1,500

ton (3500 kW) two-stage absorption chiller is about 310 ft²

(28.8 m²), while a steam-turbine centrifugal chiller of the

same capacity has a footprint of only 170 ft² (15.8 m²), an

80% savings.

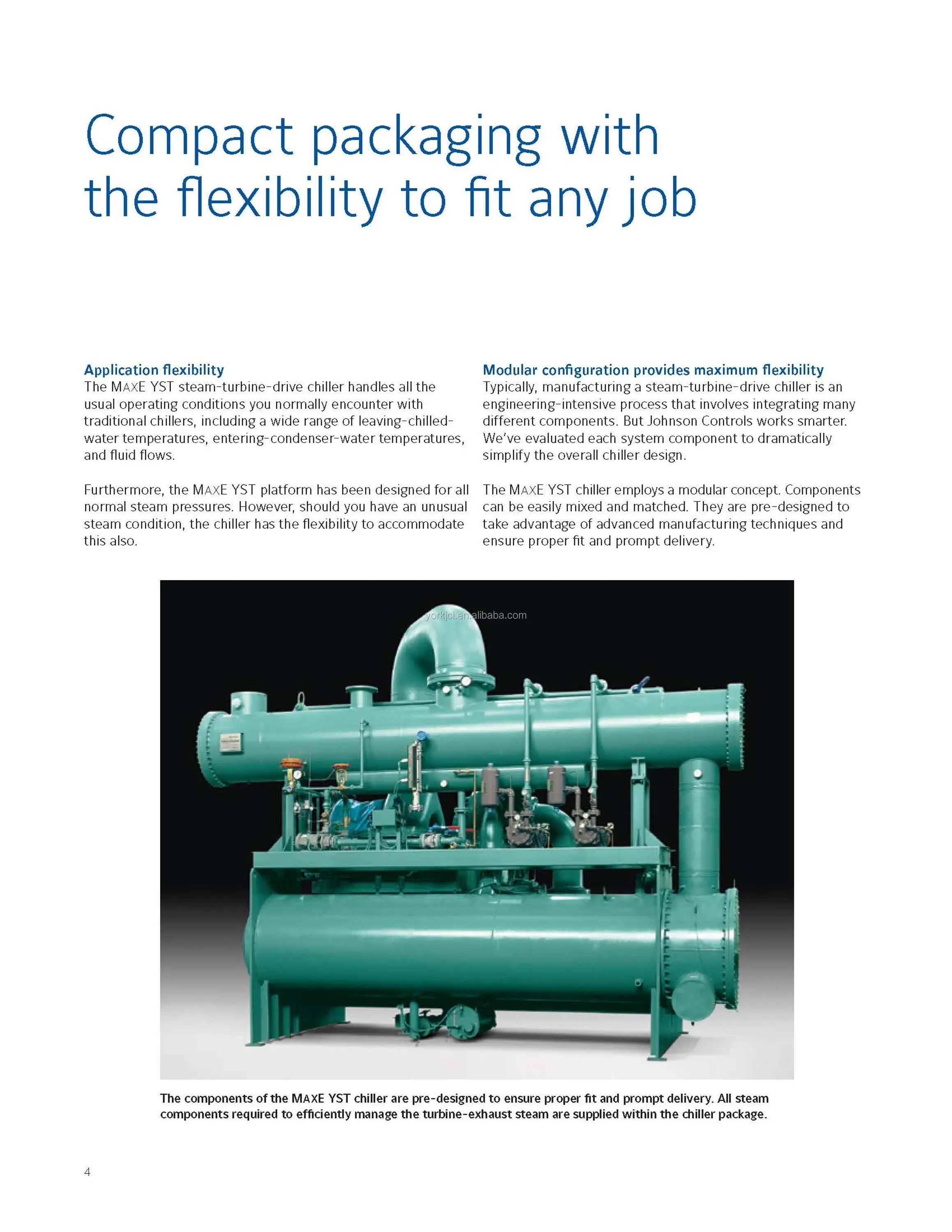

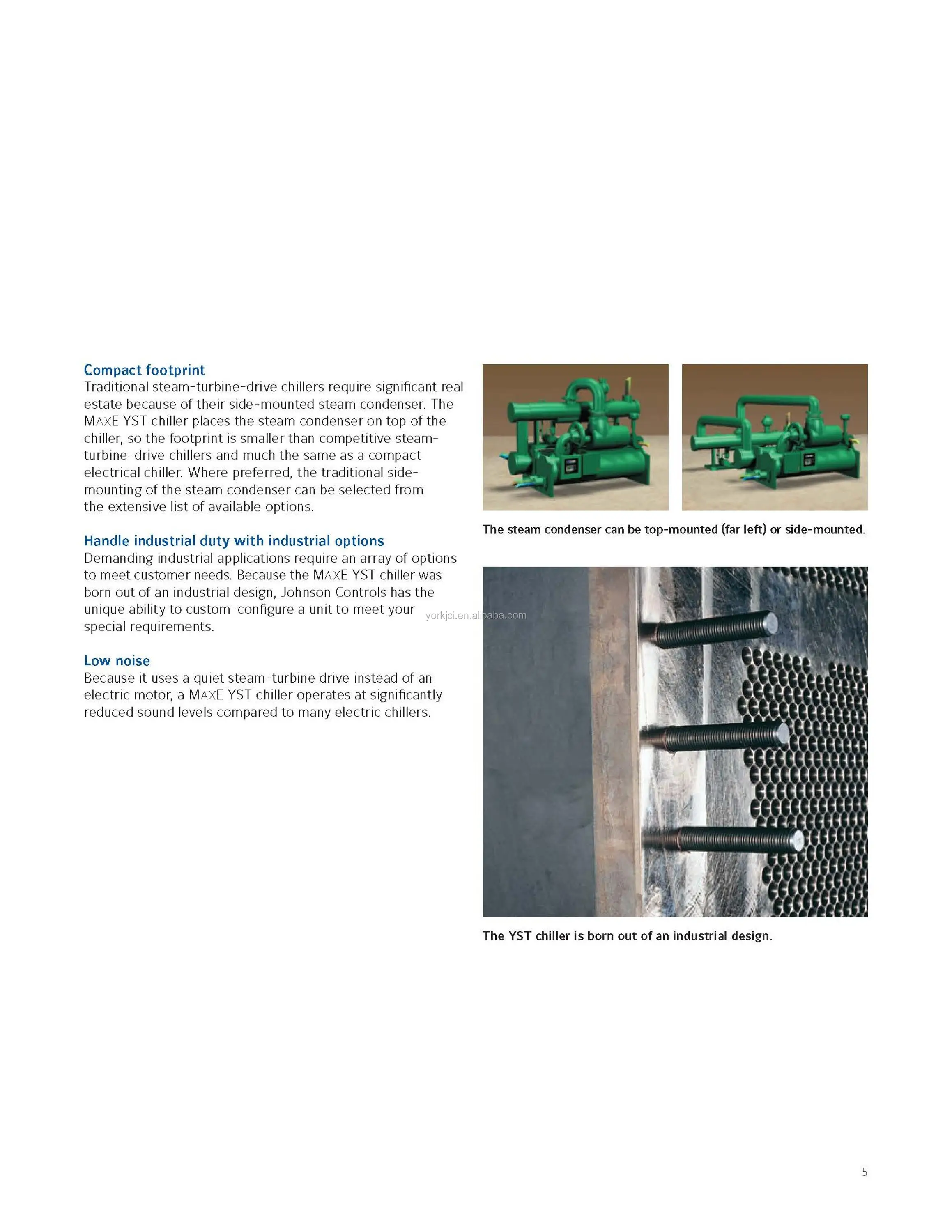

Current centrifugal models also use factory packaging of

components to reduce the floor space required by their predecessors.

The steam condenser can be mounted on top of the

refrigerant condenser — an option only recently available.

Installation

Compared to electric chillers, both steam chiller types require

a little more consideration during installation. The use of steam involves more piping connections (steam supply, condensate

return, air supply) in addition to the usual chilled and

condenser-water piping. If the absorption chiller capacity is

large, it may require a two-piece shipment that requires assembly

at the site. The steam-turbine centrifugal chiller requires

installation of the steam condenser (usually shipped separately

from the chiller), and installation of the steam piping from the

outlet of the turbine to the inlet of the steam condenser. On the

other hand, when compared to earlier steam-turbine centrifugal

chillers, the amount of field installation required for current

generation chillers is much less, due to an increased level

of factory packaging.

Controls

Microcomputer control centers have become standard features

on both chiller types, permitting sophisticated control

capabilities. On the two-stage absorption chiller, a “pulldown

demand” feature permits ramp loading of the input steam flow

on startup. Programmable inputs include initial pulldown valve

position and duration of pulldown demand period. This effectively

prevents the chiller from drawing more steam on startup

than the steam system can provide. As a result, the chiller avoids

sudden steam system pressure loss and associated problems,

such as boiler water carryover.

Remote steam-limiting control permits steam limiting based

on a remote signal generated from the building automation

system (BAS). Consequently, the BAS can prioritize steam

usage between the chiller and other processes without operator

intervention.

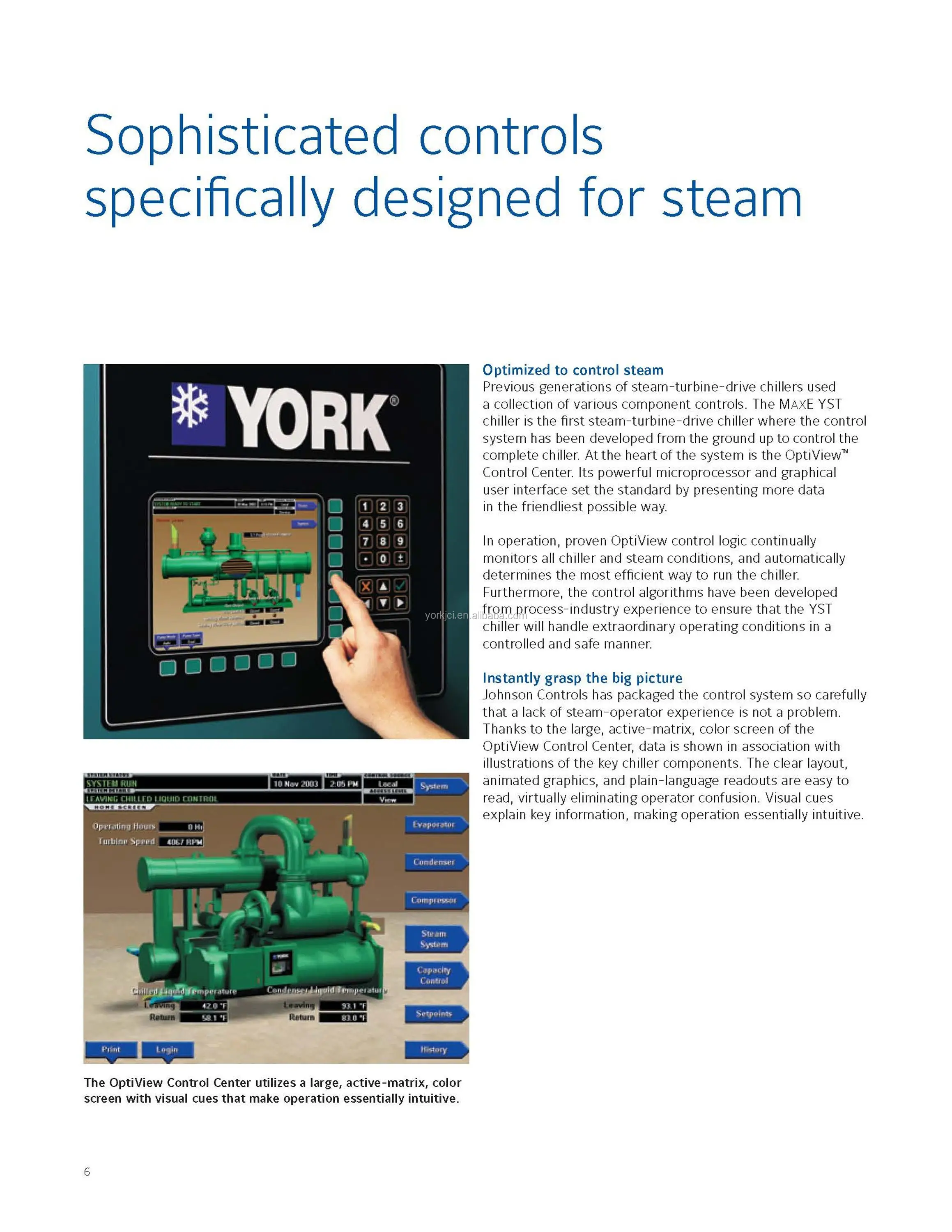

On steam-turbine centrifugal chillers, the introduction of

microprocessor controls allows all the system components to

operate together in the most efficient manner — a task that

was not possible with older control technologies. Traditionally,

an amalgam of various component controls had been applied

to steam-turbine chillers. More integration of components

results in more integration of controls. Although new, microprocessor-

based, graphical control centers present more data,

they are more intuitive and simpler to use (Figure 3).

Perhaps the area where microprocessor controls have had

the biggest impact on steam-turbine centrifugal chillers is in

the area of chiller startup. With older style chillers, operators

had to be specially trained for the manual startup process. Hot

steam entering a cool turbine resulted in some condensed

water, which had to be drained before the turbine could be started. The steam could also create temperature gradients

within the turbine, which would cause damage on startup if

not equalized. So, the turbine had to be slowly rolled to warm

all portions to proper temperature.

By contrast, today’s control centers can “prompt” an operator

through the entire startup process, which reduces the training

required. Also available is an option for a “fully automatic

start” capability. This can make the chiller as easy to operate

as an electric chiller.

Summary

High electric costs (caused by demand charges or RTP rate

structures) and/or low steam costs can make a hybrid

electric/steam plant financially attractive. Medium-pressure,

two-stage absorption and steam-turbine centrifugal chillers offer

the best IPLVs and latest technical developments. Thus, if

medium-pressure steam is available to the chiller plant, and

energy rates are favorable, the latest steam-chiller technology

is worth considering in new and retrofit plant designs.

References

1. Smith, B. 2002. “Economic analysis of hybrid chiller plants.”

ASHRAE Journal 46(7).

2. International District Energy Association, www.districtenergy.org.

3. 2002 ASHRAE Handbook — Refrigeration, Chapter 41: Absorption

Chillers; 2000 ASHRAE Handbook — HVAC Systems and Equipment,

Chapter 7: Steam Turbines.

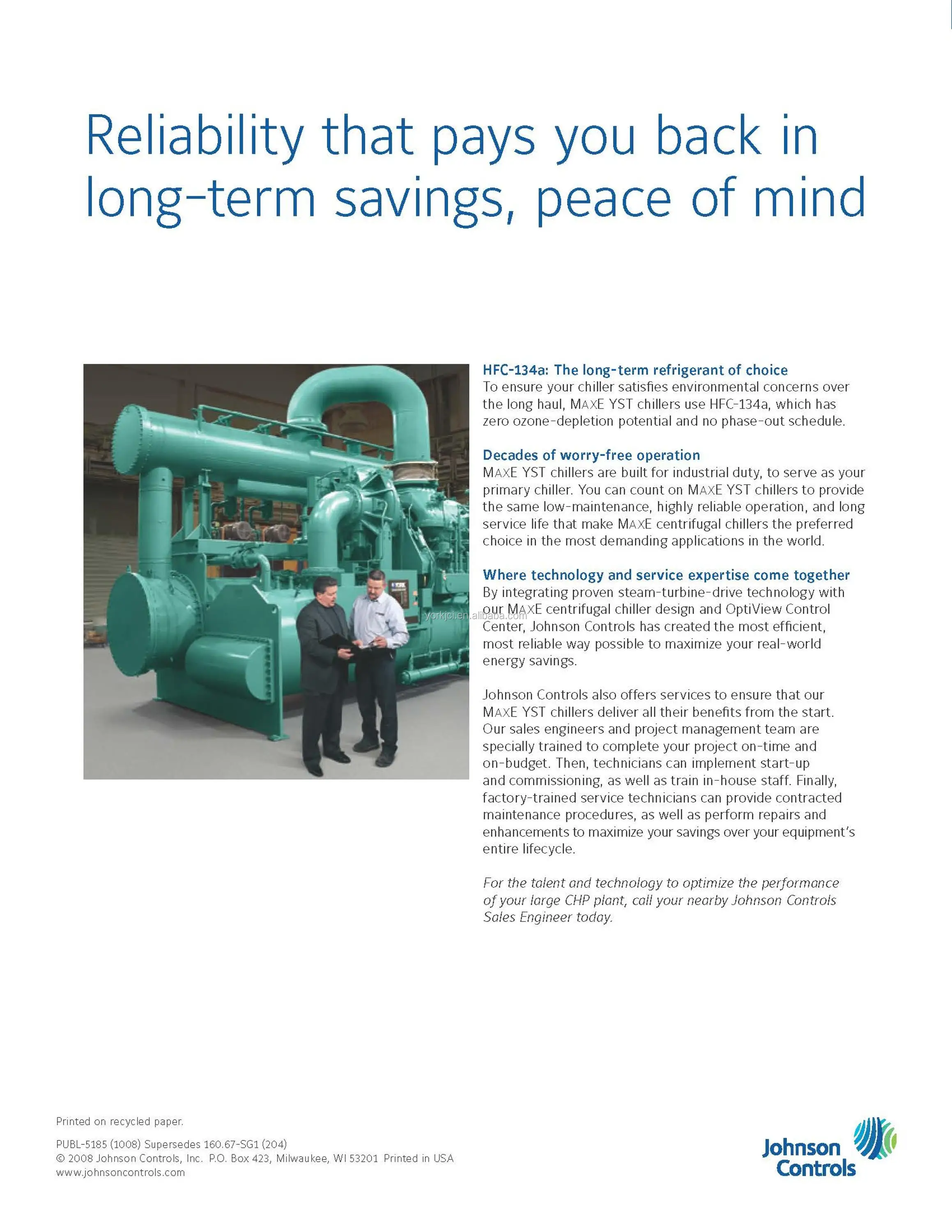

The Comcast Center, University of Maryland’s

new 470,000 ft2 (43 700 m2) basketball arena,

includes a 2,100 ton (7400 kW) chiller plant with

one electric-drive centrifugal chiller and one steamturbine

drive centrifugal chiller, each using R-134a

refrigerant and each sized at 1,050 tons (3700 kW).

The Center houses the 18,000-seat main arena,

athletics administration offices, an academic

support center, a 1,500-seat gym, and a

multipurpose room for social events. Major events,

including basketball games, occur in the arena

about 100 times a year, mostly from September

through May.

Engineers had to consider this variable, diversified

load when designing the HVAC system. The

projected life-cycle operating cost of a hybrid plant

vs. an all-electric plant showed that the hybrid plant

could save almost $70,000 annually in energy costs.

The university buys its energy from a utility

company that provides electricity, gas, and steam

as well as cogeneration capability. Electricity from

the cogeneration plant is used to base load the

campus’s power requirement (18 to 19 MW)

and reduce the purchase of supplemental power

during times of high demand (the campus’s peak

load is 35 MW).

In keeping the cogeneration plant operating at

peak efficiency, the campus produced excess steam

(not needed for heating during warm weather

months). Because this steam is available to the

Comcast Center plant, the plan is to operate the

steam-turbine chiller as the base-load machine

through hot weather, then use the electric chiller to

meet cooling loads occurring in the shoulder months.

However, that operating strategy could shift as

energy prices and rate structures evolve.

The hybrid plant is designed in a conventional

fixed primary/variable secondary flow

arrangement, with 100% variable-flow pumping.

The steam-turbine chiller uses steam at 110 to 120

psi (760 to 830 kPa) supplied from the onsite

cogeneration system.

Chilled water is supplied at 44°F (7°C) to 29 airhandling

units equipped with electronic variablespeed

drives. Eight main AHUs serve the basketball

arena, each with a capacity of 45,000 cfm (21 200

L/s). The arena was designed to maintain ventilation

airflow at 7.5 cfm (3.5 L/s) per person per hour. This

complies with ASHRAE guidelines because of the

short duration (up to three hours) of a basketball

game. Overriding this, the ventilation system can

supply as much as 100% outdoor.

Qinhao Zhan

HVAC&R Engineer

Refrigeration and Process Systems

China Refrigeration (York by Johnson Controls)

Mobile:+86 13818154378 18625150627

QQ: 826554493

862417098

Johnson Controls York Industrial Refrigeration - Shanghai Jiusui-Ref Systems Engineering Co., Ltd.: harsh industrial environments breakthrough in industrial refrigeration + accuracy + = large cooling load fluctuations York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd tailor-made industrial refrigeration systems!

Provide personalized solutions for five major areas! Can be mainly used in petroleum, petrochemical process; chemical technology; synthetic rubber technology; fertilizer production process and chemical fiber textile technology. A number of other applications to meet different needs!

In addition to the above five major areas, York- Shanghai Jiusui-Ref Systems Engineering Co., Ltd Industrial refrigeration approved for use in air separation plants, liquefaction plants, carbon dioxide recovery systems, pharmaceutical industry, tobacco industry and steel plants, power plants, electronics factories and other process cooling And refrigeration systems.

York Shanghai Jiusui-Ref Systems Engineering Co., Ltd is located in the petrochemical industry, whether it is upstream natural gas compression, midstream liquefied natural gas storage, transshipment, or downstream air separation, liquefaction unit, as long as the compression-related York- Shanghai Jiusui-Ref Systems Engineering Co., Ltd are involved!

Advanced control system + energy efficient refrigeration equipment + overall solution = York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd a full range of food refrigeration business!

Food processing + large cold storage + poultry slaughter + beer drinks + dairy products + aquatic fisheries + small logistics distribution center, etc. = York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd food refrigeration business coverage!

P.K. "China cold village" -58 ℃ low temperature! (-28 ℃ ~ 15 ℃), and even tuna low-temperature cold storage (-55 ℃ ~ -60 ℃), York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd food refrigeration business can be, but also the production of cold storage, Complete turnkey project. Diverse demand one stop to meet! Supporting cold storage products with cooling water system to meet the dairy products, beer and other light industry diverse needs. Sea and land to eat to ensure the quality of fish and shrimp! Provide on board and onshore fish and shrimp processing supporting the cooling and quick-frozen products, stable and reliable products to York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd frozen food business filled with full.

Hot summer experience! Not only in the game-type ice rink and entertainment ice rink unique advantages, but also for the automatic ice-making plant and ice cream factory to provide frozen solution.