Brand Name: Peide Vacuum degasser

Model Number: PD-TJ Vacuum degasser

Place of Origin: Jiangsu, China (Mainland)

Vacuum degasser used in chilled water system

The vacuum deaerator is also referred to as:vacuum jet air exhausting device,vacuum exhausting device,vacuum degassing tank,vacuum degassing device,vacuum degassing unit and vacuum sputtering exhaust device,etc.

If there is gas in the heating and cooling system,the system will generate air resistance easily,so as to block the circulation of the system partially or completely.The increase of air resistance will disable the heating system and the cooling system.At the same time due to the water containing oxygen and makes heating (cooling) equipment,pipes and steel radiators have oxygen corrosion, leading to perforation,leakage.In the system,the gas can also cause the corrosion of the pump, which directly affects the safety of the whole system.Vacuum degassing method is used to remove the free gas and dissolved gas in the system,so that the system can operate safely and reliably.In the circulating water system,many users use the water softener,pump controlled pressurisation system,spiral dirt separator and vacuum deaerator cooperatively,which do not only reduce the scaling,stabilize system pressure and reduce the energy consumption,but also slow down the corrosion,reduce noise and water turbidity.

The vacuum deaerator is a new generation of circulating water system degassing device introduced by Peide Water Treatment Equipment Co., Ltd. from the developed countries,such as United States and England,through adopting world leading vacuum degassing technology.It solves the problems of poor circulation of the partial or entire system caused by gas,noise in the pipe network caused by oxygen,bad heat transfer effect of the heat exchanger in the heating and cooling system.Vacuum deaerator is an important part of the circulating water system.

The vacuum deaerator is widely used in HVAC circulating water system and it can remove the free and dissolved air and oxygen in the water effectively with the degassing efficiency of above 99%,which can solve the problems of air resistance and air block in the pipeline completely,eliminate the noise of pipe network system,slowly down the oxygen corrosion of radiator and pipe significantly,eliminate the cavitation of pump and prolong the service life.

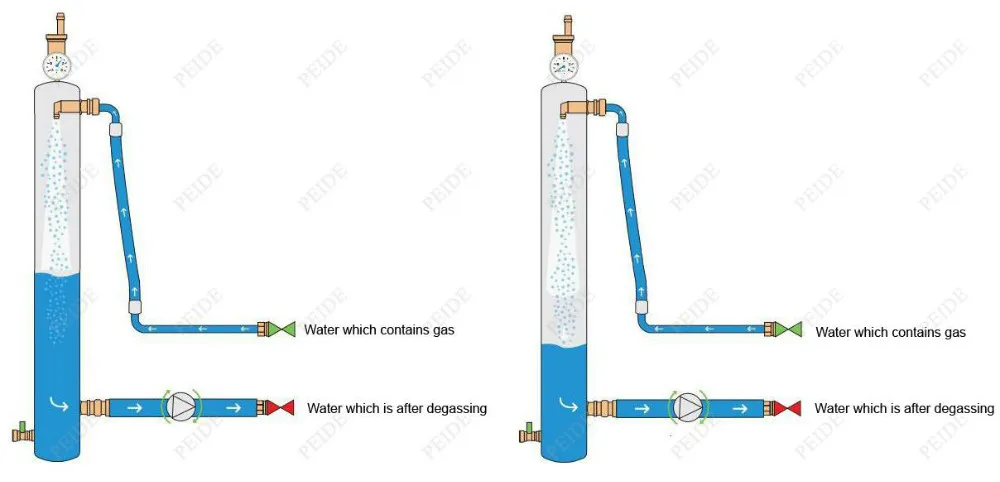

Working principle of Vacuum degasser

According to Henry's law,the solubility of gas in water is related to the water temperature and pressure. At a certain temperature,the pressure of the gas is proportional to the pressure.Under the pressure,the water temperature decreases,the solubility of the gas increases,the water temperature increases and the gas solubility decreases.When the water pressure is reduced,the gas can be dissolved in the water,so that the gas in the water can be removed.Vacuum deaerator is through the generation of vacuum,the free gas and dissolved gas released from the water,and then through the automatic exhaust valve system,the water re injection system.These low water volume of water is unsaturated water and is highly absorbent of gas,it will absorb gas system so as to achieve a balance between water and gas.Vacuum deaerator to repeat such a cycle every 20~30 seconds.Most gas of the system will be removed by adopting such circulation.

The configuration of Vacuum degasser

Working process of Vacuum degasser

1.When the water pump is running,the water enters into the water inlet through sputtering mode. The water level of the tank is dropping to form vacuum state in the degassing tank.

2.When the water pump is running,the water enters into the water inlet through sputtering mode.The gas is separated from the water and exhausted through the vent valve because of negative pressure.The water level of the degassing tank is dropping continuously.

1.When the water level of the degassing tank drops to the alarm level,the water pump will stop. The water enters into the water inlet continuously and the gas is removed.

2.After the setting time, the water pump is turned on and continues to pump the vacuum.Then it will enter into the next operation cycle.

Functions of Vacuum degasser

The vacuum deaerator can remove the gas of the make up water and circulating water system,so as to protect the safe and stable operation of the equipment and system. Separating gas------it separates the free gas and dissolved gas of the system.

Technical characteristics of Vacuum degasser

1.Can greatly shorten the heating or cooling system for the first time after the initial injection of the exhaust time,is conducive to the initial commissioning of the system.

2.The vacuum deaerator can remove the gas from the system,reduce air resistance significantly and reduce energy consumption to ensure the reliability during the operation of the system.

3.Eliminate the pump cavitation,reduce system operation noise.

4.The time and cycle of the vacuum deaerator can be adjusted according to need.

5.The capacity of single equipment applicable system can reach up to 150 m3 and more than one set can be used in parallel.

6.The vacuum deaerator is equipped with terminal and has the function of remote control.

7.The vacuum deaerator can be used in any heating or cooling system to improve the performance of heat exchanger.

8.Because the type of the equipment is vacuum degassing and deoxidation, there is no secondary pollution problem.

9.The vacuum deaerator can slowly down the oxygen corrosion of pipe network,radiator and water pump significantly and prolong the service life of the system.

10.When the system runs normally,the equipment can exhaust the gas resulted from the leakage of pipe network and the make up water of the system with non-stop to keep stable operation of the system.

11.The vacuum deaerator can eliminate the small bubbles attached to the surface of the heat exchanger to improve the heat changing efficiency.

12.The vacuum deaerator is small in size and saves space.The installation is easy with flexible installation location and it is convenient for maintenance.The equipment runs automatically with safe and reliable performance.

Application of Vacuum degasser

1.All closed water circulation system

2.All kinds of heat supply and cooling system water circulation system

3.Central heating system

4.Heating and cooling system of capillary network

5.Central air conditioning system

6.Adopting the system of steel radiator

7.Greenhouse circulatory system

8.Floor heating system

9.Circulating water system of boiler heating

10.Circulating water system of deoxidation

11.Heating and cold supply system of hotel,hospital,public venue and office building etc.

12.Circulatory and closed system of heating and cooling for liquid process of factories

Technical parameters of Vacuum degasser

1.Holding water quantity of single equipment applicable system:≤150m3

2.Working temperature: 1~90℃

3.Ambient temperature: 1~40℃

4.Temperature of applied medium:0-90℃

5.Power supply:380V/50Hz

6.Maximum operating pressure:16bar

7.Protection grade of equipment:IP54

8.Working environment humidity:<95%,no condensation

9.Remove rate of free gas:99%

10.Remove rate of dissolved gas:90%

11.Operation mode:full-automation/timing automation/manual operation.Three modes can be switched for operation.

12.Applicable system:cooling system,cold and heating supply system and heating supply system.

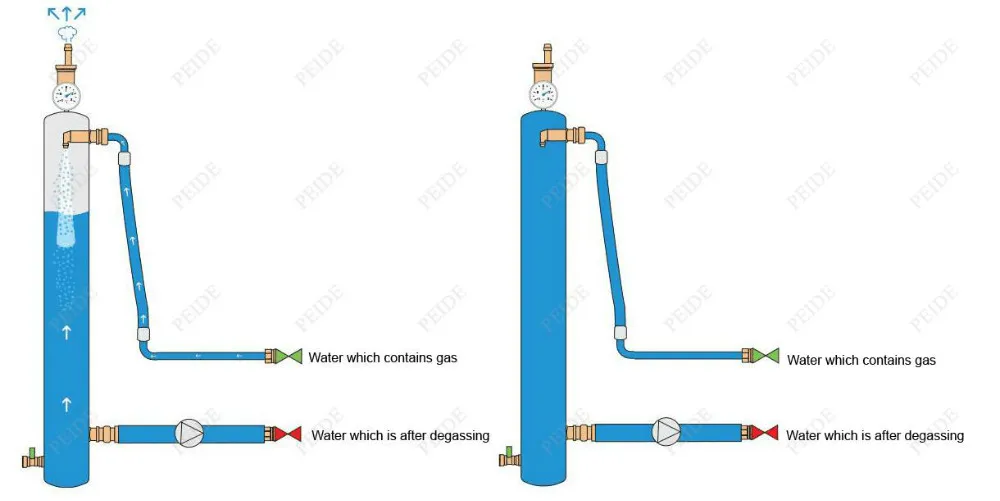

Model Coding of Vacuum degasser

Table of specification and dimension of Vacuum degasser

Model |

Maximum working pressure(Mpa) |

Setting Rang (Mpa) |

Power (Kw) |

Length (mm) |

Width (mm) |

Height (mm) |

Weight (Kg) |

PD-TJ1-1-20 |

1.0 |

0-0.25 |

0.55 |

600 |

500 |

1460 |

68 |

PD-TJ1-1-40 |

1.0 |

0-0.40 |

0.75 |

600 |

500 |

1460 |

71 |

PD-TJ1-1-50 |

1.0 |

0-0.50 |

0.75 |

600 |

500 |

1460 |

71 |

PD-TJ1-1-60 |

1.0 |

0-0.60 |

1.1 |

600 |

500 |

1460 |

73 |

PD-TJ1-1-70 |

1.0 |

0-0.70 |

1.1 |

600 |

500 |

1460 |

74 |

PD-TJ1-1-90 |

1.0 |

0-0.90 |

1.5 |

600 |

500 |

1460 |

80 |

PD-TJ1-1-120 |

1.6 |

1-1.20 |

1.5 |

600 |

500 |

1460 |

81 |

PD-TJ1-1-140 |

1.6 |

0-1.40 |

2.2 |

600 |

500 |

1460 |

87 |

PD-TJ1-1-190 |

2.5 |

0-1.70 |

3.0 |

600 |

500 |

1460 |

97 |

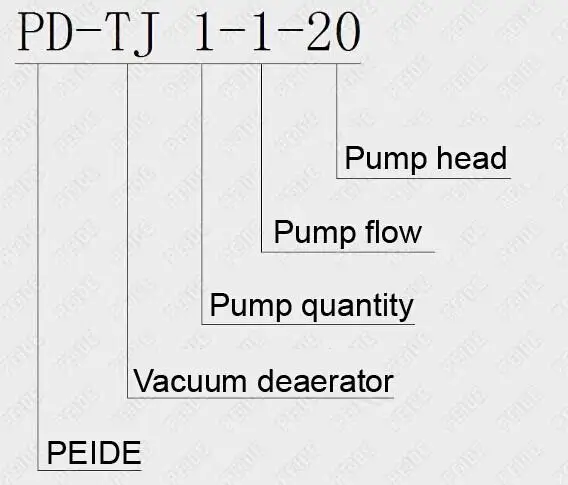

Installation notes of Vacuum degasser

1.The vacuum deaerator must be installed on the return line of heating supply and cooling system. The point of the installation shall be within the range of working pressure and its water temperature shall not exceed 60℃.

2.If the vacuum deaerator is installed in the heating supply system,the distance between installation location and highest point of the system shall not less than 15 m.While the vacuum deaerator is installed in the cooling system,the distance between installation location and highest point of the system shall not less than 5 m.

3.Please install the vacuum deaerator in the ventilated and dry position.

4.The equipment shall connect to the power source of 380V/50-60Hz.

5.Please confirm that the equipment shall be equipped with suitable constant pressure and expansion system and the fluctuation within a narrow range of system pressure will be caused by the water when the water comes in and out the vacuum deaerator.

6.The overpressure protection valve must be installed in the system to prevent the system from excessive pressure.

Installation diagram of Vacuum degasser

Site pictures for some cases of Vacuum degasser

Case scene 1 of Vacuum degasser :

Application:degassing of circulating chilled water and hot-water system of central air-conditioning Client: Wanda Plaza Core advantage:The degasifying effect of vacuum deaerator developed and produced by Peide Water Treatment Equipment Co.,Ltd. has reached up to 99% with automatic operation and the equipment is reliable and stable. Introduction to the vacuum deaerator:The operating pressure of the system is 0.67 Mpa and the water capacity of system is 102 m3.During the initial operation stage,the average operating time is 15 hours/ day in one month.After the first month,the average operating time is 2-3 hours/ day. The sound of water flow is much louder at the beginning.But the sound of water flow will disappear after one month. Project overview:The heating area of one commercial plaza is 42,000m2.From first floor to third floor,it’s used for shopping;the fourth floor is used for catering;the fifth floor is used for cinema.

Case scene 2 of Vacuum degasser :

Application:Heating system of the building Client:One Grade III,Class A Hospital in Beijing Core advantage:The degasifying effect of vacuum deaerator developed and produced by Peide Water Treatment Equipment Co.,Ltd. has reached up to 99% with automatic operation and the equipment is reliable and stable. Introduction to the vacuum deaerator:The operating pressure of the system is 1.15Mpa and the water capacity of system is 400m³.The average operating time is 15 hours/ day in the first one and a half month.After the first month,the average operating time is 3-5 hours/ day. The sound of water flow is much louder at the beginning.But the sound of water flow will disappear after one month. Project overview:The building area of the hospital is about 120,000 m2. Three vacuum deaerators are adopted and used in parallel.The equipments are installed in the machine room of the basement.

Case scene 3 of Vacuum degasser :

Application:Heating system Client:Park Hyatt Core advantage:The degasifying effect of vacuum deaerator developed and produced by Peide Water Treatment Equipment Co.,Ltd. has reached up to 99% with automatic operation and the equipment is reliable and stable. Introduction to the vacuum deaerator:The operating pressure of the system is 0.95Mpa and the water capacity of system is 180m³.During the initial operation stage,the average operating time is 15 hours/ day in one month.After the first month,the average operating time is 3-4 hours/ day. The sound of water flow is much louder at the beginning.But the sound of water flow will disappear after one month. Project overview:The hotel has 180 deluxe rooms in which there are 42 suites and 12 villas.The minimum room area is 65m2.The meeting space of banquet hall is 258m2.There are multipurpose activity spaces.

Case scene 4 of Vacuum degasser :