Brand Name: Ujing

Model Number: 400M

Place of Origin: Zhejiang, China (Mainland)

The application of industrial desiccant dehumidifier:

1. Processing and production areas

Brewing

Chemical and petrochemical product

Electronic products

Wind power eneration

Food industry

pharmaceutical inductry

Synthesis of glass

Sandblasting processing

Bridges building

Rubber manufacture

2. storage

Corrosivity metal

Electronic products

Food

Military equipment

Precise instrument

Seeds

Sugar

3. Packing

Chemical product

milchigas

Fertilizer

so on.

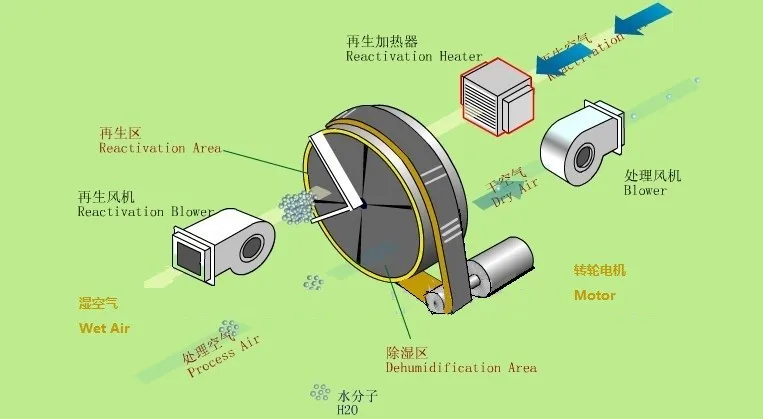

1.The principle of desiccant dehumidifier

The core part of desiccant dehumidifier is cellular structure desiccant rotor, formed by special ceramic fiber composite and silica gel. The rotor is divided into two area by a seal device, one is process area(dehumidification area), the other is reactivation area. When the dehumidifier is in operation, two streams of air pass through two areas simu 14.4L/D 200M Desiccant Industrial Dehumidifier ltaneously. One is the air that will be dehumidified by silica gel in rotor, the other is hot air used to dry the running rotor so that it will be able to remove moisture again. The moisture is taken away by the hot and very humid air steam.

| Model | 60M | 200M | 400M |

| Dehumidifying capacity (20°C, 60%) | 0.25kg/h | 0.6kg/h | 2.5kg/h |

| Process air flow | 60m3/h | 220m3/h | 420m3/h |

| Reactivation air flow | 25m3/h | 60m3/h | 130m3/h |

| Applied Temperature | -20°C-70°C | -20°C-70°C | -20°C-70°C |

| Max power | 0.4KW | 1.5KW | 2.3KW |

| Power rating | 0.38KW | 1.2KW | 2.0KW |

| Voltage | 220V | 220V | 220V |

| Current | 1.8A | 7A | 10A |

| Dimension | 313*288*425mm | 443*293*678mm | 590*420*900mm |

| Weight | 8kg | 35kg | 45kg |

| Applying space | 10M2 | 10-20M2 | 20-50M2 |