Brand Name: --

Model Number: --

Place of Origin: Jiangsu, China (Mainland)

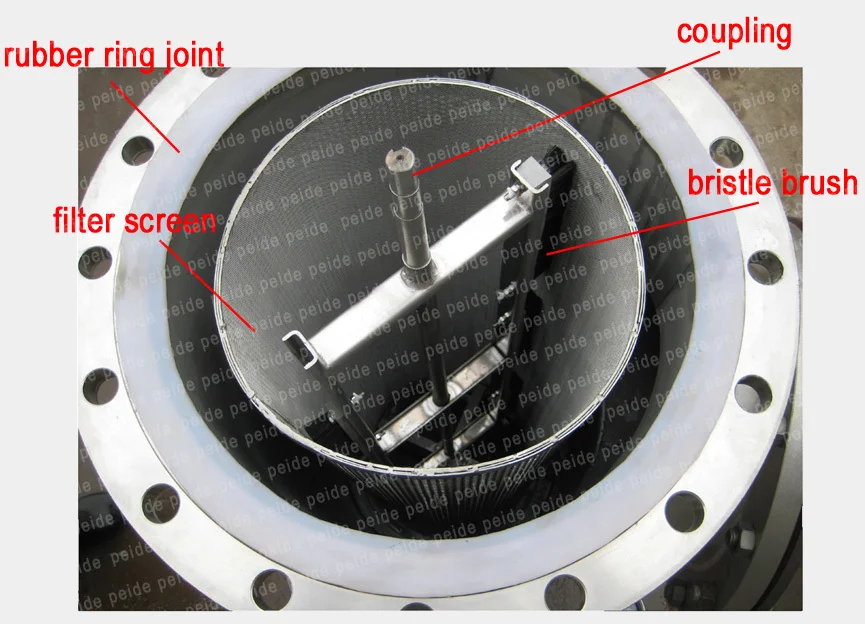

Structure and working principle

Automatic brushaway filter is composed of the drive mechanism, the control circuit (including the pressure switch), filter components, cleaning device, connecting flanges and other major component parts.It cleans sewage by the drive motor and the electric valve automatically, the operation mode is automatic operation (option:manual operation), with timing control or pressure difference control. Its automated part is controlled by reliable PLC programmable controller.

Water enters into the filter, the mechanical impurities are intercepted.When the impurities accumulate for a period, reaches 0.05MPa, then the differential pressure switch will send signal, while the PLC command is issued, transmission motor starts, the drain valve opens, the impurities deposited on the filter is brushed away, and drain out. The whole process is without personnel, without downtime. Besides, the device also has the function of timing and manual cleaning to ensure that the outlet water is safe under any circumstances.

Two types of cleaning method

Automatic control: there are two types:timing control and pressure difference. Set the filtration time on the filter timer, when it reaches the setting time, the brush will start cleaning sewage,discharge time is also set by timer; while the system pressure control system with real-time user-defined pressure compared when the system pressure reaches the set pressure difference, the filter will start cleaning sewage, sewage discharge time set by the timer.The whole system returns to its initial state, prepare for the next filtration step.

Manual control: Press the manual button on the control panel, filters will start cleaning.

Feature

Filter precision from 100um to 3500um,big filter area,high sewage carrying capacity,customized product.

Simple turn-of-a-handle cleaning of the filter screen,adjust the parameter of the automatic cleaning system.Automatic cleaning.

Has motor overload protection, which can effectively protect the motor.

Eliminates the need for turning off the water and extracting the filter screen for rinsing.No interruption of the process water flow during cleaning,Low pressure loss:less than 1%.

Easy to maintenance,installation and disassemble.

Flange connections to the user’s pipeline, national standard flange, versatility.

Application

1. Heating system, hot water circulation system.

2. Central air conditioning, chillers, cooling and refrigeration chiller water circulation system.

3.Industrial and civil cooling water, process cooling water circulation system.

4.Hot water bath, heating circulation system.

To protect the cooling equipment, heat exchanger, air conditioners, boilers and so on.The device is suitable for a wide range of industries, including construction, chemical, electric power, metallurgy, rubber, paper, textile, coal, food and other industries.

Metallurgy: continuous casting water, high-pressure phosphorus in water, the net ring of water, muddy water filtration loop, cooling water full filter, next to the filter, nozzle protection

Electricity: turbine cooling water filtration, gray water recycling filtration, dust nozzle protection, cooling tower water filter and next to the filter, such as whole Raw water: lakes, rivers, reservoirs and water, well water, rainwater, groundwater extraction of sand, algae, organic filtration

Agriculture: irrigation, drip irrigation water

Other: construction, iron and steel, petroleum, chemical, electronics, power generation, textile, paper, food, sugar, pharmaceuticals, plastics, automotive industry, etc.

Widely used in drinking water treatment, construction circulating water treatment, industrial circulating water treatment, wastewater treatment, mining water treatment, water treatment and other areas of the golf course.

Technical Parameters

1. Treatment effectiveness

Filter precision: customized

Filtration efficiency: 99%;

Initial pressure loss: ≤0.015Mpa.

2. Inlet Water Quality

Working pressure: 1.0 / 1.6 / 2.5Mpa;

System pressure: ≥0.4Mpa;

Working temperature: 1 ℃ -90 ℃;

Working environment temperature: 1 ℃ -50 ℃;

Relative Humidity: <95%.

3. Operating parameters

Mean time between failures:> 60,000 hours;

Design life: 20 years for shell; 8 years for electrical parts.

Power: 0.2-0.6kw

Operating voltage: 220V ~ 380V ± 10%, 3-phase, 50 / 60Hz;

Safety insulation voltage: 5000V.

Size Chart

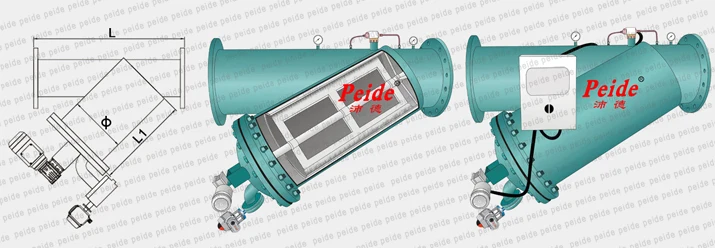

Y type automatic brushaway filter

| Model | Inlet&outlet | Max flow rate | dimension | drain | motor | ||

| mm | T/H | L | φ | L1 | mm | Kw/r/min | |

| SLQ-2Y | 50 | 19 | 600 | 159 | 300 | 25 | 0.18/1400 |

| SLQ-3Y | 80 | 50 | 600 | 159 | 300 | 25 | 0.18/1400 |

| SLQ-4Y | 100 | 80 | 700 | 159 | 300 | 40 | 0.18/1400 |

| SLQ-5Y | 125 | 125 | 750 | 219 | 350 | 40 | 0.18/1400 |

| SLQ6Y | 150 | 180 | 800 | 275 | 450 | 50 | 0.18/1400 |

| SLQ-8Y | 200 | 320 | 850 | 325 | 525 | 50 | 0.18/1400 |

| SLQ-10Y | 250 | 490 | 900 | 377 | 650 | 50 | 0.18/1400 |

| SLQ-12Y | 300 | 710 | 950 | 426 | 700 | 65 | 0.18/1400 |

| SLQ-14Y | 350 | 970 | 1170 | 478 | 820 | 65 | 0.18/1400 |

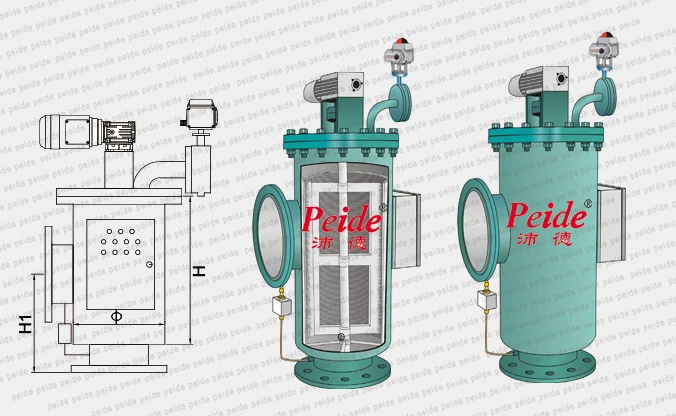

| Model | Inlet&outlet | Max flow rate | dimension | drain | motor | ||

| mm | T/H | L | φ | L1 | mm | Kw/r/min | |

| SLQ-2F | 50 | 19 | 300 | 159 | 225 | 25 | 0.18/1400 |

| SLQ-3F | 80 | 50 | 300 | 159 | 270 | 25 | 0.18/1400 |

| SLQ-4F | 100 | 80 | 300 | 159 | 300 | 40 | 0.18/1400 |

| SLQ-5L | 125 | 125 | 350 | 219 | 365 | 40 | 0.18/1400 |

| SLQ6F | 150 | 180 | 600 | 273 | 450 | 50 | 0.18/1400 |

| SLQ-8F | 200 | 320 | 700 | 325 | 560 | 50 | 0.18/1400 |

| SLQ-10F | 250 | 490 | 700 | 377 | 700 | 50 | 0.18/1400 |

| SLQ-12F | 300 | 710 | 1000 | 426 | 800 | 65 | 0.18/1400 |

| SLQ-14F | 350 | 970 | 1000 | 478 | 940 | 65 | 0.18/1400 |

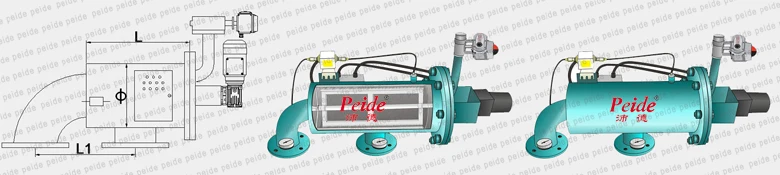

| Model | Inlet&outlet | Max flow rate | dimension | drain | motor | ||

| mm | T/H | L | φ | L1 | mm | Kw/r/min | |

| SLQ-2L | 50 | 19 | 300 | 159 | 250 | 25 | 0.18/1400 |

| SLQ-3L | 80 | 50 | 300 | 159 | 250 | 25 | 0.18/1400 |

| SLQ-4L | 100 | 80 | 300 | 159 | 250 | 40 | 0.18/1400 |

| SLQ-5L | 125 | 125 | 350 | 219 | 275 | 40 | 0.18/1400 |

| SLQ6L | 150 | 180 | 450 | 273 | 325 | 50 | 0.18/1400 |

| SLQ-8L | 200 | 320 | 525 | 325 | 360 | 50 | 0.18/1400 |

| SLQ-10L | 250 | 490 | 650 | 377 | 425 | 50 | 0.18/1400 |

| SLQ-12L | 300 | 710 | 700 | 426 | 450 | 65 | 0.18/1400 |

| SLQ-14L | 350 | 970 | 820 | 478 | 520 | 65 | 0.18/1400 |

Installation Points for attention

1, The check valve must be installed to avoid back pressure or backwater phenomenon, caused by inward deformation of filter screen.

2,For the operating pressure above 0.8MPa or more, the gate valve must be installed on the sewage lines, it will reduce the pressure loss, and the impact after the drainage. (you may ask for specific advisory from suppliers)

3,Pay attention to the mounting direction of the arrow, to prevent equipment damage due to installation error.

4,Prohibit the sudden pressure relief. For example, the normal working pressure is 1.3MPa, shut down suddenly,and open the outlet piping manifold pressure relief valve, it will have a huge opening moments of pressure will cause filter damage.

5, Make sure that the filter works within the normal operating range, banned from over pressure, over flow rate.