Brand Name: Hope Deepblue

Model Number: ZX-105

Place of Origin: Chongqing, China (Mainland)

500ton direct-fired LiBr absorption chiller

Cooling capacity:1050 kw

Heating capacity: 879 kw

Cold water: 12-7 ℃

Cooling water: 30-36 ℃

Hot water: 95-85 ℃

Weight: 11.1/14.8 ton

Dimension: 4640*2260*2350 mm

Direct-fired LiBr Absorption Chiller Product Features(Heater)

Working Principle

Direct-fired lithium bromide absorption chiller is a refrigeration equipment which uses natural gas,petrol,diesel,light oil,heavy oil,biogas etc.as its driving power.The LiBr solution is the circulated working medium,with LiBr as the absorbent and water as the refrigerant.

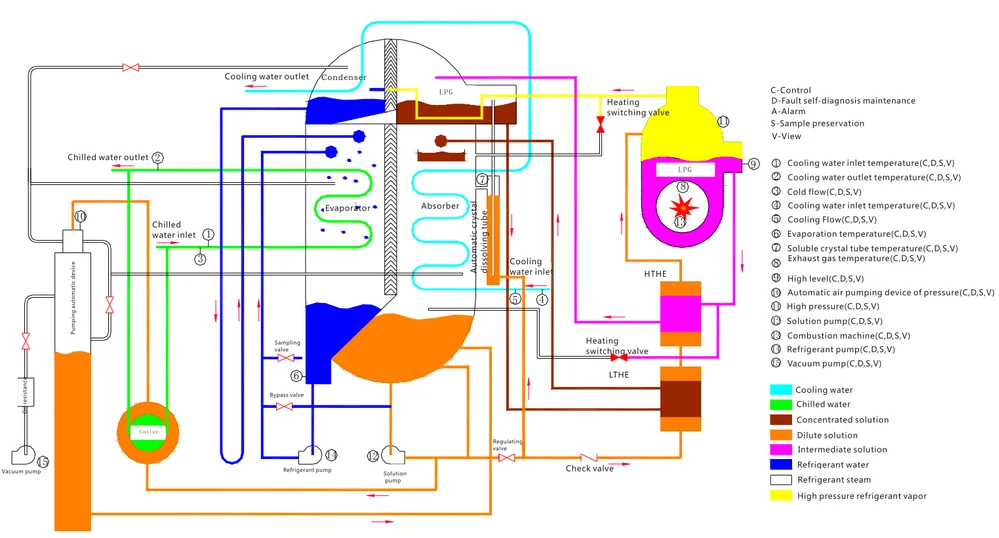

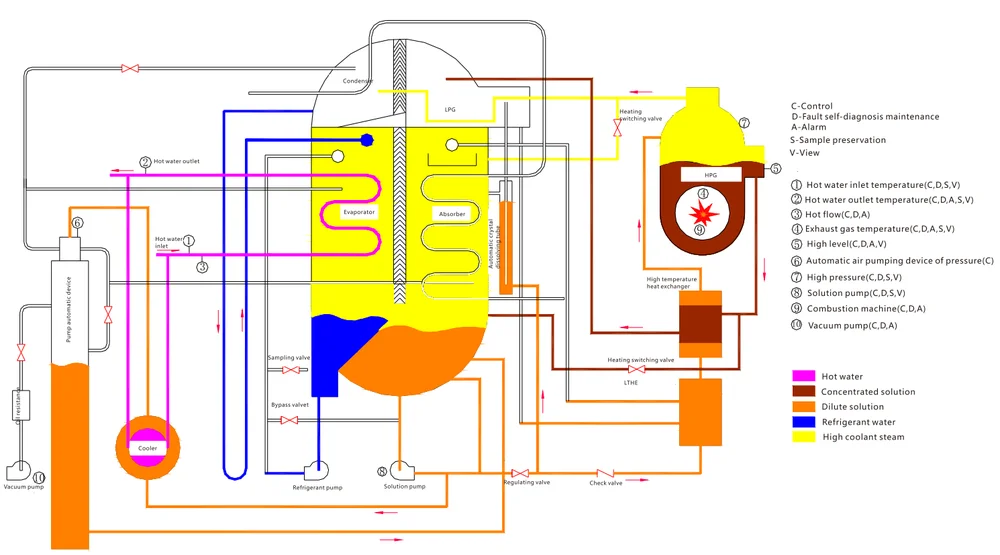

The units is mainly composed of the high-pressure generator(HPG),low-pressure generator(LPG),condenser,evaporator,absorber,high temperature heat exchanger,low temperature heat exchanger,automatic purge system,combustor,vacuum pump and canned pump.etc.

Cooling cycle

The diluted solution,transferred by the solution pump,through the low temperature heat exchanger,condensate water heat exchanger,high temperature heat exchanger heating after entering in the high-pressure generator.In the high-pressure generator,the diluted solution is heated by the flame there to generate high-tempetature refrigerant vapor,and then condensed into intermediate solution.The intermediate solution entered into the low-pressure generator though the high-temperature heat exchanger and is heated by the high pressure,high temperature refrigerant steam coming from the high pressure generator to generate the refrigerant vapor,and then further become concentrated solution.

The high-temperature refrigerant vapor(water) generated in the high-pressure-generator is heated the intermediate solution of the low-pressure generaor and then cooled into refrigerant water.The refrigerant water,after throttled,pressure reducing,with the refrigerant vapor generated in the low-pressure generaot entered into the condenser to be cooled by the cooling water,and become refrigerant water which is correspond with condensing pressure.

The liquid coolant of the condenser through the throttle,then enters the evaporator.Due to the low pressure of the evaporator,so that the refrigerant water in low temperature can evaporation boiling,when the coolant water is used pump for conveying,spraying in submerged tube evaporator is immediately,evaporation,absorption evaporator tube inner cooling water heat,so that the inner tube water temperature decrease,cheieve the purpose of refrigeration.

By the low pressure generator out of the concentrated solution flows through the low temperature heat exchanger into the absorber,sprayed in the evaporator made the evaporator evaporation process constantly.Due to absorbed the refrigerant vapor from the evaporator to become diluted solution,and them is transferred into the high pressure generator by the solution pump to boiling and concentrated.Thus completing a cooling cycle.

Heating cycle

The diluted solution heated and condensed bu the HPG generated the refrigerant vapor.Then the refrigerant vapor is directly trandferred into the evaporator and absorber.In the evaporator heat exchange,preparation of warm water.In addition,the absorption liquid is concentrated in to high concentrations entered into the absorber and mixed with the refrigerant water become the diluted solution,and then through the low temperature heat exchanger,low temperature heat exchanger to the high pressure generator.Through the above cycle,to achieve the warming.

Flow Chart ( Cooling cycle)

Flow Chart ( Heaating cycle)

Features:

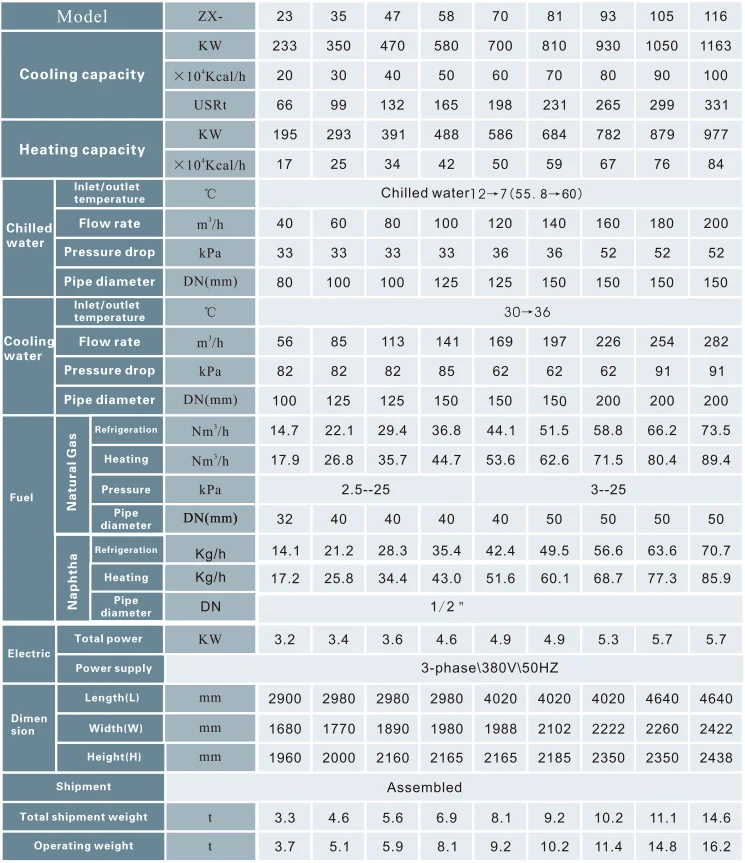

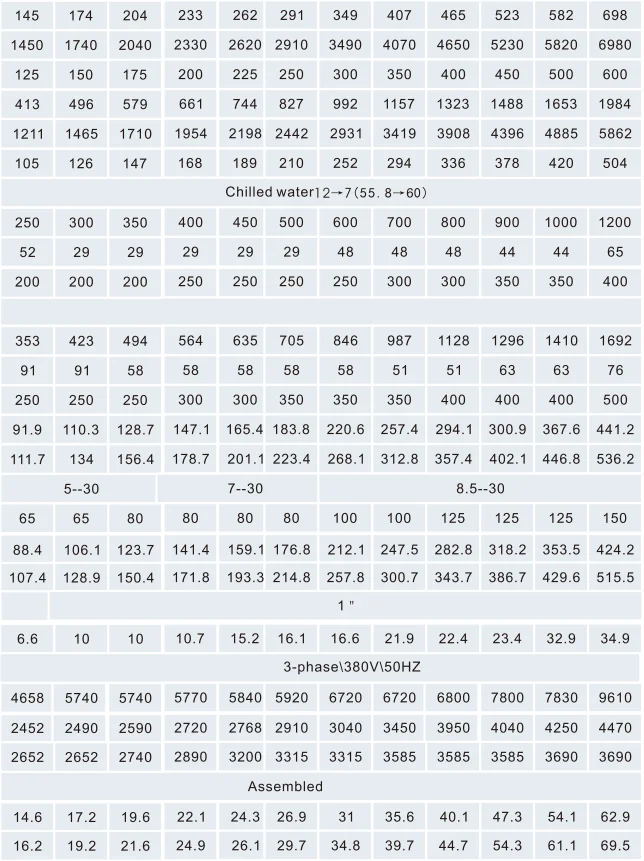

Specification:

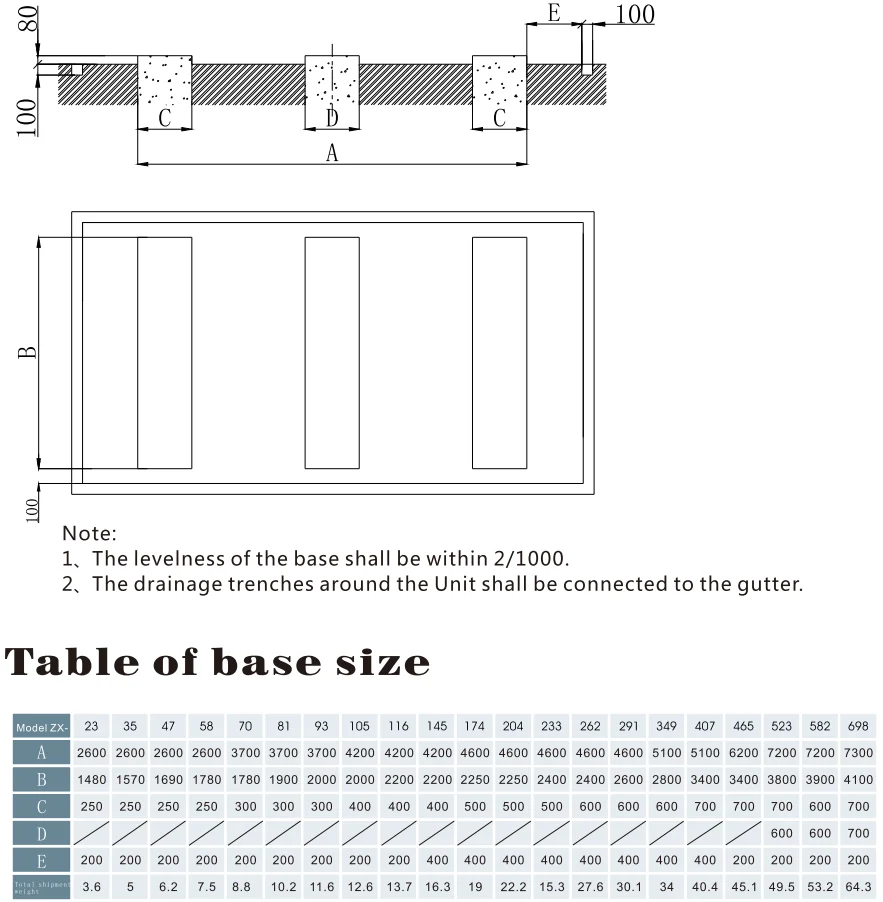

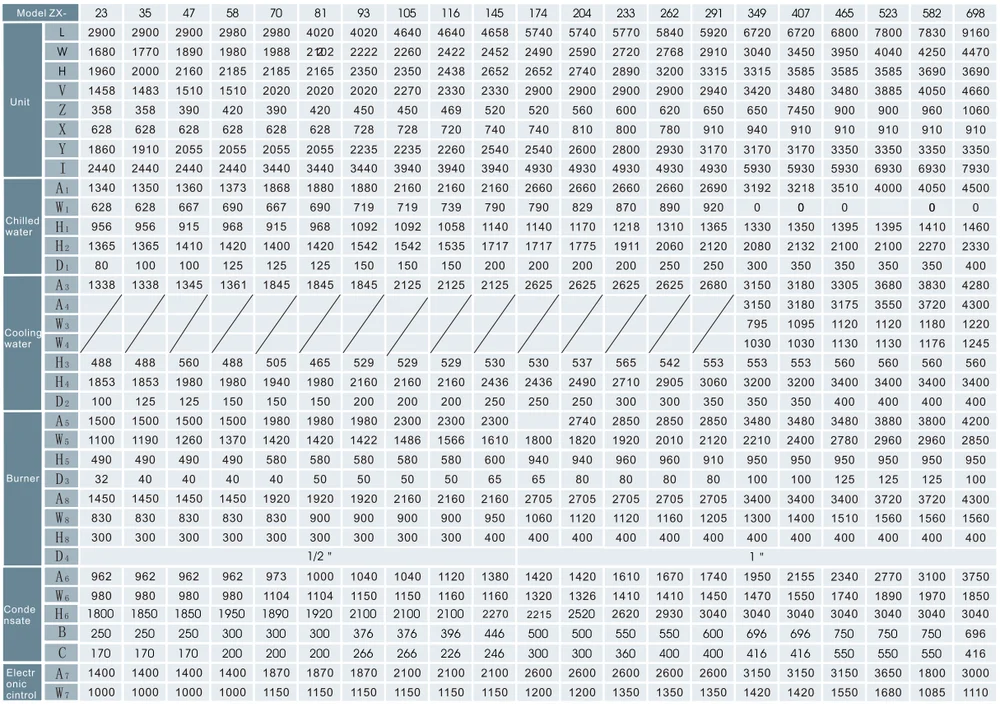

Dimension:

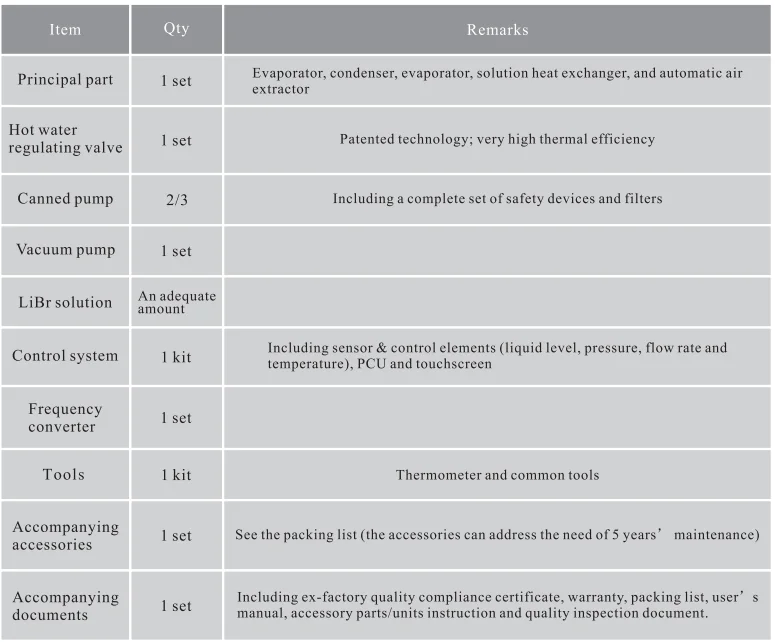

Scope of Supply :

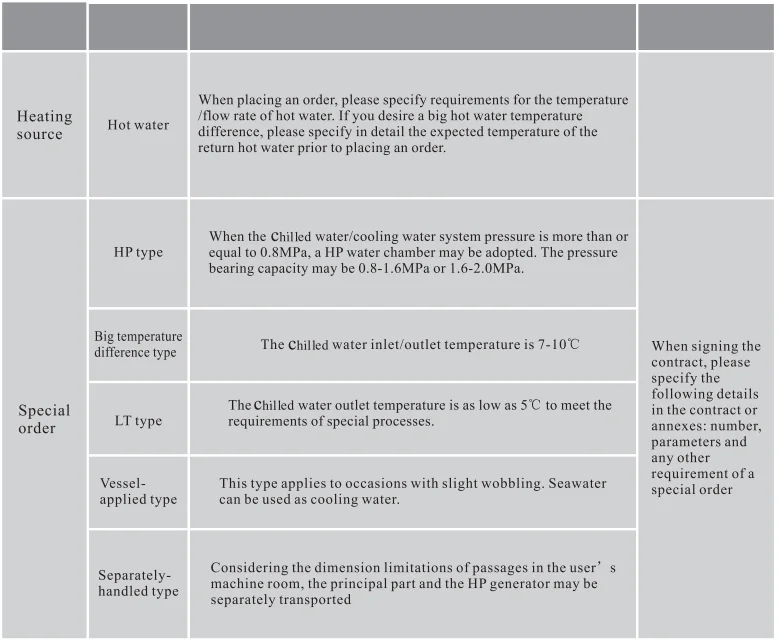

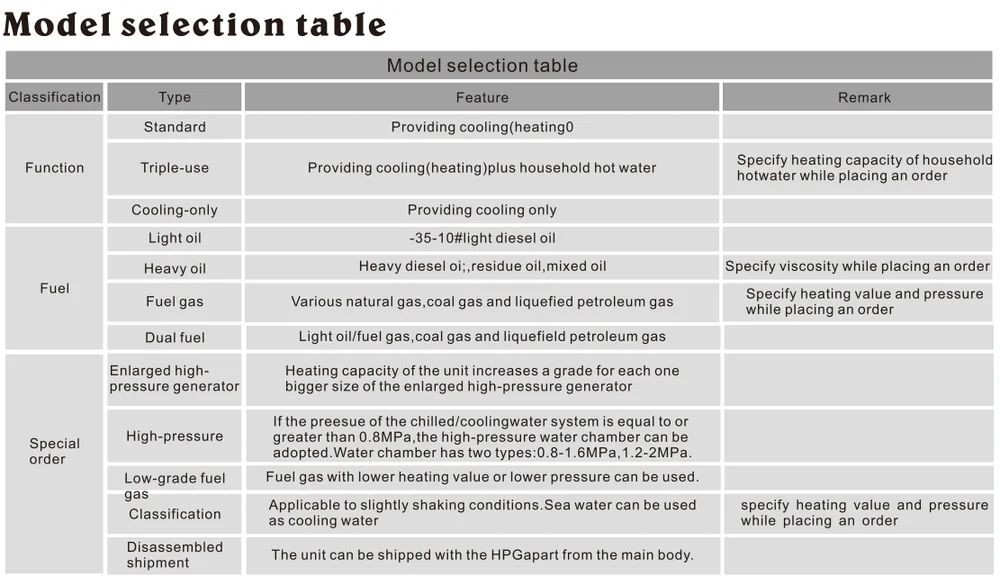

List of Models:

Quick Model-selecting Form:

Engineer available to service machinery overseas

Quality assurance lifetime: