Product Description

The Coaxial heat exchanger consist of one spiral grooves inner tube and a outer tube. Cold liquid and heat liquid flow in the gap that between inner and outer tube or in inner tube separately.

Structure Feature-1

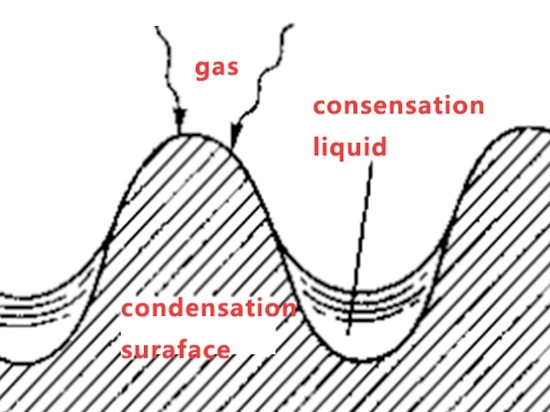

After refrigerant is condensed, liquid film on the rib structure of inner spiral grooves tube will become thinner by surface tension, so it will reduce heat transfer resistance.

Structure Feature-2

Spiral grooves structure can enhance the heat transfer at both sides. Liquid will flow at axial direction and rotate in radial direction and create locally secondary flow, thus increase the mixture between liquid near the wall and that in the center of the flow pass.

Inner tube material

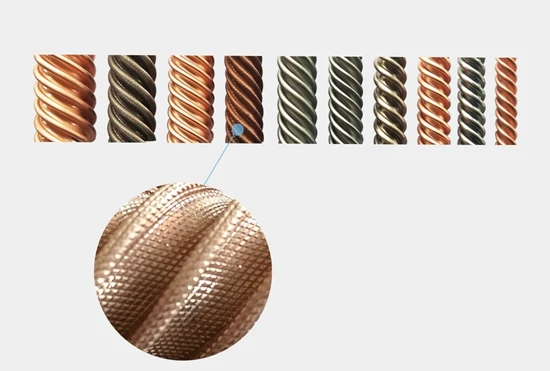

Inner tube material can be: red copper, cupronickel(BFe-10-1-1), Titanium, Stainless steel. And inner tube can be choosed by smooth tube or enhanced surface tube. And there are also double-wall copper inner tube.

Outer tube material

Depending different working condition, outer tube material can be: steel, red copper, cupro-nickel, titanium, stainless steel etc.

Single system Structure & Shape

Multi system shape & structure

Coaxial heat exchanger- features

1-Anti freezing

Water is not easy to get frozen because water is in a turbulence state as flow in the spiral groove inner tube at low speed. And the special spiral groove sturcture of inner tube makes the inner tube has a ability of flexibility, so it will not risk of frost crack.

2-Self cleaning, no block

Fluid flow helically to scour the surface, so the coaxial heat exchanger has a bility of self cleaning. And the coaxial heat excahnger's performance is stable and has less attenuation. The sectional area of water passway is bigger so it allowed silt, fiber of big diameter to get through without get blocked. The passeay of water is clean because spiral grooves inner tube makes water flow in turbulence state that will clean the surface.

3-Less welding points, higher pressure stand, more reliable

Because sipiral coaxial heat exchanger has few welding points with easy processing, the welding quality is easy to control. And it has little risk of leakage that may cause by prolonged vibration, pressure fluctuation, cold and heat alternation.

4-High efficiency

Spiral grooved structure can have the effect of strengthening heat transfer on both sides. Both the axial flow of fluid in the tube and the screw rotating flow will exacerbated fluid mixing near the wall, which will enhance the turbulence intensity, increased heat transfer coefficient.

5-Enhanced heat exchanging

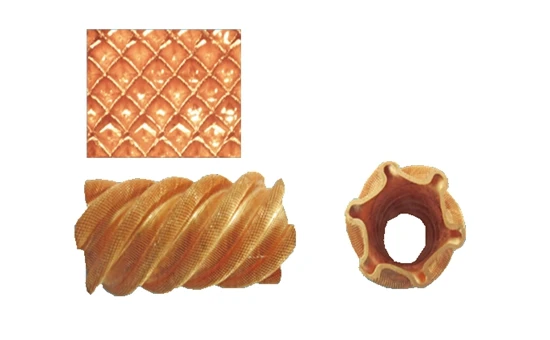

(1) There are net dentation that will enlarge the contact area of fluid and inner tube surface.

(2) Net dentation can highten the turbulence and increase the Reynolds Number, so it will decline the thick of boundary layer of fluid.

As a consuquence, heat transfer coefficient is higher, heat transfer amount in 1 unit volume is more and heat transfer performance is much better.

6-Long serve life

When the refrigeration system in practice, due to temperature fluctuation, start-stop cycle, heat pump defrost, expansion valve regulation and other factors, internal pressure is frequently alternating condition. Under the constant vibration and pressure changes, the spiral coaxial heat exchanger is much more capable of resisting pressure shock and pressure shock than the plate heat exchanger, so it can adapt to the complexity of the actual working conditions.