Brand Name: OMS

Model Number: TBLU7mm(9.52mm)(12.7mm)-2+2+2/2700M4E6

Place of Origin: Guangdong, China (Mainland)

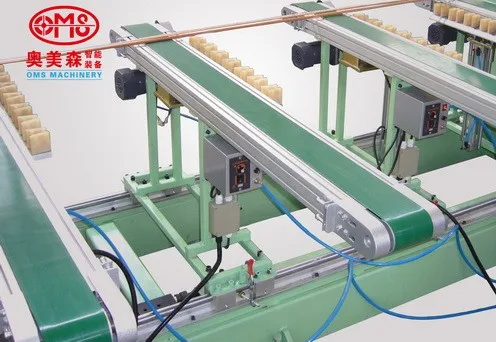

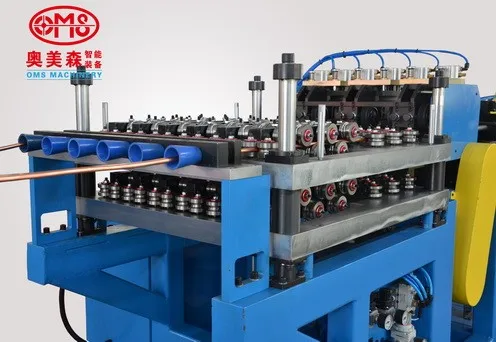

OMS hairpin bender consists of the following parts: decoiler, coil feeder and cut-off, bender and stripping section, collecting section, moving rails, hydraulic system, air system, and electrical control system.

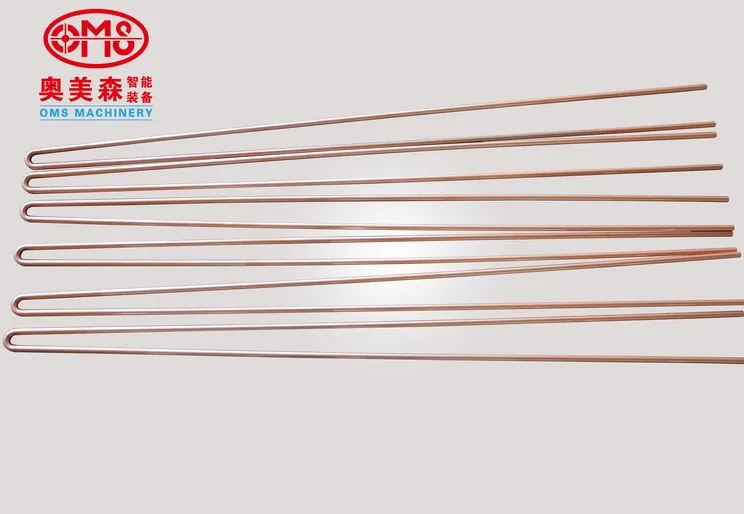

It uses servo motor to control bending, stripping and frame moving, which guarantees stable start-up, high speed and accuracy. The hairpin bend legs are straight and have the same length.

OMS hairpin bender can work for 24 hours a day with stable performance, low noise, and high accuracy. Its fault rate is very low, and is suitable for mass production.

The hydraulic system is reliable with no problems such as oil leaking or oil penetration.

The machine adopts transducer to soft-start the cutting motor, which prolongs the belt lifespan, achieving better cutting effect.

Good safety devices are equipped with OMS hairpin bender, such as light curtain, to guarantee operator safety.

The oil spray for mandrel is separately CNC controlled.

Item |

Specification |

|

Model |

TBLU7mm(9.52mm)(12.7mm)-2+2+2/2700M4E6 |

|

Material |

Processing material |

Coil copper tube |

Tube O.D & wall thickness(mm) |

Inner groove copper tube 7*0.30 9.52*0.32 12.7*0.38 |

|

Coiled tube weight |

Maximum weight: 180kg |

|

Processing capability |

Tubes bent at one time |

2 tubes |

Bending radius(mm) |

21mm |

|

Processing length |

Minimum 250mm Maximum 2700mm |

|

Efficiency (per cycle) (mm) |

L ≤300, t < 13s L ≤1000, t < 12s |

|

Processing quality |

Length accuracy |

±0.8mm/m |

Length difference between 2 legs |

≤ 0.5mm |

|

|

|

|

Flatness rate |

≤ 10% |

|

Height of burr |

≤0.2mm |

|

Pitch between two legs |

7 28mm; 9.52 25mm 12.7/ 41mm |

|

Surface quality |

No wrinkles, bumps, dents, orange peels, scratches, cracks. No burrs at tube ends. |

|

Cutting mode |

Exterior cutting |

|

Bending power |

Servo motor |

|

Bending power |

Servo motor |

|

Positioning power |

Servo motor |

|

Stripping power |

Servo motor |

|

Feeding power |

Frequency conversion motor |

|

Material decoiler |

6 motorized decoliers |

|

Power supply |

3 phrase 4 wire 380V \ 50Hz \ |

|

Air pressure |

0.4-0.6Mpa |

|

Operating environment |

0°C- 40°C, 60 - 95%RH |

|

Cooling method |

Air conditioner in electrical cabinet |

|

Total power |

Less than 15KW |

|