Brand Name: REOU

Model Number: K type

Place of Origin: Jiangsu, China (Mainland)

K Type Thermocouple Wire

NiCr-NiSi (Type K) thermocouple wire

NiSi (Type K) thermocouple finds the widest use in all base metal thermocouple, at temperature above 500°C.

The main chemical composition of positive leg NiCr (KP) are Ni≈90% and Cr≈10%; negative leg NiSi (KN) are

Ni≈97% and Cr≈3%. The operating temperature range is -200~1300°C(for short term) and 0~1100°C( for

long term).

Type K thermocouple has strong resistance to oxidation than other base metal thermocouples. It has high

EMF against Platinum 67, excellent temperature accuracy, sensitivity and stability, with a low cost. It is

recommended for oxidizing or inert atmospheres, but cannot be used in the follooeing cases:

(1)Alternatively oxidizing and reducing atmosphere,

(2)Atmosphere with sulphur gases

(3)Long time in vacuum

(4)Low oxidizing atmosphere such as hydrogen and carbon monoxide atmosphere

Remarks: It can be made according to the customers' requirements

Package of k type thermocouple

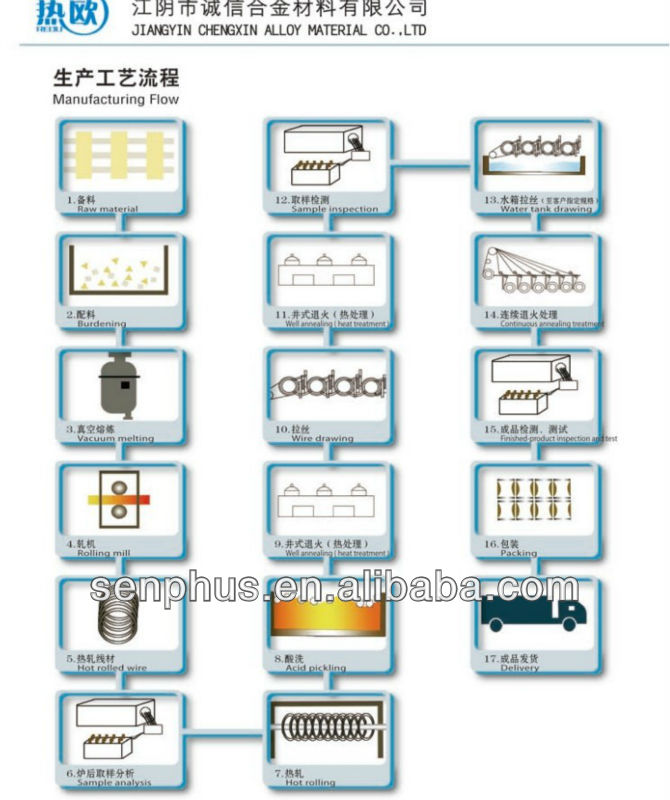

Manufacturing Flow of k type thermocouple

Factory of k type thermocouple

Senphus Electrical Material Co., Ltd was founded in 2003, which is a leading manufacturer of heating resistance alloy material in China. The main process equipments have reached the international level. The company worked out a complete, mature production process of heating alloy from smelting, steel rolling, drawing, heating treatment to the finished product, and established chemical analysis dept, physical testing dept, ect.

The company produces hundreds of types products with the "REOU" band, comprising over a thousand specifications under seven main categories. Copper-based low resistance heating alloys (CuNi1-CuNi44); precision resistance alloys (Karma, manganin and constantan); high resistance heating alloys (nickel-chromium alloy wire); thermocouple alloys (K, N, T, J type); thermocouple extension wire alloys; PTC thermistor resistance alloy and specialty wire (pure nickel wire and corrosion-resistant (Monel) alloy) with wire, strip, ribbon, bar, foil, sheet, stranded. The products have stable physical performance, high surface loading, oxidation resistance, high electrical resistivity and stable temperature coefficient of resistance, ect., so they are widely used in malitary project, aerospace, household appliances, heating wire, mechanical, electrical plant, temperature instruments, and many other field s. Due to the annual output of 1500 tons, and the KANTHAL level or more better quality, we become the designated supplier of many world-renowned brand.