Brand Name: Laiyuan

Model Number: LY-CP16002

Place of Origin: Jiangsu, China (Mainland)

BEST SELLING MANUFACTURER CERAMIC HEATING PARTS FOR ELEMENT

Introduction: Best Selling Manufacturer Ceramic Heating Parts For Element

The product is ued in controllable aural various heat treatment furnace,to avoid the contact of elding burning outcome or to avoid the corrosion of furnace gas to heating element.The process(the conversion of elding burning or electric energy) is put into refractory steel tube and let amount of heat radiate by wall of tube.This device is called as heater tube.

Electrothermal heater tube will close the heating element in the jacket,after electrify and heat up,the heat is indirectly radiated to furnace liner and workpiece to be heated by bushing.The heat up of heater tube is used in furnace with going protecting aural and corrodent aural,such as continuous furnace,roller furnace, pit furnace.

Twist and turn resistance wire in axial direction,that is,the single resistance wire is bended to U shape,then in series or parallel connection mutually.This kind of electrothermal heater tube is called bending resistance wire heater tube.This tube,because fall of screening of resistance wire,in intratubal upper surface load,can insure prolong life span.

Advantages: Best Selling Manufacturer Ceramic Heating Parts For Element

1.The controllability of aural inside furnace can be guaranteed.

2.The control of temperature,assemble and maintainace are very convenient and can be easy to sealed.

3.The cubage of hearth is enlarged and throughput is improved because of no muffle pot

4.Strong heating ability and high efficiency

5.The refractory steel material is save.

Usage: Best Selling Manufacturer Ceramic Heating Parts For Element

1) Avoid to heat over the temperature and overload for long time

2) When the furnace temperature higher than 400 degrees, avoid to be cold immediately.

3) Unload and load the material can’t touch the ceramic heater

4) Pay attention to the red and blue buttons when the furnace on work, and change regularly when on thermal insulation

5) Pay attention to the instrument meter, and deal with in time when the furnace temperature is not matched with the meter.

6) The furnace Capacity over 100KW, it’ll be better to fix the ammeter for check in every heat area.

Protection:

1) After using three to four months, take the ceramic heater, and pour-out the dust in the ceramic heater, and tuner the heater 180 degree.

2) Pay attention to the positive and negative pole, and two to four months make a change.

3) Can touch and hit the heater when take it out.

4) Check the screw regularly for the oxidation looseness,Laiyuan.

Order parameters: Best Selling Manufacturer Ceramic Heating Parts For Element

1.Pls supply Drawing or sample, if no pls supply Size,type ,voltage,power,length,diameter etc related information of ceramic bobbin heater.

2.We also can supply drawing for our client reference according to the requirement.

Best Selling Manufacturer Ceramic Heating Parts For Element

1.Laiyuan is Factory or Trade enterprise?

Laiyuan is an enterprise incorporating Factory and Trade .

2.Where is your factory located? How can I visit there?

Our factory is located in Yancheng City, Jiangsu Province, China .

It is closed to Shanghai ,only 4hours if by bus.

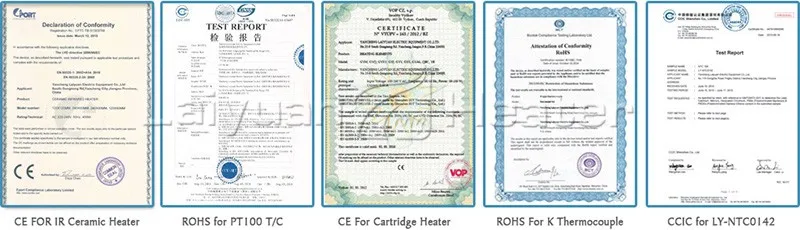

3.Which Certificate of your product does your company have?

ISO9001,CE,ROHS.CCIC

4.Before order, we need sample for test ,is it ok?

Yes, of course. We provide sample for test before bulk order.

5.How does your company to control your product quality?

Quality is the cornerstone of the survival and development of Laiyuan .

We control quality from the beginning to the end all the time.

6.How to contact me ?

Whatsapp: 86-15861946714 Phone:86-15861946714

Skype: laiyuan001 E-Mail.: sales001ATchina-laiyuan.com.

YOUR VISIT WILL LEAD LAIYUAN PEOPLE TO DO BETTER!