Brand Name: ARKREF

Model Number: --

Place of Origin: Shandong, China

CO2 Condensing compressor Refrigeration Unit with CE for cold room usage

CO2 Condensing compressor Refrigeration Unit with CE for cold room usage

Why choose CO2 transcritical refrigeration ?

With the implementation of refrigerant regulations like the Montreal Protocol(Global) and F-gas amendment (Europe), the quest for alternative solutions are accelerating. CO2 is now recognized as the most viable and efficient solution among natural refrigerants in food retail.

Today, CO2 refrigeration technology is matured and widely used. Everyday, manufacturers are focusing on the development of refrigeration components and configurations for sustainable and viable CO2 refrigeration systems.

Shandong Shenzhou has participated in the research and development of the CO2 system since 2014, after years of unremitting efforts and persistence, through industry practice accumulation and factory verification, to subvert the traditional design concept, leading the new field of carbon dioxide refrigeration technology.

Transcritical CO2 - Reduce complexity with one-global solution

Today, carbon dioxide refrigeration technology has proven to be a highly reliable and cost-effective solution in a wide range of climatic conditions. For more than a decade, the potential of carbon dioxide refrigeration technology has been recognized in cold climates. In recent years, forward-thinking vendors have promoted the application of new technologies, and new technologies are rapidly becoming energy-efficient solutions that help customers reduce complexity and meet current and future regulatory oversight of traditional refrigerants.

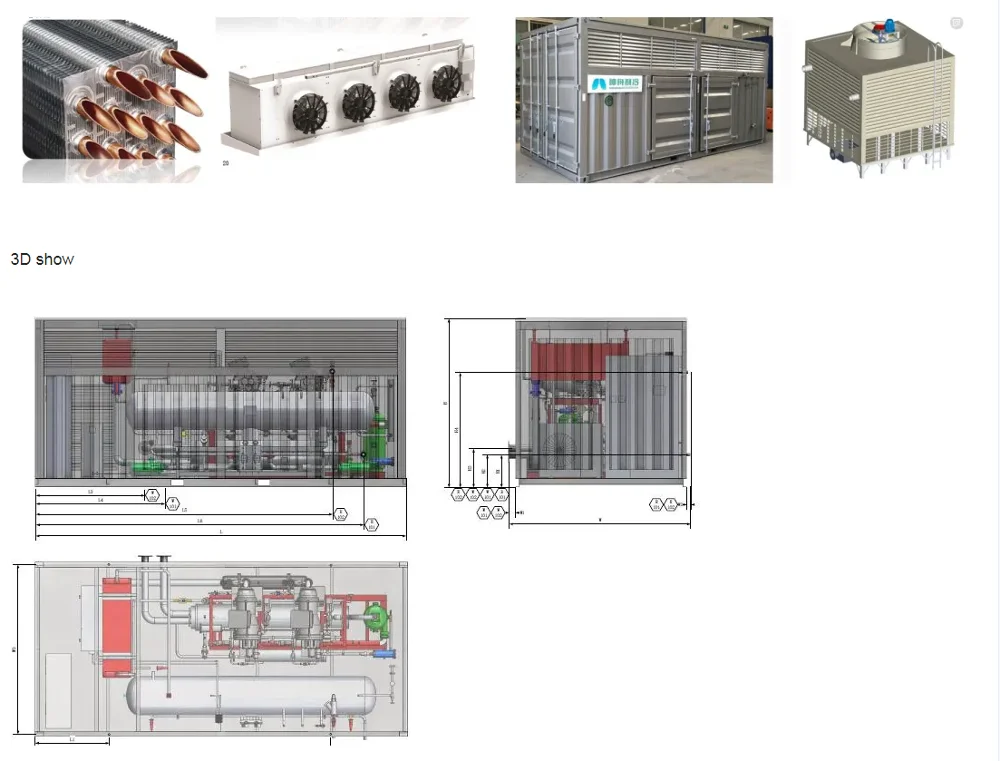

Shenzhou CO2 refrigerating station is the most efficient type of CO2 application in the market. It fully meets the stringent requirements for environmental protection and high efficiency. It is also easy to install and highly practical. The entire machine is designed in a skid manner, reducing the cold storage refrigeration system construction cycle by 95%. The re-evaluation of energy efficiency standards for refrigeration systems is a new definition of the safety, energy efficiency, environmental protection, and quality of refrigeration systems. It is an epoch-making innovation for cold chain equipment types.

Products show

Features

1.The complete unit adopts skid design, easily installed and maintenanced, the assembly period of the whole unit is less than 3 days.

2.The noise level could be lowered within 60 db,quite user-friendly ;

3.The new refrigerant R404A is more environmental friendly and has been accepted by the developed countries;

4.R744 works as the secondary refrigerant wihtout the compression, always working at the evaporation temperature so that the system could be working in a low pressure.

5.R744 flooded-liquid supply, which the efficiency is 30% higher than the conventional direct expansion system, and the COP is higher .

6.Factory assembly, factory commissioning, quality more stable.

7.Skid design, No specific plant room design needed.