Brand Name: RGP

Model Number: D96-32

Place of Origin: Guangdong, China (Mainland)

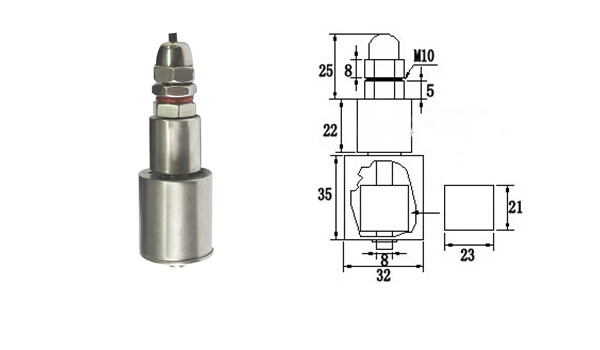

D96-32 magnetrol level transmitter

Description

OEM make anti corrosive magnetrol level transmitter D96-32 (see Figure 1) new designed, for vertical mount reed switch type contoller , it is made of SUS304/316 , one of our hot sell products. with slosh shield protect ,suit for high temperature and steaming liquid , It is robust construction anti corrosive ,can be easily install and used,

when mounted stemp up operating functions are reversed,safely and reliablely to control the level of the

liquid , it has smaller volume than mechanical switches, and high speed, longer life, stronger anti-load impact to compared with the electronic switch. It without complex circuit ,won't be disturbed by electric ,and easy to use to control.

Figure 1 Figure 2

A: The components.

1: The main stem material: SUS304

2. The float material: PP

3. Slosh shield protect(stainless)

4. Assembly: Reed switch magnet ,Epoxy

5. Lead Wire.30 cm(Teflon).

6. Cir-clip,stainless nut

B: Working principle:

The float switch utilize the liquid buoyancy principle, along with the liquid pressure (water level) the duckbill float will move up and down ,the it will trigger the reed switch that sealed in the the stainless stem ,the magnet arm will be affected, and send the connect (ON) or disconnect (OFF) signal.

C:The installation instructions (see Figure II)

1.on the bottom or the ceiling of the tank,vertical mount, No( open) or NC (closed) due to the installation position.

2. The total length of 0182-S is 82 mm, the connect use the M10 stand thread,f diameter of the connector thread is 10 mm, length is 15mm , height is 5mm ,hex stem length 23mm,

3. Unscrew the nut ,via the hole at the bottom or at the ceiling , then tighten the nut.

D: Instructions

1: The range of temperature -30 ~ 135 (high temperature 180 need to customized)

2: Suit for corrosive liquid and other liquid , and the viscosity of the liquid is not high stick, won’t be dry.

3. Parameter.

Max contact Rating |

10 W |

50W |

Max switching voltage |

200V DC |

300VDC/250VAC |

Max switching current |

0.5 A |

1A |

Max carry current |

1.0A |

1.5A |

Thread Diameter |

16mm(M10) |

|

The main material |

SUS304 |

|

The float material |

SUS304 |

|

Float SG |

0.75 |

|

Lead wire |

Length 30cm |

|

Approvals |

ROHS |

|

Note

The stainless steel series water level detector is designed specifically for liquid level sensing in

demanding fluid level sensor applications.

This durable stainless steel float switch is the perfect sensor for a wide range of liquids, from

high purity to high temperature or high pressure corrosive liquids

Our packing

Verticalmounted

E .Application:

Sanitary sensor switch that suit for a variety of food and beverage equipment ,medical equipment and industrial equipment,such as household appliances, humidifiers, chillers, fog machine, constant temperature and humidity level detection machines, printing machines, medical equipment, beverage

machinery, and pressure tank, the signal remote switch police, health, environmental, toxic, corrosive

liquid with acid use.

About us

Jinhefeng industrial electrical co., ltd is devoting to designs and manufacture the sensing switch for more than 10 years .we have striven and now provides some of the best sensor solutions for liquid level, flow control , for the most demanding float switch applications. Whether you need a single point float switch or continuous liquid level sensor, JHF Company can direct you to the proper float switch and liquid level sensor solution. Our Company offers standard float switch sensors in stock for same day shipment, and can also custom configures multiple-point float level switches in only 5 days.

We can combine our wide range of sensing technologies with numerous material choices to fit almost any application. We have material choices such as stainless steel, Polypropylene,PVC , Teflon ,copper etc. to ensure that you are provided with a sensor that will provide durability and long life.

The float switches are stand up to harsh environments, hazardous locations and pressures,sanitary and food grade, that designs meet agency approvals like ROHS and ISO.

Whether you need a float switch, continuous liquid level sensor, pressure or temperature sensor, utilized in Water and Waste Water Tanks, Food and Food Processing Equipment, HVAC, Specialty Vehicles, Medical, Marine, Washing Equipment, or any Industrial Application, let JHF provide it.

The float switch delivery cargo and the payment.

Customer service