Brand Name: Peide Filters With Eletronic Controlers

Model Number: XLQ Filters With Eletronic Controlers

Place of Origin: Jiangsu, China (Mainland)

Industrial Self cleaning Filters With Eletronic Controlers

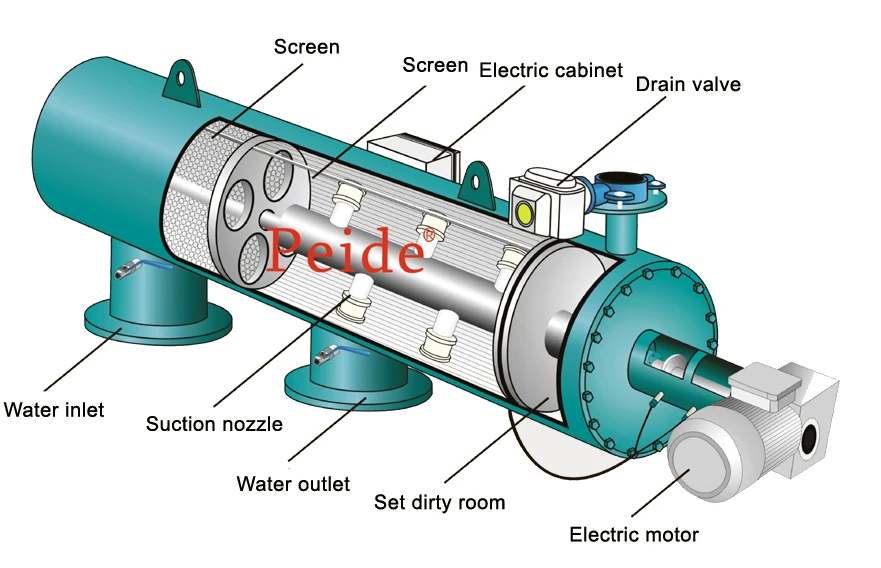

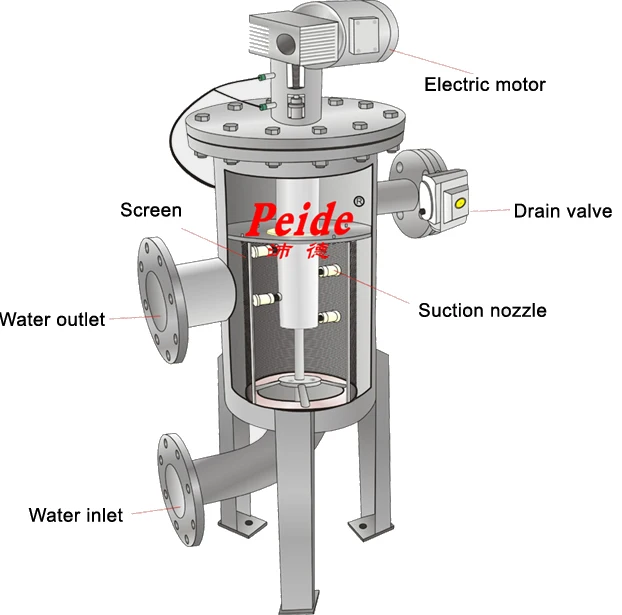

How Works

The unit consists of two stages of filtration, a coarse pre-filter and a stainless steel fine screen. The unwanted solids accumulate on the inner surface of the fine screen, building up a filter cake, which filters out even finer particles, creating a pressure differential. Once the pressure drop reaches a preset level, a rinse cycle is activated by the factory supplied control system. The solids are removed from the fine screen using a spot backwashing method, which aggressively sucks the dirt off the screen, similar to a vacuum cleaner, and are carried to the drain via the rinse valve. The dirt collector rotates, ensuring the entire screen is cleaned each cycle. The process takes a matter of seconds, without interruption of system flow.

Filters With Eletronic Controlers Control method

Filter has differential switch and integrator. Once the pressure drop reaches a preset level, a rinse cycle is activated by the PLC controller.

Filters With Eletronic Controlers Feature

structure compact low water consumption fine filter degree low pressure drop

Filters With Eletronic Controlers Application

1.Chilling water treating: such like cooling tower, water supplement system, air conditioning system, heat exchange system.

2.Raw water treating: such like surface water, lake, sea water, tank water, well to remove grind, sand, algae, organism etc.

3.Cycling industry water: cooling tower, polishing process water, ion exchange water, spraying process water, heat exchange plant, rolling plant, casting plant etc.

4.Irrigation: farm, dip field, golf, lawn etc.

5.Recycle water

Filter degree

Mic um |

100 |

120 |

150 |

200 |

400 |

800 |

1500 |

3000 |

Mesh |

150 |

120 |

100 |

80 |

40 |

20 |

10 |

5 |

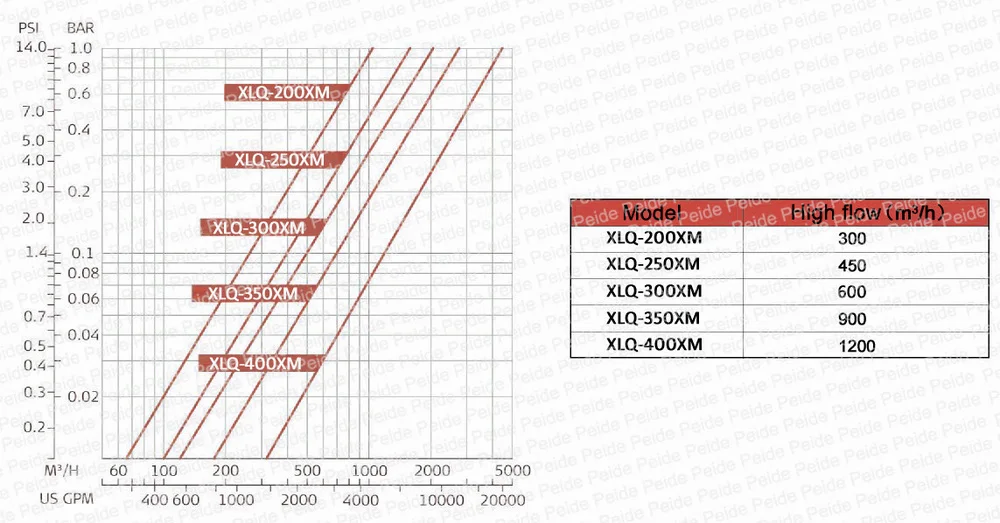

Filters With Eletronic Controlers type

| Model | In and out diameter(mm) | Flow rate(T/H) | Filter area(cm2) | Drain(mm) | Water consumption(L) | Motor(Kw) | Weight(KG) |

| XLQ-50XM | 50 | 20 | 1500 | 50 | 75 | 0.55 | 85 |

| XLQ-80XM | 80 | 50 | 1500 | 50 | 75 | 0.55 | 87 |

| XLQ-100XM | 100 | 80 | 3000 | 50 | 150 | 0.55 | 210 |

| XLQ-125XM | 125 | 100 | 3000 | 50 | 150 | 0.55 | 212 |

| XLQ-150XM | 150 | 150 | 7000 | 50 | 150 | 0.55 | 220 |

| XLQ-200XM | 200 | 300 | 7000 | 50 | 150 | 0.55 | 220 |

| XLQ-250XM | 250 | 450 | 11000 | 80 | 400 | 0.55 | 395 |

| XLQ-300XM | 300 | 600 | 11000 | 80 | 400 | 0.55 | 405 |

| XLQ-350XM | 350 | 900 | 13500 | 80 | 400 | 0.55 | 625 |

| Install way | Horizontal |

| Unit capacity | 15-900T/H,Achieve parallel install to achieve big capacity |

| Min work pressure | 0.25Mpa |

| Max work pressure | 1.0Mpa,1.6Mpa |

|

Filter precision

|

100-3000um |

| Control way | Differential pressure, time and manual |

| Max temperature | 65℃ (reach to 100℃ if required) |

| Back wash time | 50-90S |

| Rotating speed | 14-20rpm |

| Clean way | Scanning type |

| Differential pressure in cleaning | 0.01-0.08Mpa |

| Back wash water consumption | Approximate 280-310L |

| Voltage | AC220V 380V,50Hz,3PH,CONTROLLER: 220V |

| Motor power | 0.37Kw |

| Material | Carbon steel with anti-corrosion painting |

| Screen | Multi stainless steel mesh + pvc structure |

| Drain valve | cast iron with anti-corrosion painting |

| PLC controller | |

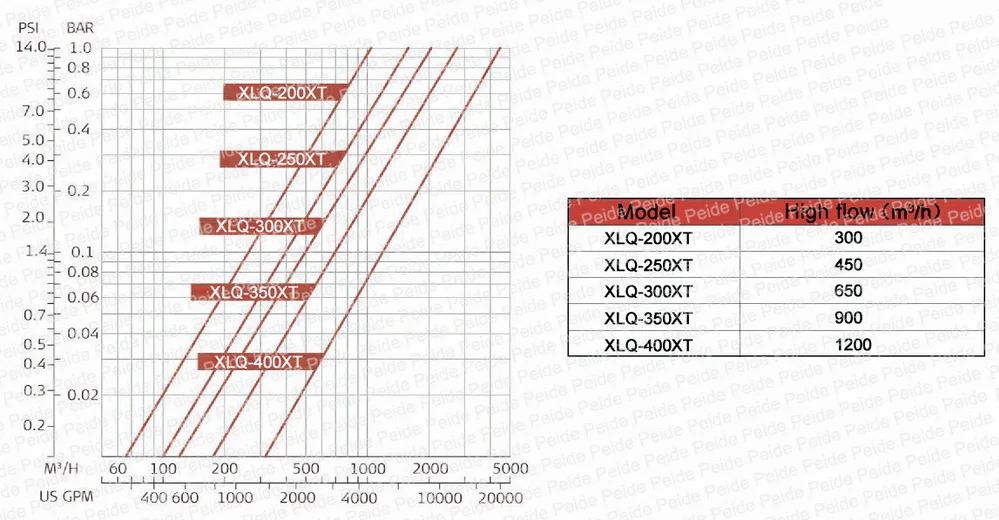

Pressure drop VS flow rate

Filters With Eletronic Controlers Verticaltype

| Model | In and out diameter(mm) | flow rate(T/H) | Filter area(cm2) |

Drain(mm) | Water consumption (L) |

motor(KW) | weight(KG) |

| XLQ-200XT | 200 | 300 | 7500 | 50 | 250 | 0.55 | 340 |

| XLQ-250XT | 250 | 450 | 11000 | 80 | 400 | 0.55 | 350 |

| XLQ-300XT | 300 | 650 | 11000 | 80 | 400 | 0.55 | 365 |

| XLQ-350XT | 350 | 900 | 13800 | 80 | 400 | 0.55 | 630 |

| XLQ-400XT | 400 | 1200 | 13800 | 80 | 400 | 0.55 | 650 |

| XLQ-350XT | 350 | 1500 | 13800 | 80 | 400 | 0.55 | 690 |

| Install way | Vertical installation |

| Unit capacity | 15-900T/H, Achieve parallel install to achieve big capacity |

| Min work pressure | 0.25Mpa |

| Max work pressure | 1.0Mpa,1.6Mpa |

|

Filter precision

|

100-3000um |

| Control way | Differential pressure, time and manual |

| Max temperature | 65℃ (reach to 100℃ if required) |

| Back wash time | 60-120S |

| Rotating speed | 14-20rpm |

| Clean way | Scanning type |

| Differential pressure in cleaning | 0.01-0.08Mpa |

| Back wash water consumption | Approximate 500L |

| Voltage | AC220V 380V,50Hz,3PH,Controller: 220V |

| Motor power | 0.37Kw |

| Material | Carbon steel with anti-corrosion painting |

| Screen | 316SS (Woven, ,multi-layer sintered, wedge) |

| Drain valve | cast iron with anti-corrosion painting |

| PLC controller | |

Pressure drop VS flow rate