Start Order

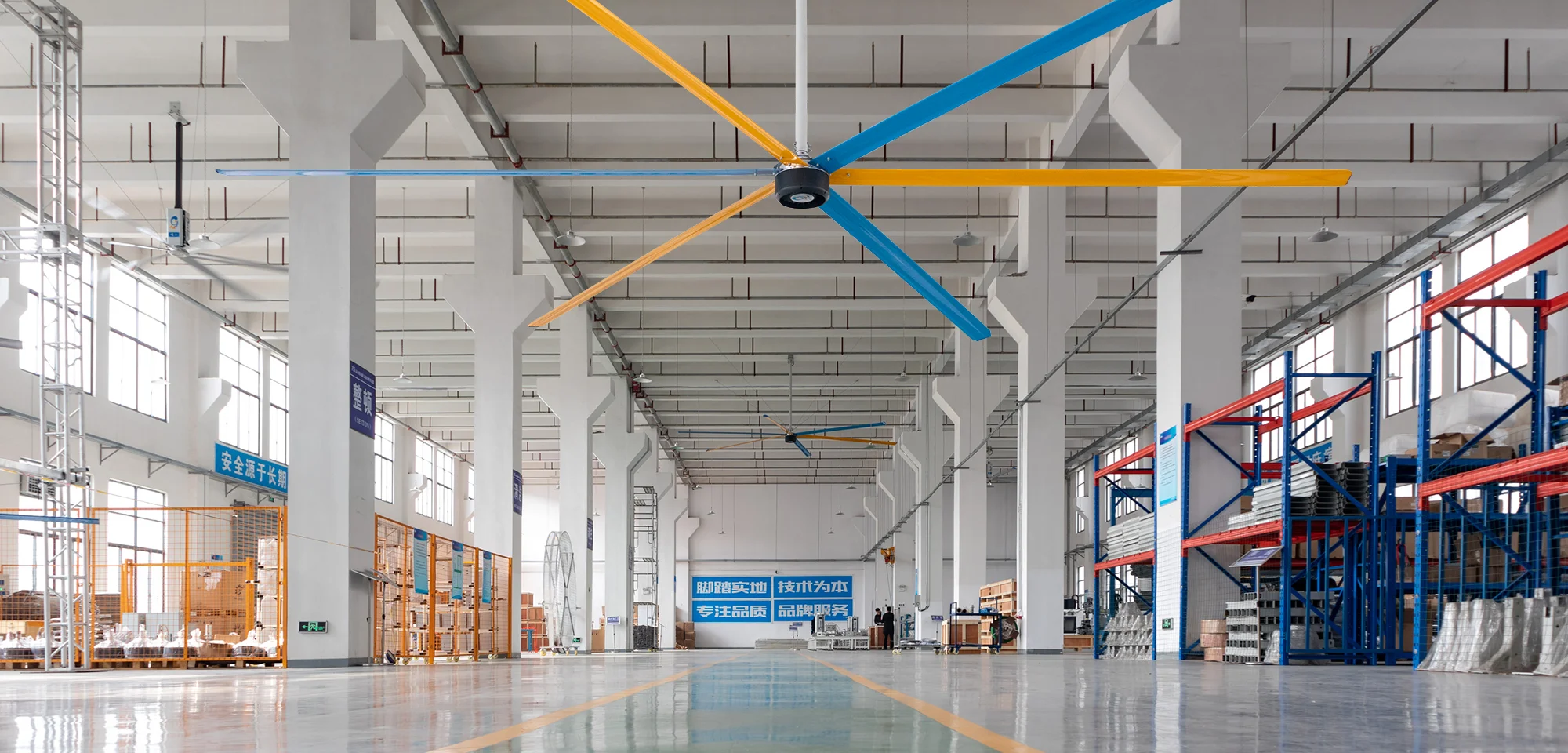

Jiangsu Gaxiao Technical team researched and developed domestic first industrial fan from the 2008 to the market, so far has gone through 11 years, we have always adhered to the "down to earth, technology-oriented, focus on quality, brand name service" concept, won the full trust and love of domestic and foreign customers.And in 2018, combine with the global concept of "energy saving, low carbon and environmental protection" at first, we achieved the second technological revolution in the field of ventilation and cooling of industrial fans.With the rapid development of science and technology, high and new technology is constantly emerging, energy saving and environmental awareness are increasing. In the field of power system, China attaches great importance to the research and development of NdFeB permanent magnet motor, and has been included in the national "863" plan.Jiangsu Gaxiao allied with Tsinghua University Polytechnic Institute and Zhejiang University Polytechnic Institute, the PMSM permanent magnet synchronous motor technology is first applied to the HVLS large industrial fan field under the guidance of the national strategic policy. The first permanent magnet synchronous motor technology in the world is developed and manufactured, and the "battle axe" series is born in the times. In the process of the second technological revolution of industrial fans, they added another chapter.At the same time, Gaxiao commercial fan series products after continuously testing, have abandoned traditional spur gear transmission technology, and selected the spiral gear transmission technology with better meshing performance and greater coincidence degree. The meshing process between the helical gear teeth is an excessive process, and the force on the tooth is gradually from small to large, then from large to small.With the increase of the coincidence degree, the bearing capacity of the gear is improved, thus prolonging the life of the gear. Motor gears are just as important as human joints this breakthrough has greatly improved the service life of commercial products under the same environmental factors. We strive to bring the best quality products to consumers and bring the most comfortable experience to users. In the field of practical, security, energy conservation and environmental protection to achieve the world's leading level, in fact have become a terminator of complex space environment ventilation cooling problem.Jiangsu Gaxiao Environmental Technology Co., ltd has newly introduced driving motor of the permanent magnet industrial fan, which is developed by Jiangsu Gaxiao, Tsinghua University and Zhejiang University. This product is a new type of fan based on PMSM, permanent magnetic synchronous motor technology.The main engine reducer adopts high precision helical gear transmission, with smooth transmission, less impact,vibration and noise;Compared with oridinary spur gears, helical gears have the following advantages:1.The meshing performance is good: the meshing process between the helical gear teeth is an excessive process, and the force on the tooth is gradually from small to large, then from large to small; the helical gear is suitable for high speed and heavy load conditions.2 The coincidence degree is large: the increase of the coincidence degree increases the bearing capacity of the gear. Thus the life of the gear is prolonged. The coincidence degree mainly depends on the engagement time, while the helical gear has a long engagement time and a large contact area, and reduces the stress. It also makes the transmission smooth, and increases its economy.3 Compact structure: the smaller the minimum number of teeth, the more compact the structure.Traditional 'seventh generation' Industrial large fan Import American Airlines AA7075 super hard alloy + Japanese precision high pressure forging technology (sigma B 600Mpa) +T6 heat treatment +CNC precision machining + dynamic balance check quality:

Hub

Hub Motor

Motor

Controller system

Controller system

Fan blade

Fan blade