Brand Name: CABLECRAFT/PHIDIX, CABLECRAFT/PHIDIX

Model Number: OEM

Place of Origin: Shanghai, China (Mainland)

[Push-Pull Standard Control Cable Assembly]

Description: Applications: Features:

Push-Pull Standard • Implement control • Typical temperature range

Industrial Control • Throttle control -65°F — 230°F (Bristow)

Cable Assembly • PTO/4WD activation -65°F — 230°F (Utility)

• Valve actuation -65°F — 230°F (Low Friction EXT)

• Remote battery disconnect -65°F — 230°F (Low Friction)

• Remote electrical disconnect • Tough/durable materials

• Transmission shift • Long lasting seals

• Hydrostatic drives • Environmentally protected

• Latches

Material: End Fittings

• Stainless Steel or • Full Range

Plated Carbon Steel

• Plastic Coated

Carbon Steel

Conduit and

Innermember

• Plastic Seals

[Push-Pull Industrial]

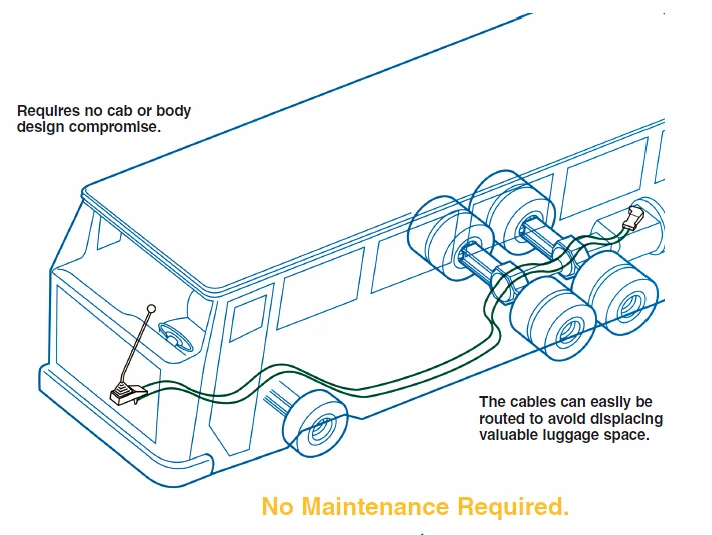

Cablecraft Motion Controls offers a full range of push-pull controls that provide a means of transmitting linear motion from one location to another. They offer ease of installation as well as superior performance.

The Bristow® Typecontrol is an economical construction for applications which do not require tight bend radii, and are temperature rated for use from a low of -65°F to a peak of +230°F.

The Utility Styleadds a binder wire for structural integrity and a tighter minimum bend radius than other controls.

Low Friction EXTcontrols have the same advantages as utility with an added

plastic covered innermember which provides improved efficiency.

Low Frictioncontrols provide the standard of excellence for industrial controls. Features include a binder wire for structural integrity, tight minimum bend radius, and PTFE covered innermember for the ultimate in efficient, smooth operation. Temperature rated for use from a low of -65°F to a peak of +230°F, they will provide long life in the most demanding applications.

[Push- Pull Standard Description]

The Cablecraft® Time Proven Design— The design of today's Cablecraft control has evolved from over 54 years experience in meeting a wide variety of industrial, ordnance, marine and aircraft applications. Combined with careful selection of materials and fabrication methods, this design provides users the most versatile, highest quality control available today.

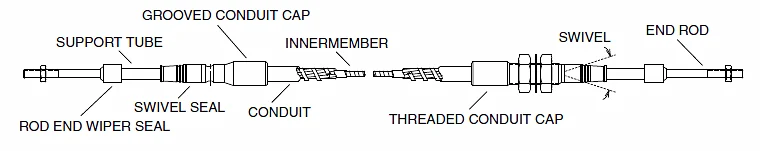

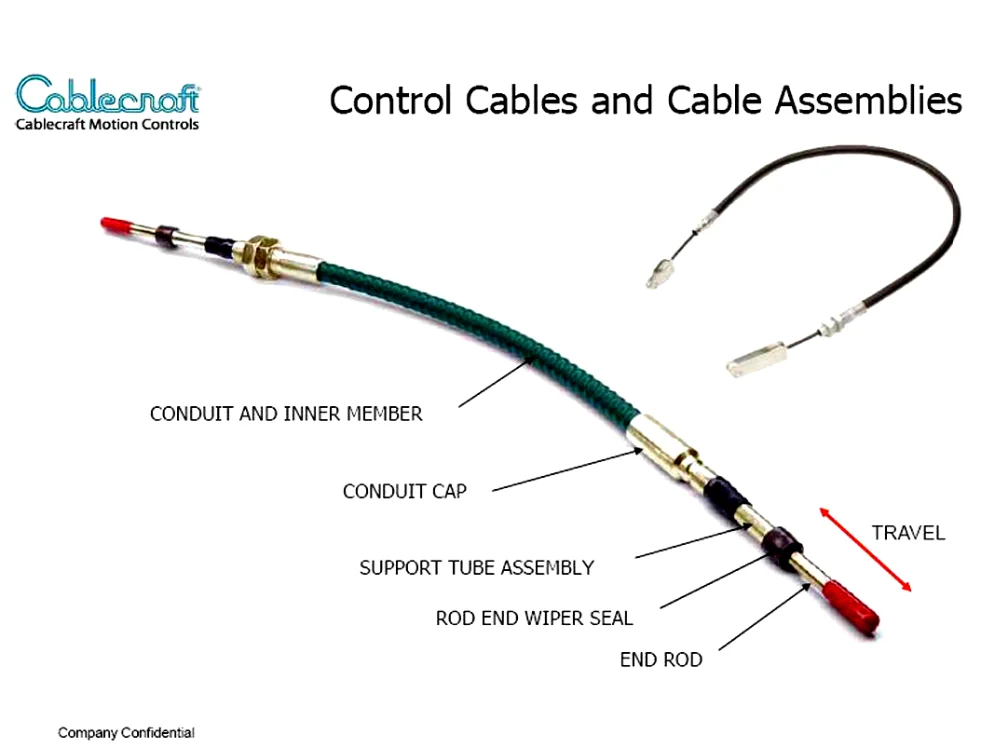

End Rod and Support Tube— All standard Cablecraft controls may be ordered with either type 300 stainless steel or protectively plated carbon steel end rods and support tubes. Choose the material to best meet your requirements.

End Rod Seals— Rod wiper seals have been carefully designed to prevent entry of moisture and contamination into the support tube and to provide a bearing surface for smooth motion of the end rod. Two types of rod wiper seals are available (see seal options in ordering code), capable of meeting a wide range of environmental conditions.

Improved Model 5 Floating Wiper Seal— All Utility, Low Friction, Low Friction EXT and Bristow® controls are equipped with the new improved molded plastic Model 5 seal unless otherwise specified. Extensive testing and field experience have proven the ability of this seal to protect the control in contaminated environments. Security tabs hold the seals in position and an internal support tube bushing improves end rod alignment.

Model 6 Floating Wiper Seal System— The Model 6 seal system is offered as an option on all Cablecraft Push-Pull control cables. It is designed to provide a tighter fit with the surface of the rod end and an internal o-ring is added at the swivel joint of the support tube for additional protection. The Model 6 seal system provides additional sealing for use in extreme environmental conditions. Because this seal produces additional load friction to a push-pull control cable, it is recommended for applications which can tolerate extra friction.

Swivel— The swivel joint between support tube and end cap is designed to allow 8 degrees minimum swivel from the control centerline.

Swivel Seal — Protection of the swivel joint from entry of moisture and contamination is provided by a molded seal. On LD and larger sizes, mounting nuts for threaded type conduit fittings may be removed without removing the swivel seal.

Conduit Caps— All standard Cablecraft controls have plated steel conduit fittings. Special controls

designed for marine and aircraft applications are available with stainless steel or brass fittings.

Conduit— Four types of conduit construction are available to meet various requirements — Low Friction, Low Friction EXT, Utility and Bristow. See "Cablecraft Control Selection" data and individual specification pages for construction and performance information. These standard conduits are covered with a tough plastic casing for protection against corrosion and abrasion. Color coding of the casings allows easy identification of the control type:

Low Friction-Green

Low Friction EXT-Green

Utility-Gray

Bristow-Black

Inner Operating Member— The inner operating member for all standard Cablecraft controls is made of flexible 1 X 19 strand, armored with a swaged steel jacket for efficient operation and compression strength. Stainless steel inner operating member is available for added protection in corrosive environments. In Low Friction controls, a coating of PTFE provides superior efficiency and reduces "stick-slip" during operation. Note: VLD Bristow is a solid wire, Low Friction EXT is plastic covered, Utility is uncovered.

Lubrication— All standard Cablecraft controls are lubricated during construction with carefully selected compounds to provide optimum performance. No further service is necessary or recommended.

Installation— Mechanical stops should be implemented at or below the travel desired (ie. 1,2, 3, 4, 5, or 6) on the equipment on which the cable assembly is being installed. Internal damage may result if end rod is allowed to bottom inside conduit cap.

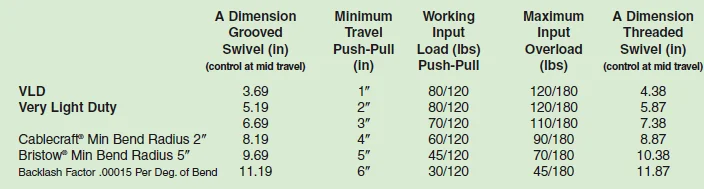

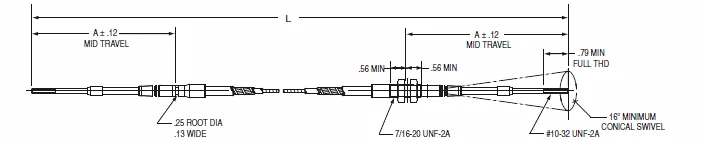

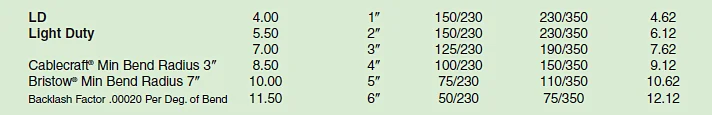

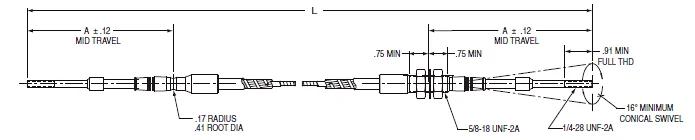

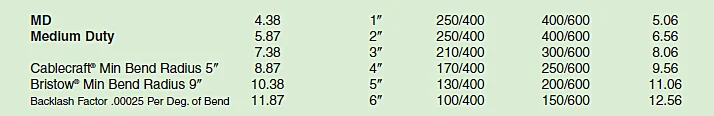

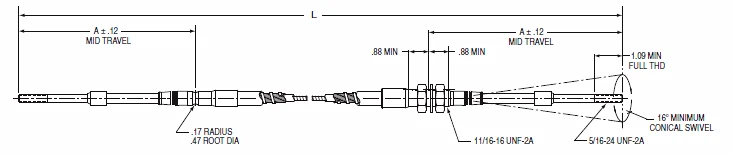

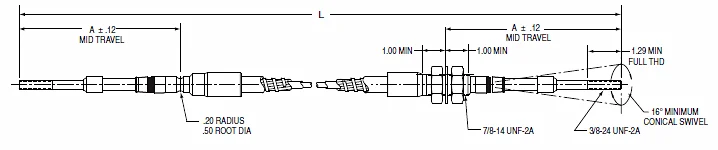

[Push-Pull Standard Specifications]

All line art dimensions are represented in inches

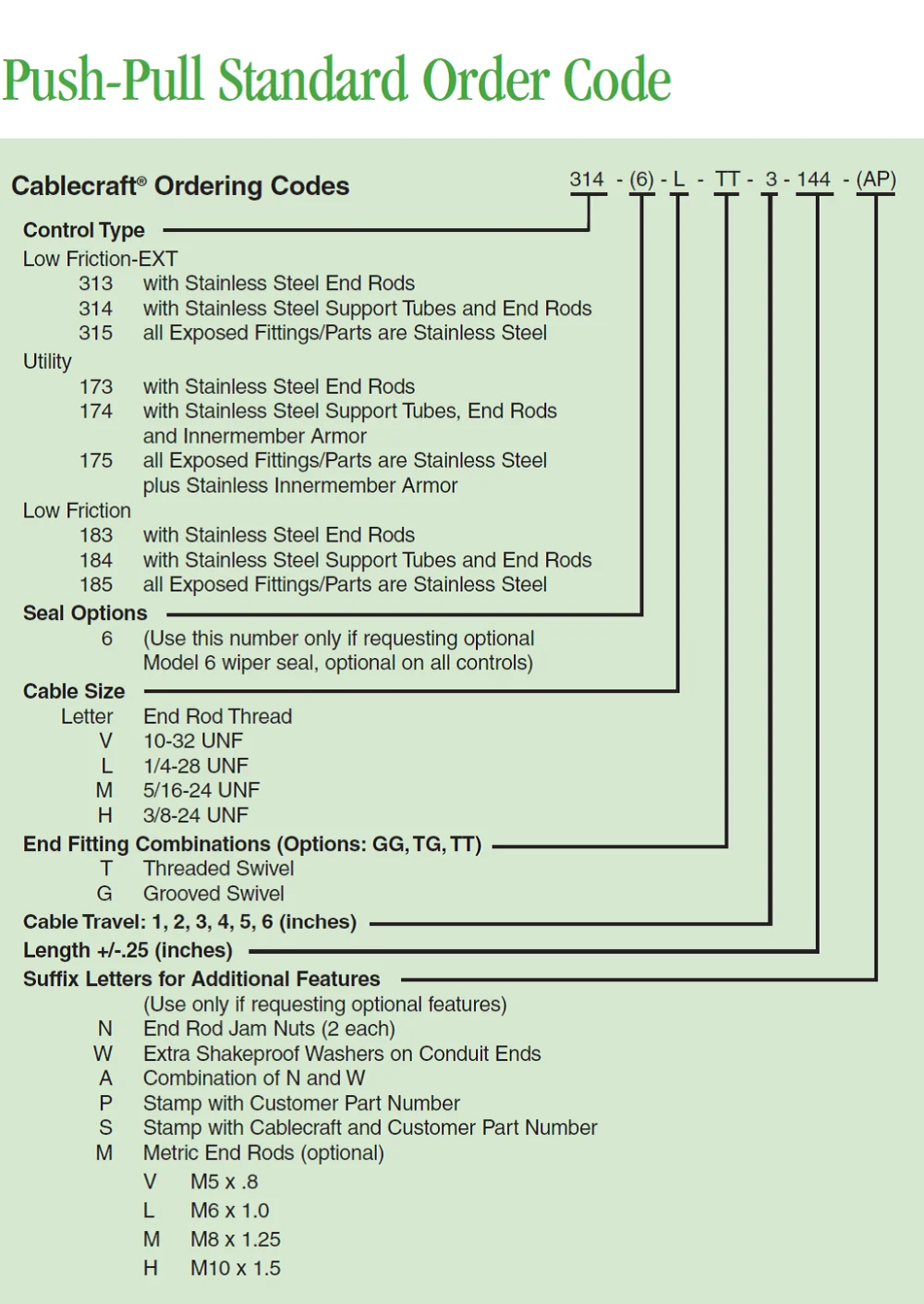

[Push- Pull Standard Order Code]

American TUTHILL Corporation is headquartered in Chicago, has a history of one hundred years of family enterprises and multinational companies, with a wide range of business scope. The company is named by "TUTHILL group" in China. The control group is the independent subsidiary. By the end of 2010, the control group from TUTHILL group split up for independent operation. Control group have factories in the United States, Britain and Germany, offering high-end drive control products and engineering solutions. The product line includes control flexible shaft of the various specifications, cab units and a category range of standard parts, widely used in high-end industrial customer markets, such as luxury bus, heavy truck, aerospace, construction machinery, rail transportation, agricultural machinery, gardening equipment, racing cars, military vehicles, tanks etc. as selection of shift control, throttle cable, clutch cable, brake line, valve and other mechanical transmission control. In China, as imports of high-end brands on behalf of "TUTHILL flexible shaft" with its exquisite craftsmanship and quality, these products have received high reputation from the industry.

If you are interested in our products,please tell us which model,quality you want to order.

A performa invoice will be made for your order.

We will deliver the product ASAP when we receive your payment.

Lead time usually within 25working days.

Please contact us without hesitation, we are pleased to welcome to you!!!

PHIDIX MOTION CONTROLS(SHANGHAI) CO.,LTD

Add: Building #21, Block 9299, Tingwei Road, Jinshan District, Shanghai 201505

Tel: (86-21)37214606/ 07/ 08/ 09

Fax: (86-21)37214610

MP: 13916612486

Website: www.phidixglobal.com

E-mail: info @phidixglobal.com