Silicone Keys Vulcanization / Curing Vulcanizing Autoclave / Vulcanizer Made in China

1. Product Description

General structure: The working pressure of horizontal autoclave is generally less than 1.2MPa, belonging to low pressure vessel. Single cylinder structure is composed of a tank, tank cover and a switch locking device, heating device and other auxiliary equipment. The tank door structure is quick open with tooth type.

2. Applicable Scope

A. Vulcanization Mechanical Property Enhancement Equipment New tire Solidification, Tire retreading, Rubber hose, Rubber Pulley, Cable, Pipeline

B. Vulcanization and Reclaimed Rubber Desulfurization: Rubber Capsule, Rubber Sheet, Rubber Gloves, Rubber Shoes, Rubber belt, Rubber Cloth, Rubber Head

C. High Temperature & High Pressure Vessel: Degreasing, Hydrolysis, Impregnation Treatment, Setting, Oxidation Treatment, Steaming, Cooking, Drying

a. High temperature & high pressure processing: Styrene butadiene rubber thermoplastic; bamboo carbonization and Degreasing

b. Large fire prevention, mothproof, anti-corrosion, anti tank deformation pressure impregnation.

c. Railway sleeper treatment, wood sterilization, wood carbonization, wood optimization, wood impregnation, wood fire retardant, wood dyeing, wood cooking, wood preservation

d. High temperature & high pressure treatment of yarn thread, mane, socks heating setting

e. High temperature and high pressure steam modification treatment of horn and bone, degreasing, all kinds of feather hydrolysis

f. Steaming, cooking, impregnation, drying carbon material, asbestos friction material

3. Features

1. Sealing method of door: adopt inflatable seals.

2. Heating fast & constant temperature, air is circulated by fan.

3. Wind board avoids products touch heat exchanger directly.

4. Indirect heating with cyclone fan for even temperatures.

5. Multiple safety interlocks ensure safety during process.

6. Rock wool filled in insulation layer to keep heat saving.

7. High temperature accuracy, pressure controlled automatically.

8. Meet ASME or International Standard.

4. Technical Parameters

The design temperature and design pressure of the curing autoclave is 190℃ and 0.85MPa.The common specifications are here,you can also customize your wanted size according to your specific requirements.And the thickness is generally 8,10,12 mm.

Design Temperature(℃) |

190℃ |

Design Pressure(MPa) |

0.85MPa |

Trial Pressure(MPa) |

1.0MPa |

Total Capicity(m3) |

50 m3 |

Material |

Q345R |

Specifications |

Common specifications: Diameter * Effective Length 800*3500mm 1000*2000mm 1500*4000mm 1800*6000mm 2200*10000mm 3000*4000mm Can be customized according to customer requirements |

Heating Type |

Electric heating |

Class |

Class One |

Medium |

Air |

Medium Characteristics |

Non flammable, non-toxic |

Material of main Pressure Components |

16MnR,16MnⅡ |

Corrosion Allowance (mm) |

1.0 |

Welded Joint Coefficient ( φ) |

0.85 |

Safety Valve Pressure ( MPa) |

1.35 |

Thickness ( mm) |

8/10/12 |

5.Product Pictures

a. Electric Heating Curing Autoclave

b. Indoor Setting

c. Components

d. Without insulation Vulcanization

e. Fault Detection

Detection of cracks or defects in metallic materials or components X-ray inspection

f. Water Pressure Test

6. Packing &Delivering

We will deliver your goods by LCL/20'FCL/40'FCL depending on your order.

Before delivery, our professional technician will do trial run for each product to make sure no problem, you can come to our factory and test our machine together with us.

When loading, our workers will fix the retorts tightly with steel wire rope so that the retorts can't move arbitrarily in the container.

7. After-sale Service:

>One year free warranty

>Technician-online support

> E-mail, CD/ DV or software to solve detailed questions.

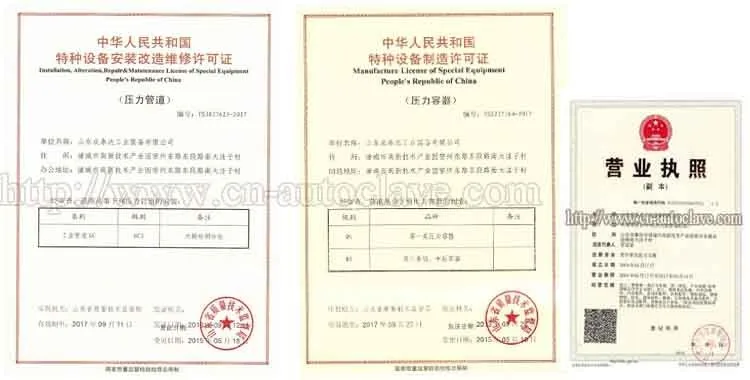

8. Company Certificates

9. Company Introduction