Brand Name: LNEYA

Model Number: SUNDI-2A10W

Place of Origin: Jiangsu, China (Mainland)

Touch screen display precise temp. control 10 kw water air chiller -25~200 degree SUNDI-2A10W

Typical Applications

Reactor Systems Autoclaves

Pilot Systems

Mini Plant Systems

Scale up for Operational Development

Double wall reactors

Advanced-Flow Reactors

Distillation Systems

Material Testing

Combinational Chemistry

Semiconductor Industry

Vacuum Chambers

Advantages & Functions

Wide working temperatures

Previously unachievable performance

Intelligent temperature control

Maximum process stability and reproducibility

Adop plate heat exchager,Pipeline heating,the fastest heating and cooling rates.

High cooling power

Large temperature range without fluid change

Closed system,extend thermal fluid lifetime

Incredibly compact

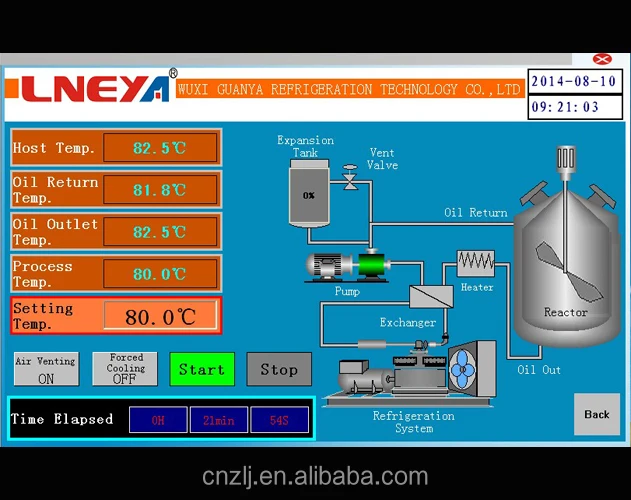

7-inch,10-inch color TFT touch screen display

Comprehensive warning and safety functions

Rapid cooling down from high temperature

Use magnetic drive pump,solve the circulation pump leakage

Structure design

The repeatability of temperature control result

Each cycle curve slope is consistent and greatly improve the consistency of the production thermostatically controlled environment. There is no overshoot occurred for reaction material and with fast and stable in the whole process.

The Refrigeration system's multi – image displays various information

1. Displays all the kind of process control temperatures.

2. Shows the liquid level of the heat conducting medium in the expansion vessel.

3. Shows indication for refrigeration system working.

4. Shows indication for heater working.

5. Shows indication for circulation pump working.

6. Displays the temperature control (materials temperature control pattern, heat conducting medium temperature control ).

7. The temperature upper limit, lower limit control can be set.

8. The temperature difference between jacket & reactor material can be set.

9. Shows the alarm to add the liquid when it is empty.

10. The refrigeration compressor can be set to operate manually or automatically.

Process control

Change the control settings of the method, the response as soon as possible in the process of the system lags behind, be the smallest system overshoot. Controlled by two PID (PID is a variable in each group) control loop structure, known as the two sets of control loops: the main circuit and from the circuit, the main control loop from the loop output as the settings.

System with feedforward with PV, the master PID loop operation results of the PV output and feedforward signals as the composite of the settings from the control loop, through such control of the temperature gradient to ensure the accuracy of temperature control system.

Circulation Pump

High temperature resistant low temperature magnetic drive pump or a leak-free high and low temperature shield-driven pump, reduce the risk of system leakage. At the same time the system has the advantages of low noise and big traffic flow.

Security

Many additional features to ensure the safe operation of the system. For the operation to run not normally appear in the alarm in time and displayed on the touch screen.

Phase sequence, leakage protection, refrigeration system high and low voltage protection, overload the pump, compressor overload, high and low level, two independent over-temperature protection, water protection, protection of the circulation line shut.

In comparison to other thermal control systems, Dynamic Temperature Control systems differ sometimes considerably in their thermodynamic characteristics. In practice Dynamic Temperature Control systems offer definite advantages in your work: noticeably shorther heating and cooling times, better stability and reproducibility through the entire process chain, greater safety for expensive glass reactors and the contained substances, together with simple and easy operation.

It is important to choose the suitable heat conduction medium, to make sure that system works stably. To choose the suitable medium according to the working temperature of the system is essential.

The package kinds of LNEYA heat conduction medium are 10L, 25L, 30L, 200L. when ordering the heat conduction medium, the heat conduction medium for constant temperature control system, channel, and external circulation equipments.

Technical Parameters:

Model |

SUNDI-225 |

SUNDI-235W SUNDI-235 |

SUNDI-255W SUNDI-255 |

SUNDI-270W SUNDI-270 |

SUNDI-2A10W SUNDI-2A10 |

SUNDI-2A15W SUNDI-2A15 |

|

Temperature range ℃ |

-25℃~200℃ |

||||||

Control Mode |

Feed forward PID + Our special dynamic control calculation, PLC controller |

||||||

Temp. control |

Option: process temperature control or jacket oil temperature control |

||||||

Temp. difference |

Set or control the temperature difference between jacket oil and raw material process |

||||||

Program Editor |

20 programs, each program can edit 45 steps. |

||||||

Communication protocol |

MODBUS RTU Protocol, RS 485 Interface |

||||||

Temperature feedback |

Heat-conducting medium: PT100 Raw material process: PT100 |

||||||

Temp. accuracy |

±1℃ |

±1℃ |

±1℃ |

±1℃ |

±1℃ |

±1℃ |

|

Heating power |

2.5kW |

3.5kW |

5.5kW |

7kW |

10kW |

15kW |

|

Cooling capacity |

200℃ |

2.5kW |

3.5kW |

5.5kW |

7kW |

10kW |

15kW |

100℃ |

2.5kW |

3.5kW |

5.5kW |

7kW |

10kW |

15kW |

|

20℃ |

2.5kW |

3.5kW |

5.5kW |

7kW |

10kW |

15kW |

|

-5℃ |

2kW |

3 kW |

4.5kW |

6.6kW |

8kW |

12kW |

|

-20℃ |

1kW |

1.8kW |

2.8kW |

3.8kW |

4.6kW |

7kW |

|

Circulation pump |

Max35L/min 2BAR |

Max35L/min 2BAR |

Max50L/min 2BAR |

Max50L/min 2BAR |

Max50L/min 2BAR |

Max110L/min 2.5BAR |

|

Compressor |

Copeland |

Copeland |

Copeland |

Copeland |

Copeland |

Copeland |

|

Expansion valve |

Danfoss |

Danfoss |

Danfoss |

Danfoss |

Danfoss |

Danfoss |

|

Oil separator |

LNEYA |

LNEYA |

LNEYA |

LNEYA |

LNEYA |

LNEYA |

|

Optional |

7-inch color touch screen controller, temperature curve record, data export to excel format. |

||||||

Self-diagnosis function; freezer overload protection; high pressure switch, overload relay, thermal protection device, liquid low level protection, high temperature protection and temperature fault protection. |

|||||||

Closed |

The whole system is full closed circulation, there is no oil mist at high temperature and no water vapor at low temperature, pressure do not rise up when system is running. The system will supplement oil automatically at low temperature. |

||||||

Refrigerant |

R-404A |

||||||

Connection size |

DN-20 or M24*1.5 |

DN20 or M30*1.5 |

DN20 or M30*1.5 |

DN20 or M30*1.5 |

DN20 or M30*1.5 |

DN-25 M38*1.5 |

|

Water-cooled type W (cooling water at 20℃) |

|

800L/H 1.5bar~4bar |

1000L/H 1.5bar~4bar |

1200L/H 1.5bar~4bar |

1600L/H 1.5bar~4bar |

2000L/H 1.5bar~4bar |

|

Dimension |

water-cooled |

|

500*680*1050 |

600*700*1150 |

600*700*1150 |

600*700*1150 |

600*700*1150 |

air-cooled |

400*600*1050 |

500*680*1350 |

550*680*1450 |

550*680*1650 |

620*680*1550 |

750*750*1750 |

|

Weight |

water-cooled |

|

135kg |

160kg |

205kg |

250kg |

280kg |

air-cooled |

115kg |

165kg |

285kg |

230kg |

280kg |

300kg |

|

Power |

AC 220V 50HZ 4kW (max) |

AC 380V 50HZ 6kW (max) |

AC 380V 50HZ 8kW (max) |

AC 380V 50HZ 11kW(max) |

AC 380V 50HZ 14kW (max) |

AC 380V 50HZ 21kW (max) |

|

Case material |

SUS 304 |

SUS 304 |

SUS 304 |

SUS 304 |

SUS 304 |

SUS304 |

|

Optional |

Optional Ethernet interface, configure PC operating software |

||||||

Optional |

Optional outside touch screen display controller (separated), the communication line distance is 10 meter. |

||||||

Optional power |

220V 60HZ three-phase, 440V~480V 60HZ three-phase |

||||||