Brand Name: TIANJIN COORIG,CHINA

Model Number: ADL-5-1500

Place of Origin: Tianjin, China (Mainland)

Product features:

A motor driven speed adjustable decoiler (Optional 8 or 10 tons of hydraulic decoiler)

The material frame being controlled by the independent speed adjustable converter motor

with the material processing saving mode ,users can reduce the waste of sheet metal significantly to

less than 20mm per material coiler.

With the feature of the servo motor driven in folding process and accurate positioning,it has the obvious

advantage especially when producing the shaped duct.

the input adopted two models:screen touch and keyboard which ensures stability of the system.

A servo motor driven material feeding and folding platform

The speed of each part can be adjusted as needed

With production management function for day count and total count

Support production data records export and print function (optional)

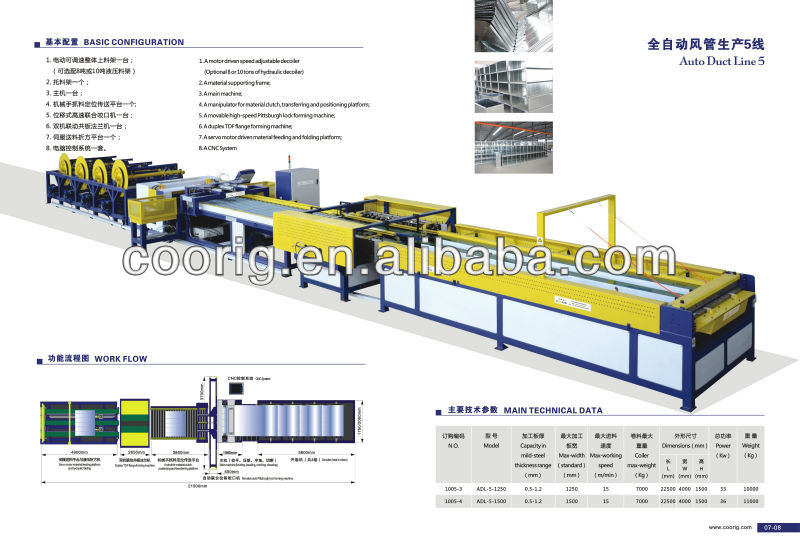

BASIC EQUIPMENTS:

A motor driven speed adjustable decoiler (Optional 8 or 10 tons of hydraulic decoiler)

Optional 8 tons or 10 tons of hydraulic material frame

A material supporting frame

A main machine

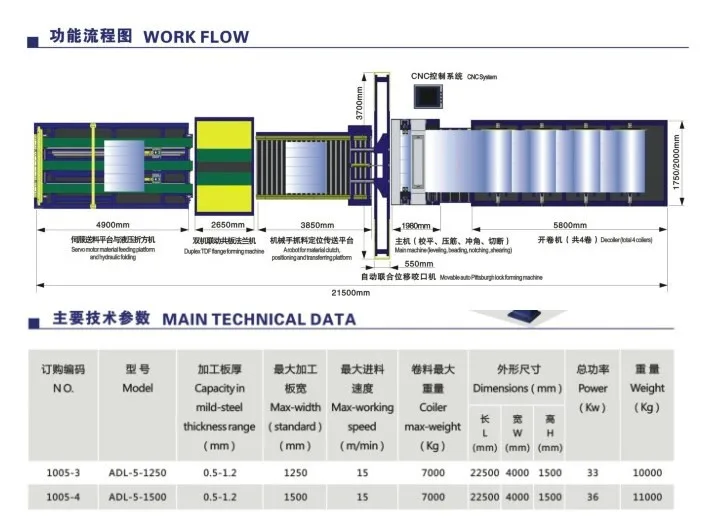

A manipulator for materil clutch,transferring and positing platform

A movable high-speed Pittsburgh lock forming machine

A duplex TDF flange forming machine

A servo motor driven material feeding and folding platform

A hydraulic folding machine

A CNC System and a set of production software

FUNCTION:

This line is mainly being used to complete the TDF flange ducts or drive cleat (optional), the production

capacity is 600 to 2000 square meters per day. After input the dimensions of the duct you want to process

and then the machine can complete the following functions:Uncoil,levelingbeading, notching and punching,

shearing,Pittsburgh locking,TDF flange forming/angle steel flange forming and hydraulic folding.

Optional 8 or 10 tons of hydraulic decoiler

PARTS: