Steam Heating Wood Preservative Autoclave For Masson Pine

1. What is pressure treated wood?

Pressure treated wood is wood that has been treated with a preservative to protect it from being destroyed by insects, fungus or exposure to moisture.

Wood Processing: Wood drying, wood preservative, wood fire prevention, wood impregnation, wood modification, wood optimization, wood fire retardant, wood color, wood cooking, bamboo carbonization and so on.

2. Applicable Scope

Those treated wood are commonly used for decks, walkways, fences, gazebos, outdoor furniture and flooring, courtyard, yacht marina, park chair, flower bed, grape trellis, wallboard,boat docks and playground equipment.

3.Working Principle

It combines vacuum and pressurizing.

A: Vacuum: suck out air out of tank and wood cells, which makes it easy for chemical agent to be absorbed into wood cell.

B: Pressurizing: help chemical agent go into wood cell with pressure.

4. Working Orders:

In the normal temperature, put the clean and dry wood into the processing tank.

Firstly, Vacuum: suck air out of the tank and wood with vacuum pump and keep the vacuum status for 15minutes to 1 hour according to treatment aims. Vacuum status is good for liquid going into the wood. Thevacuum degree can be 0.098MPa.

Secondly, Adding Liquid: under condition of vacuum, put liquid into tank.

Thirdly, Pressurizing: when the tank is full of liquid, pressurize with pressure pump. The pressure inside tank will rise slowly to rated pressure. Then keep the tank under rated pressure until wood have absorbed enough liquid.

Fourth, Pressure Relief: when wood have absorbed enough liquid, relief the pressure inside the tank.

Lastly, Vacuum: when the rest liquid has been discharged, suck air out of tank and wood with vacuum pump again to make redundant agent liquid exude from wood cells or surface to avoid liquid from dropping.

5. Features

1) Wood treatment equipment apply to be preservation, termite proof and to prevent fungal. Especially outdoor wood floor, landscape floor, outdoor wood platform and wood plank road and other preservative wood pergola.

2) This treatment equipment has special process for wood, such as: vacuum pressure method, full cell method, low frequency high pressure as so on. Especially vacuum pressure method. The preservative level can get C4.

3) You can use CCA and ACQ two kinds of preservative to match our wood preservation equipment.

4) PLC is a new intelligent control wood preservative system, which make the wood preservation equipment to be easy, safety and reliable. Meanwhile, Even if the wood isn’t be push out, this can be calculated accurately if the preservative is permeated in the wood.

6. Technical Parameters

The design temperature and design pressure of the wood autoclave is 200℃ and -0.08-3.6MPa.The vaccum degree is 0.098MPa.The common specifications are here.

| WOOD AUTOCLAVE / PROCESSING EQUIPMENT | |||||

| Diameter | Length | Capacity | Working Pressure | Working Temperature | Vacuum Degree |

| 1-2.4meters | 4-24meters | 2-20M3/ tank | -0.08-3.6MPa | 0--200℃ | 0.098MPa |

The temperature, pressure and curing time of the wood autoclave is controlled automatically. The diameter is 1000-2400mm and length is 4000-24000mm. It can be designed and customized to meet the customer's different technical requirements.

7.Product Pictures

8. Prepairation Working Before the Forming

A. Insulation Process of the Autoclave

Firstly, drilling holes used in the following steps in the tank in advance.

Secondly, put steel rings welded on the tank. The rings are used to fix the mineral wool.

Thirdly, use glass mineral wool to wrap around the tank body for preservation.

Lastly, use insulation board to be welded around the tank.

It is finished.

B. Fault Detection

Purpose: Detection of cracks or defects in metallic materials or components X-ray inspection

C. Water Pressure Test

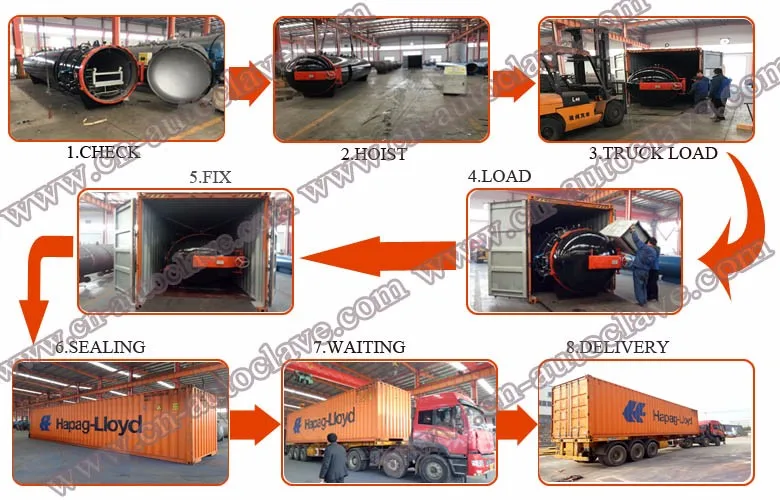

9. Packing & Delivering

We will deliver your goods by LCL/20'FCL/40'FCL depending on your order.

Before delivery, our professional technician will do trial run for each product to make sure no problem, you can come to our factory and test our machine together with us.

When loading, our workers will fix the retorts tightly with steel wire rope so that the retorts can't move arbitrarily in the container.

10. After-sale Service:

>One year free warranty

>Technician-online support

> E-mail, CD/ DV or software to solve detailed questions.

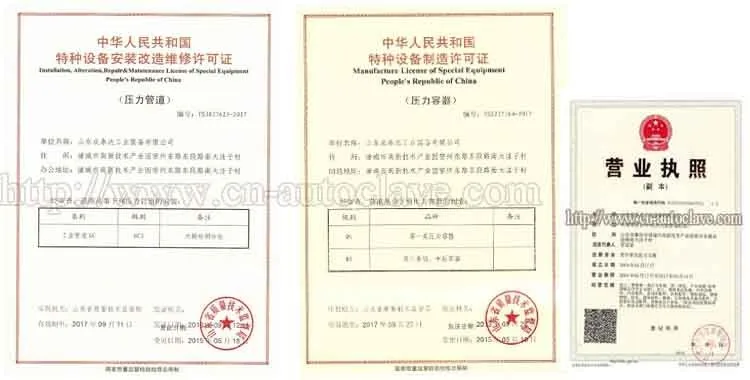

11. Company Certificates

12. Company Introduction

Shandong Zhongtaida Industrial Equipment Co. Ltd. is one of the largest and most professional manufacturers of pressure vessel vulcanizing equipment in China. Our company has complete qualifications, advanced equipment, strong technical force and complete testing means with stable quality assurance system. Main products: all kinds of small, medium and large full automatic, semi automatic, electric heating vulcanization, steam vulcanization, electric steam vulcanization , giant vulcanization, vertical vulcanization, indirect heating vulcanization, rubber vulcanization, tire retreading vulcanizing, rubber covered roller vulcanization, rubber hose vulcanization, rubber capsule vulcanization, rubber shoes vulcanization, belt vulcanization, conveyor belt vulcanization , pipeline vulcanization, cable vulcanizing tank, desulfurization equipment, steam equipment and other equipment. Our company is a modern new enterprise which integrates design, manufacture and installation in one whole.

Our Workshop

Company Front Door

13.Our Clients

They are visiting our products in the workshop. Our engineers are introducing the functions and characters of the products. If you are interested in our products, welcome to here and you can receive many unexpected harvest!

14.Contacting Information

Waiting for your inquiry!

Best wishes to you.