Brand Name: Peritek

Model Number: ZHL-D-10000

Place of Origin: Hangzhou, Zhejiang, China

Low Dew point Desiccant Air Dehumidifier For Battery Baking, Electrolyte filling Room

Quick Detail:

Industrial Desiccant Air Dryers , Lithium Battery Ultra-low Humidity

1. Output temperature ≤16℃, dew point td≤-75℃

2. Be used for mixing workshop, coating workshop, production workshop, assembling workshop, etc,enable environmental index of these workshops to achieve 22±2℃, RH≤20%.

3. Consist of the fresh air filter, secondary silicone or molecular sieve rotor, fresh air surface cooler, return air surface cooler, fan, return air filter (tempering section and regeneration parts.

4. Regeneration heating by stainless steel tube electric heater or by copper tube aluminum fin steam heater.

5. Efficient centrifugal fans, high-strength structural framework, high-pressure foam double-sided enclosure, anti-cold bridge treatment.

6. PLC control, electric multi-protection, operation safety, stable and reliable.

Description:

ZHL Series lithium-ion battery industry dedicated dehumidifier mainly composed by condensing unit, direct evaporative heat exchanger or cold-water heat exchanger, super silica gel desiccant wheel or molecular sieve desiccant wheel, microcomputer control system.

According to battery work principle and process characteristics, production of battery have strict requirement for environment humidity, such as lithium-ion battery, lithium battery, lithium and thermal battery. So, ultra-low humidity dehumidifier is indispensable in production of battery, its dehumidifying performance impact battery electrical property and safety directly. This lithium-ion industry dedicated dehumidifier has been proved qualified in lithium-ion battery industry.

Output temperature ≤16℃, dew point td≤-60℃.Be used for liquid injection room, baking room and formation room with special require etc,enable these workshops to achieve 22±2℃, RH≤1%,also can adjust air temperature and humidity according to the actual requirements.

Character:

Model Example:

ZHL-D-2000

ZHL: Ultra-low low humidity dehumidifier units basic code

D: Rotary regeneration type. D for Electricity, Z for Steam.

2000: Process airflow m3/h

Main Parameters of ZHL Series Ultra-low Humidity Dehumidifier:

|

Main Parameters / Model |

ZHL-2000 |

ZHL-3000 |

ZHL-5000 |

ZHL-15000 |

|

|

Process Air |

Airflow m³/h |

2000 |

3000 |

5000 |

15000 |

|

Fan Power kW |

2.2 |

3.0 |

5.5 |

15.0 |

|

|

Regeneration Air |

Airflow m³/h |

500 |

750 |

1250 |

3750 |

|

Fan Power kW |

0.75 |

1.1 |

1.5 |

3.0 |

|

|

Regeneration Mode |

Electrical Heating Power kW |

15.6 |

24.0 |

39.6 |

120.0 |

|

Steam Consumption kg/h |

27 |

40 |

66 |

200 |

|

|

Drive Motor Power kW |

0.13 |

0.16 |

0.18 |

0.37 |

|

|

Attemperation Electrical Heating Power kW |

3.6 |

6.0 |

9.0 |

24.0 |

|

|

Outlet Air |

Temperature °C |

20-25 |

|||

|

Relative Humidity % |

≤-60 |

||||

|

Supporting System Refrigerating Capacity kW |

31.5 |

47.5 |

78.8 |

236.0 |

|

|

Installed Power |

Electrical Heating kW |

22.28 |

34.26 |

55.78 |

162.37 |

|

Steam Heating kW |

6.68 |

10.26 |

16.18 |

42.37 |

|

|

Overall Dimensions |

Length mm |

4500 |

5000 |

5400 |

6800 |

|

Width mm |

1180 |

1330 |

1630 |

2380 |

|

|

Height mm |

1930 |

2180 |

2750 |

3450 |

|

|

Weight kg |

1700 |

2000 |

2700 |

5000 |

|

Note:

Competitive Advantage:

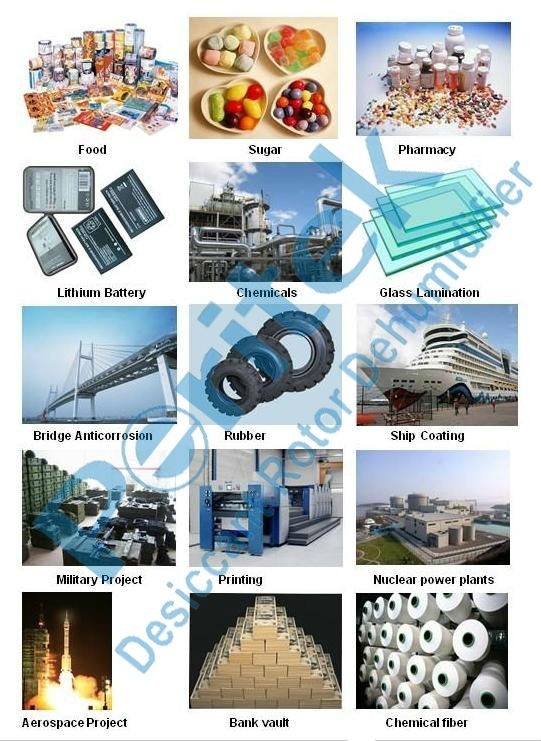

Typical Application Fields:

1. Warehouse, Library and Archives:

2. Pharmaceutical Industry:

3. Electronics Industry, Lithium Battery

4. Chemical Fiber Industry:

5. Food Processing Industry:

6. Space and Aviation:

7. Glass Lamination

8. Ship Coating

9. Bridge Anticorrosion

10. Rubber Tire

11. Nuclear power plants

12. Printing

Work Principle:

Device is a combined type, which has functions of air filtering, cooling dehumidification, rotor dehumidification, air supply and temperature adjustment, etc.When fresh air go through the filter ,enter into and contact fully with the surface cooler, due to the surface

temperature below the air dew point temperature, air cooled,at the same time, the included water turning into condensed water separated out, then the air temperature and humidity decrease, the low temperature and humidity air mixing return air of the drying room, after tempering by return air surface cooler ,enter into the desiccant rotor for further dehumidification. At last, after tempering, we get the dry air, which is sent to dry room to meet the technological requirements