Brand Name: Jinhefeng

Model Number: W4-P2

Place of Origin: Guangdong, China (Mainland)

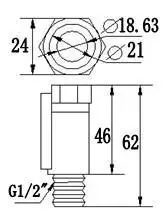

Flow switch instructions

Figure 1 Figure 2

Rated power |

10W |

50W |

Switching voltage max |

200VDC 140VAC |

300VAC 350VDC |

Switching current max |

DC 0.5A AC 0.5A |

DC0.7A AC0.5A |

Carry current max. |

1A |

2.5A |

Ambient temperature |

-20~85°C |

|

Housing material |

PP |

|

Float ball material |

PP |

|

Float SG |

0.7 |

|

Fitting type |

M8 |

|

Lead wire |

22 AWG |

|

potting |

Pu/Epoxy |

|

The flow switches are installed on the water pipe through series connection or parallel connection,It is used hydraulic pressure (air pressure) to drive magnetic induction and convey switch signals.

The water flow switches send on or off signal according to the flow volume, it is an important component of the fluid flow controls system.If the flow in the pipe is lager than start-up volume, the magnetic valve will be moved by the force of flow pressure, and then it will trigger the reed switch that same sealed in the vavle and send the signal . When the flow volume reduce lower than the start-up volume,magnetic valve core will be forced back to theoriginal place by the reset spring in the vavle.

The flow switches series products

Flow switches Application

Gas and liquid dual-use, it can be widely used in industrial automation, machinery and equipment, industrial compressed air, refrigeration HVAC fields. Flow switch magnet is not flowing waterways, normally used for sewage system pipe.

Adaptation

1. Away from magnetic objects or environment.

2.Output signal is switching, the control object connections must also switch controlling relationship.

3 .the control object signal power shall not exceed the load capacity.

4. The aqueous medium control device is a device available for other medium control. A variety of size,

About US

Jinhefeng industrial electrical co., ltd is devoting to designs and manufacture the sensing switch for more than 10 years .we have striven and now provides some of the best sensor solutions for liquid level, in addition to pressure and temperature measurement, for the most demanding float switch applications. Whether you need a single point float switch or continuous liquid level sensor, JHF Company can direct you to the proper float switch and liquid level sensor solution. Our Company offers standard float switch sensors in stock for same day shipment, and can also custom configures multiple-point float level switches in only 3 days.

We manufacture float switches that stand up to harsh environments, hazardous locations and pressures,sanitary and food grade. Many JHF float switch designs meet agency approvals like ROHS and ISO,and our sensor are widely used the food and beverage ,medical equipment ,industrial equipment and etc.

Whether you need a float switch, continuous liquid level sensor, pressure or temperature sensor, utilized in Water and Waste Water Tanks, Food and Food Processing Equipment, HVAC, Specialty Vehicles, Medical, Marine, Washing Equipment, or any Industrial Application, let JHF provide it.

Our cooperation cargo and the payment