Brand Name: Peide

Model Number: BA01

Place of Origin: Jiangsu, China (Mainland)

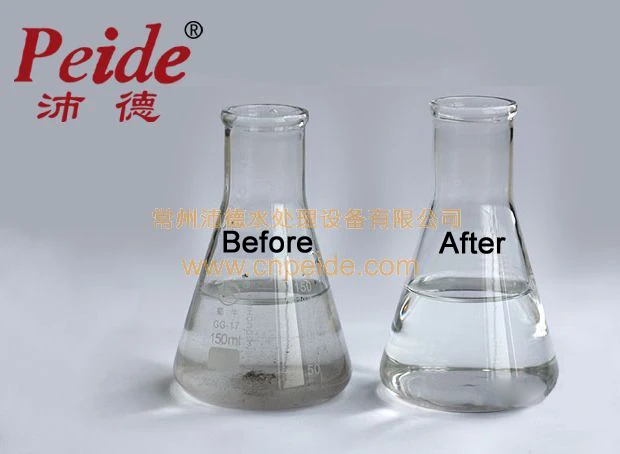

Working Principle

Bag filter is a widely used for liquid filtration,it can remove the particles of different size from liquid,in order to achieve liquid filtration,purification,separation,recovery purposes.It consists of three parts:bag housing,supporting basket and filter bags.According to flow rate,you may use multiple bags in a bag housing.First,the liquid enter into the housing from the inlet,which may placed in the side or on the top,and then flow into the filter bag which is braced by basket.Due to the impact pressure of fluid,the bag will extend and the liquid get evenly filtered through the bag and flow out of the outlet pipe.Impurities are trapped in the bag,the filtration process is complete.When you replace or clean the bag,just simply loosen the bolt,rotary hand wheel lifting the lid,and get the bag.

Characteristics

1,Unique design to prevent the bag sunk into basket under pressure,it ensure 100% no spills.

2,Rational allocation of seals on both single bag and multi-bag filter.It ensures t

he reliability of the sealing system.We can use ordinary steel ring sewn bag, or weld melt bag, to ensure no spill phenomenon.

3,Basket is made of perforated mesh, with molding, polishing, the impurities won’t stick with it.

4,A variety of optional material for basket, such as high-quality stainless steel SS304,SS316, we can also provide a variety of special metal filter container. Peide water treatment company provides economical filters, can provide users with a more affordable option.

5,Compact structure, reasonable size. Simple to install and operate, convenient, small occupation.

6,High filtration accuracy, for any fine particles or suspended matter, Range from 1 to 800 microns;

7,Unit filter area is large, a smaller filtration resistance, high filtration efficiency. A bag filter function is equivalent to 5-10 times of filter element of the same function,it can greatly reduce the cost; Range of flow rate: 1 ~ 1000m3 / h.

8.Extensive application:it can be used for coarse filtration, medium filter or fine filter.Compared with frame fine filter, cartridge filter, raw water pre-filter and fine filter and other devices,it is with low investment, longer lifetime and low operation cost, filter bag can be used repeatedly. 9.In the same reasonable structure, low operating costs, filter effectiveness and treatment capacity, the price is far lower than imported bag filter.

Specifications

1,Standard:GB, American Standard, German standard, Japanese standard, customized; single bag, parallel bag, multi-bag, cartridge;

2,Models: S, T series, PBF polypropylene containers etc.,

3 Rated flow: 6,10,23,51,,, 1088 tons / hour

4 Rated working pressure: 10, 20,, kg / cm2

5 Cylinder Material: 304 stainless steel (inside and outside blast or polished) or customized materials;

6 High-strength support basket: by uniform pore size of high-strength stainless steel mesh manufacture of 3.5mm;

7 Inlet and outlet: 1-14 or customized;

8 Inlet and outlet Location: Side into and side out, side into and bottom out,top into and bottom out, top into and side out or customized.

9 Interface Type: flange, screw thread or customized.

10 Bag model: and non-calibration;

11 Filtration precision: 1-800um (microns) relative or absolute precision;

12 Seal ring material categories: general nitrile rubber, Teflon, nylon, Te Fulong acid such as high temperature and high-performance specialty materials;

13 Type of bag: pure polypropylene, polyester, wool, viscose fiber, aromatic polyamide, Teflon, nylon and other materials;

14 Structure of bag: single screen (surface filtration structure, pore size of 100 to 800 microns), needle felt cloth (three-dimensional structure of fluffy deep filter, pore size of 1 to 200 microns) and melt blown nonwovens (deep bed filtration structure, pore size of 1 to 100 microns) three, and there are a variety of ~ 800 micron filtration precision to choose from, in order to meet the requirements of different production processes. Acid, high temperature and other characteristics of the bag material can be adapted to different filtered liquid chemical compatibility requirements.

Application

1 Food and beverage industry: beer, wine, wine, sake, liquor, wine,

fruit juice, bottled water, tea drinks, soy milk, syrup, dairy products, food additives, water filtration to clarify the process and CIP.

2 Petrochemical industry: all kinds of lubricants and oil, glue, chemical fiber manufacturing process of various solution was filtered.

3 Oil and gas industry: amine desulfurization, dehydration flux filter, oil field water, completion fluid filtration.

4 Car paint, painting industry: paint, electrophoretic paint, pre-treatment fluid, paint and paint raw materials and solvent filtration

5 Textile, printing and dyeing, paper making industry: spinning liquid, dyes, flux, water, additives, adhesives filter.

6 Edible oils and soap industry: polishing purification of edible oil, soap raw materials and water filtration.

7 Pharmaceutical industry: a variety of pharmaceutical intermediates, pharmaceutical raw materials, solvent filtration.

8 The electronic and electroplating industry: a variety of plating solution and water filtration.

9 Machining industry: a variety of cutting fluid, coolant and cleaning liquid filtration.

10 Other liquid filtration.

Since the bag filter using the company's products in Europe and America standard production, matching the imported materials, processing technology and standards of the bag, so that the user can ensure the accuracy of the final filter. Users can filter according to different needs, matching different shapes, different apertures, different structures and different material of the bag, in order to obtain the most economical and effective filtering effect.

Internal structure

1. Each bag has a separate locking device with no side leakage opportunities.

2. Integrated design of precision without distortion.

3. Integrated precision with lifting device.

4. O-ring seal, high-strength and quick bolts.

Application

Paint, Beer, Vegetable oil, Pharmaceuticals, Cosmetics, Chemicals, Petroleum products, Chemicals, Electroplating solution, Milk, Mineral water, Hot solvents, Latex, Industrial water, Coatings and paints, Sugar, Molasses, Resins, Inks, Industrial waste water, Juice, Cooking oil, Wax, Precision filters and other industries.

Parameter

Working pressure: 0.05MPa-0.6MPa

Working temperature: 5 ℃ -40 ℃ (special temperature can be customized)

Filtering Accuracy: 1μm-800μm

single bag Flow: 6.0 m3 / h-12.0 m3 / h

Operation mode: manual or automatic control

cylinder Material: 304,316L

Filter bag

1. Choose the imported high purified filament fiber material, singeing the surface of a special treatment to prevent pollution of the filtrate fiber shedding. Three-dimesional have a high ability to capture solids and colloidal particles. Hig-strength fiber has high filtration efficiency, stability and long life. Filter bag is produced on the standard of America production standard, GMP requirement and FDA requirement of domestic pharmaceutical industry.

2. Filter material: special withstand high temperature and acid polytetrafluoroethylene, PE, PP, nylon, NMO and so on. Stainless steel(SUS304) can reaches to filter percision from 0.5 to 1000 microns.

3. Bag collar: stainless steel ring, galvanized steel ring, PP, PE plastic ring and polyester rope.

4. The technical of filter bag welding is such as, plastic ring welding, seam welding and sewing the end including sewing, anti-seam and so on. We can supply the special filter bag based on customer’s requirement besides of supplying the industry standard filter bag (01#,02#,04#).

5. Filter basket: Filter equipment support the filter basket, one time machining molding. It has a circular cylinder high-strength slot in tube body.

Many bags filter parameter

Model |

Filter diameter |

Filter bag quantity |

Filter area |

Inlet and outlet diameter |

Treat liquid capacity(m3/H) |

Withstand pressure MPA |

DLQ02-2# |

φ400 |

2 |

1m2 |

DN80mm |

80 |

0.6-1.6 MPA |

DLQ03-2# |

φ500 |

3 |

1m2 |

DN100mm |

120 |

0.6-1.6 MPA |

DLQ04-2# |

φ600 |

4 |

2m2 |

DN125mm |

160 |

0.6-1.6 MPA |

DLQ05-2# |

φ650 |

5 |

2.5m2 |

DN125mm |

200 |

0.6-1.6 MPA |

DLQ06-2# |

φ700 |

6 |

3m2 |

DN150mm |

240 |

0.6-1.6 MPA |

DLQ08-2# |

φ800 |

8 |

4m2 |

DN200mm |

320 |

0.6-1.6 MPA |

DLQ10-2# |

φ1000 |

10 |

5m2 |

DN250mm |

400 |

0.6-1.6 MPA |

DLQ12-2# |

φ1000 |

12 |

6m2 |

DN250mm |

480 |

0.6-1.6 MPA |

DLQ16-2# |

φ1200 |

16 |

8m2 |

DN300mm |

640 |

0.6-1.6 MPA |

DLQ20-2# |

φ1400 |

20 |

10m2 |

DN300mm |

800 |

0.6-1.6 MPA |

DLQ24-2# |

φ1400 |

24 |

12m2 |

DN350mm |

1000 |

0.6-1.6 MPA |

Manufacturing Process

Customers

Certificates

FAQ

Do you have certificates?

Yes , we have ISO / CE certificate and certificate of patent

Do you have design team?

We have a professional design team provide drawings, we wait for your confirmation and production

Can you guarantee delivery time ?

Timely transport, ensure the delivery time

Are you maufacturer ?

Yes, we are the professional water treatment equipment manufacturer in china