Brand Name: peide, Peide

Model Number: CLDC-D

Place of Origin: Jiangsu, China (Mainland)

Application

The electric descaler widely used in central air conditioning system, industry chilling system, heat exchange system, boiler system, etc.

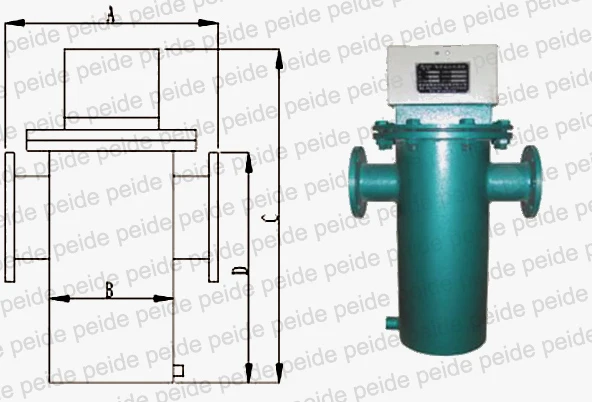

Product structure

It consists of main and vice part, which can be installed together or separated. Main part is a high-frequency signal generator, vice part can transfer signal to water.

Working principle

1. scale resist and prevent

Based on Electromagnetic Theory, invented by Dr. Lorentz, the electric water descaler stops calcium carbonate and magnesium carbonate formation. Water absorbs electromagnetic energy, which physical structure changes and chain water molecules break into smaller single water molecule. The single water molecule covers negative and positive ion of dissolve saline, which reduces electrostatic attraction and effective collision, but increase water dipole moment and compatibility to negative and positive saline, which finally loose pipe wall scale and to remove them.

2.kill bacterial and algae

The electromagnetic wave creates turbulence flow, which destroys cell wall’s ion channel and changes cell’s living ambient. Cells die as of no suitable living area. What’s more, large amount of single water molecules covers dissolve oxygen, which cut microorganism oxygen demanding so that to prevent microorganism sediment formation.

3. rust resist and corrosion prevention

Oxygen molecule in water become inert oxygen as covered by singe water molecule, which cut off oxygen-demanding for mental rust.

The electromagnetic field create “Skin-effect”, which gathers negative charge inside pipeline wall. Water molecule covers positive charge, it rejects Fe ion dissolve from metal pipe. Negative charge on pipeline wall attract positive Fe ion to form Fe3O4 membrane.

Pictures

Feature

1.Make use of high-frequency electromagnetic technology in water treating, which can increase at least 30% work efficiency.

2.The technology can treat max water hardness of 700mg/L. ( in CaCO3)

3.The special alloy material can make use life time to 20years.

4.Signal light shows electrode energy release enough or not.

5.Extra add drain outlet, which is easy to drain scales.

Technical parameter

1.Input power: 220V, 50HZ

2.Water hardness require: ≤700mg/L(CaCO3)

Temperature: ≤95℃

Work pressure: 1.0MPa,1.6MPa

Flow speed: ≤2.8m/s

3. Scale resist: ≥95%

Bacterial killing: ≥95%

Algae removing: ≥95%

Reduce corrosion: reduce to 1/10 of origin

4. Function time: within 2 hours in after treating. Half-time is 1 hour.

Compare

| No | Item | Made by PEIDE | Made by others company | Instruction |

1 |

Shielding mesh

|

Shielding mesh makes sure electrodes work separately, without any interruption |

No shied mesh |

Increase efficiency 30% |

| 2 | Electrode material | Alloy material | Brass | Life time 5-7times than brass |

| 3 | Circuit board and electrode connection way |

Makes use of shielding connection, it can transfer energy to electrodes fully |

Connect directly, which will cause dis-connect after long using. No shielding design, which has interruption to other equipment. |

Peide reduce the energy consumption to the lowest |

| 4 | In/outlet design | Add extra guide plate | No | Peide design can transfer more stable electromagnetic energy |

| 5 | Transformer material | Transformer works well even in severe ambient, (even in water) electric elements all imported | Less ability in high temperature and high humidity ambient. | Peide design can install indoor or outdoor |

| 6 | Protection setting on main part | The special temperature design can ensure main part work less than 40℃. | Over 50℃ | Main part life time increases 3-5times. |

| 7 | Drain design | Yes | No | Peide design more completed. |

| 8 | Vice part inside treating | With phosphorization treating | No | Increase strength of magnetic field. |

CLDC-D multi-function Electric Water Descaler

Model options

| Model | Pipe diameter | A | B | C | D | Power |

Water Flow |

|

| inch | mm | W | T/H | |||||

| CLDC-2D | 2 | 50 | 500 | 100 | 280 | 300 | 25 | 19 |

| CLDC-2.5D | 2.5 | 65 | 500 | 100 | 280 | 300 | 25 | 28 |

| CLDC-3D | 3 | 80 | 500 | 150 | 330 | 300 | 50 | 50 |

| CLDC-4D | 4 | 100 | 500 | 150 | 330 | 300 | 50 | 80 |

| CLDC-5D | 5 | 125 | 600 | 219 | 340 | 400 | 70 | 125 |

| CLDC-6D | 6 | 150 | 680 | 273 | 350 | 400 | 70 | 180 |

| CLDC-8D | 8 | 200 | 800 | 325 | 470 | 500 | 80 | 320 |

| CLDC-10D | 10 | 250 | 850 | 377 | 530 | 550 | 120 | 490 |

| CLDC-12D | 12 | 300 | 920 | 426 | 560 | 600 | 210 | 710 |

| CLDC-14D | 14 | 350 | 970 | 478 | 560 | 650 | 250 | 1000 |

| CLDC-16D | 16 | 400 | 1020 | 530 | 660 | 700 | 330 | 1400 |

| CLDC-18D | 18 | 450 | 1090 | 630 | 730 | 750 | 410 | 1600 |

| CLDC-20D | 20 | 500 | 1200 | 720 | 830 | 800 | 500 | 1970 |

CLDC-A multi-function Electric Water Descaler

Model options

| Model | Pipe diameter | A | B | C | D | Power |

Water Flow |

|

| inch | mm | W | T/H | |||||

| CLDC-2A | 2 | 50 | 400 | 159 | 760 | 580 | 25 | 19 |

| CLDC-2.5A | 2.5 | 65 | 400 | 159 | 760 | 580 | 25 | 28 |

| CLDC-3A | 3 | 80 | 400 | 159 | 760 | 580 | 50 | 50 |

| CLDC-4A | 4 | 100 | 400 | 159 | 760 | 580 | 50 | 80 |

| CLDC-5A | 5 | 125 | 460 | 219 | 760 | 580 | 70 | 125 |

| CLDC-6A | 6 | 150 | 520 | 273 | 780 | 600 | 70 | 180 |

| CLDC-8A | 8 | 200 | 560 | 325 | 820 | 640 | 80 | 320 |

| CLDC-10A | 10 | 250 | 610 | 377 | 860 | 680 | 120 | 490 |

| CLDC-12A | 12 | 300 | 710 | 478 | 960 | 780 | 210 | 710 |

| CLDC-14A | 14 | 350 | 770 | 530 | 1020 | 840 | 250 | 1000 |

| CLDC-16A | 16 | 400 | 910 | 630 | 1120 | 940 | 330 | 1400 |

| CLDC-18A | 18 | 450 | 1040 | 720 | 1220 | 1040 | 410 | 1600 |

| CLDC-20A | 20 | 500 | 1140 | 820 | 1330 | 1150 | 500 | 1970 |

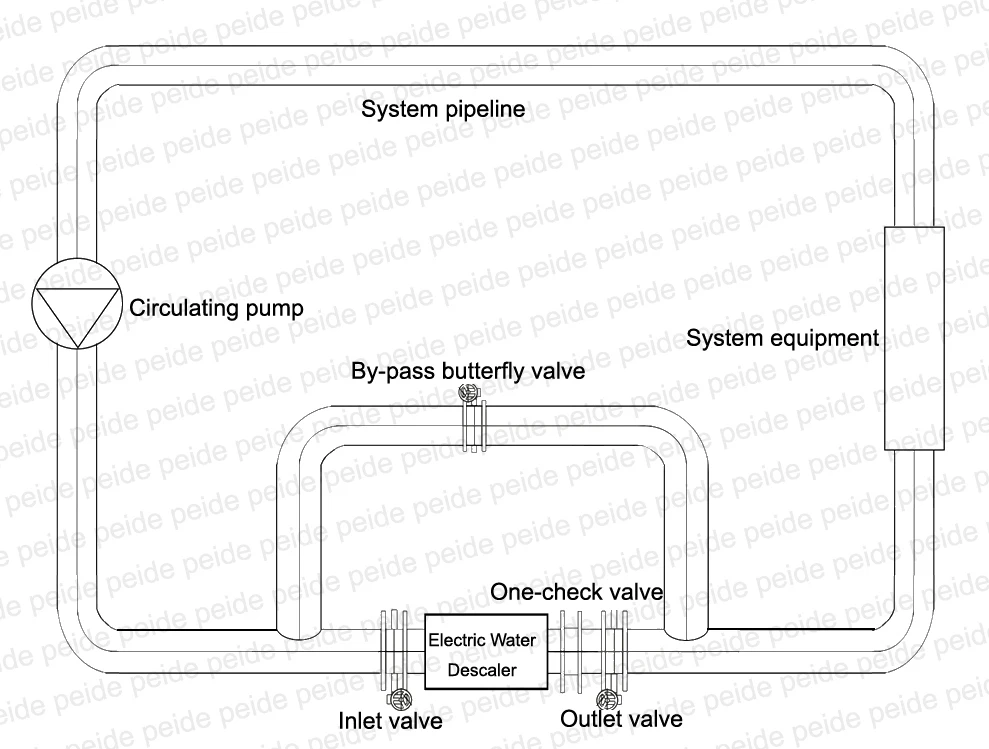

Install

Installation:

1.Power supply: According to technical parameters, AC200V,50Hz is required to use. There should be one time allowance power be supplied.

2.Position

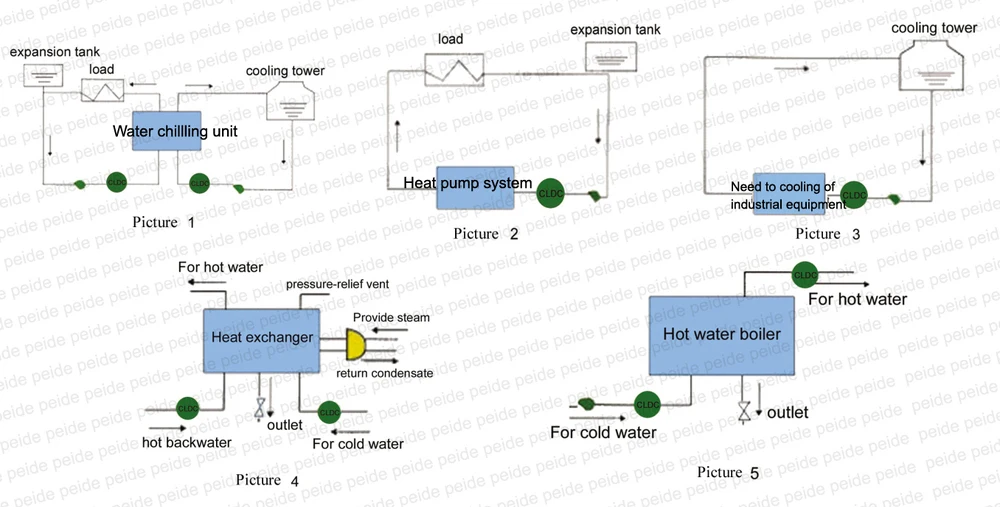

2.1 Chiller units in central air-conditions: installed at both pipeline of recycling cooling water and chilling water. See picture1

2.2 Heat pump unit in central air-conditions: installed at the pipeline of recycling cooling water . See picture2

2.3 Industrial cooling system: installed at a pipeline at where an equipment that need to be cooled. See picture3

2.4 Heat exchange system: installed both at hot backwater pipeline and cold water supply equipment. See picture4

2.5 Hot boiler system: installed at both cold water supply pipe line and hot water pipe line. See picture5

Attentions

1.Water equipment should be installed before equipment that need protect. It will be better to close to pump. All recycling water should flow into water treatment equipment fist.

2.If there’s no big default and scales on old system, water treatment equipment can be installed directly, or else, users should clean pipes’ scale first.

3.In central air-condition, before stop equipment working , users can add inhibitor help reduce corrosion on the equipment.

4.Rain proof and dirt proof device will be used, if the equipment is installed outside.

5. If pipe line is too long, users should make sure that there’s a water treatment equipment at a distance, so that the function will be much more better.

6. There should be a 300mm free space room for easy to repair. Make sure to inspect if there’s leak problem on the connections when equipment is finished installation.

7. When installed, the direction of flow rate should be the same as equipment. No reverse. Also drain valve and pipe need to installed at the drain.

8. Users not allowed to open the main frame. We will not in the charge of people death or hurt by high pressure Electricity.

How to use

-Red indicator light is the power indicator light.

-Green light is working indicator light.

-Red and green light is light on, it means equipment work Well.

How to deal with breakdown

Normally inspect according to the situation of red and green indicator light.

1)Red indicator light is the power indicator light. Green light is working indicator light.

2)Red light works, green light not work, users should stop the equipment, and notice the factory or technicians to repair.

3)Green light works, red light not work, it shows equipment in normal operation, users can notice the factory to repair at the same time.

Internal structure

Packing

Customers

Certificates

FAQ

Do you have certificates?

Yes , we have ISO / CE certificate and certificate of patent

Do you have design team?

We have a professional design team provide drawings, we wait for your confirmation and production

Can you guarantee delivery time ?

Timely transport, ensure the delivery time

Are you maufacturer ?

Yes, we are the professional water treatment equipment manufacturer in china