Brand Name: Retek

Model Number: --

Place of Origin: Zhejiang, China (Mainland)

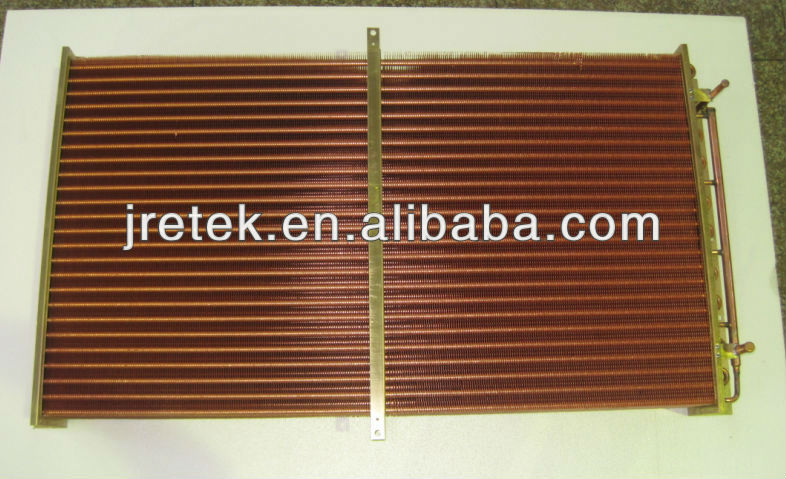

copper coil fin tube heat exchanger

Fin punched with flanging height 1.5mm, toroidal contact with aluminum tube, greatly increased heat exchange area.

- The al tube bended completely without any joint,then pulling the al-tube inside the fins by mould, more tight contact.

-With tube expansion system adopted, more tight contact between fins & tubes, heat exchange efficiency increased 40~60%

- Fin pitches can be free engineered as per cooling request

- Japan imported full automatic cleaning machine, super cleanness for R134a refrigerant

-Besides the evaporator main body without any brazing points, it highly reduces and avoids the risk of leakage.

Application: No-Frost Fin Evaporator is applied to different types of single door, double doors and multi-doors no-frost refrigerators. It is also can be used as evaporator or condenser for other refrigeration equipment.

]1.Main material:

Aluminum pipe (O.D8 to 0.D10) x (t0.7 to t1.0) (tube inner smooth or inner grooved)

Copper pipe: (O.D6 to O.C9.52) x (t0.36 to 0.5 tube inner smooth or inner grooved)

2.Structure:

Draw expanded type

Insert type

Side embedded type

Machine expanded type

Spiral finned type

3.Technical ability:

Fin specification for A type (L x W): 60 x 27mm, 77 x 27mm

Hole distance: 25mm

Fin specification for B type: width 50 or 60mm, holes array as the 11 x 19.05 (22 equilateral trangle shape)

Fin specification for D type: O.D9.52 copper tube

Hole distance 25 x 25mm (square shape)

Fin pitch: 4.2mm

4.Performance:

Surface anodic oxidiztion or dip coating to prevent the corrosion

Note: the inner grooved copper tube increases the heat exchange area and enhances the heat exchange performance

Jaslant insert type and spiral evaporator comparatively has the largest heat exchange area and enhances the heat exchange performance

Any interest , pls feel free to contact with us at any time .

Best Regards

VITO