1. Product Description:

The pot is mainly composed of the horizontal body, the heat exchanger, the circulating water pump, the pipeline and various valves, as well as the automatic control system. It is divided into top pouring type, side spray type and full spray type. In this way, the hot water is sprayed out of the spray nozzle and pipe to the surface of the food. No dead angle.

2. Applicable Scope:

Mainly applicable to canned food (such as meat, fish, eggs, vegetables etc.), protein beverage (milk, soy milk, coconut milk, peanut milk, walnut milk, almond milk etc.), hard cans (tin cans, glass bottles, cans etc.) and various kinds of soft packaged food.

Metal Containers: tin cans

Aluminum Cans Plastic Containers: PP bottles, HDPE bottles

Soft Bag Packaging: aluminum foil bag, transparent bag, vacuum bag, cooking bag and so on

3. Working Principle & Features

Working Principle:

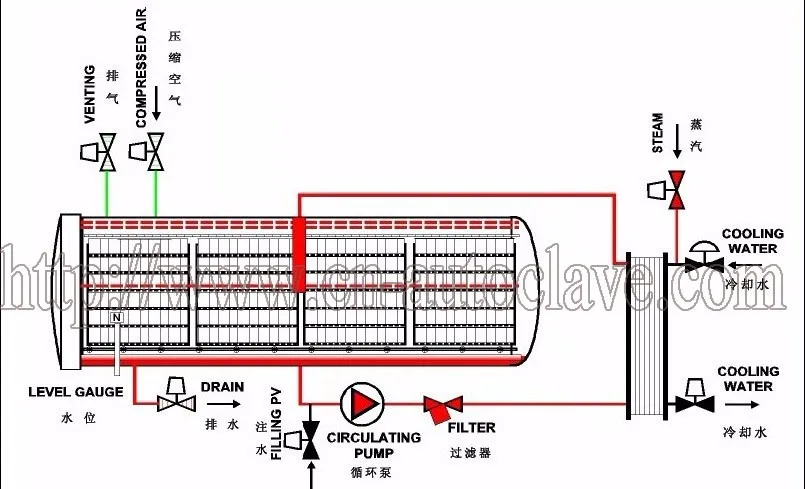

Principle Diagram

1. Uniform temperature distribution:In the process of heating and sterilization, the water is continuously sprayed from nozzles adopted high speed spraying, so that the temperature in the pot is kept stable and the sterilization effect is improved.

2. Direct heating and indirect cooling, and prevent the second pollution. Sterilizing and cooling processes use the same water. Circulating water is directly heated by steam diffusion tube in the heating process. Under 0.5MPapressure, it only takes 6-12min to rise the temperature from 20 DEG to 121 DEG. Continuous cooling by heating exchanger is isolated from the products, preventing the second pollution in the cooling effectively.

3. Full-automatic control system:

b. No-paper recorder

c. Imported Automatic Valves

d. Many sterilization techniques in memory for your choice. At most could save 250sterilization formula.

4. Pressure control system independently, suitable for gas packaging sterilization: Pressure(±0.005Mpa)

Pressure control system can correct and balance the pressure inside of the pot and packing automatically, not damaging the packing or the contents.

5. Heating and cooling in stages can reduce the temperature difference between the surface and the center of the food in protection of fragile food and glass bottles.

4. Technical Parameters

This model is PLJ14-3.B.3, inner diameter is 1400mm, vessel length is 3000mm.The total length, width and height is 3938mm, 1600mm, 1880mm. The working capcity is 4.6 cubic metres. The thickness of the autoclave is 5m with 0.3Mpa and 147℃.

Water Spray Autoclave/Retort/Sterilization Pot |

|||||||||

Model No. |

Outside Measurement(mm) |

Inner Diameter(mm) |

Vessel Length(mm) |

Capacity(m³) |

Thickness of Autoclave(m) |

Max Working PRE.(Mpa) |

Max Working TEP.(℃) |

||

Length |

Width |

Height |

|||||||

PLJ.14 -3.B.3 |

3938 |

1600 |

1880 |

1400 |

3000 |

4.60 |

5 |

0.3 |

147 |

5. FAQ:

Q: Are you manufacturer or trading company?

A: We are a professional manufacturer.

Q: Where is your factory located?

A: Our factory is located in Zhucheng, Shandong, China. From Qingdao where closes to us 1.5 hours to Beijing, 1.75 hours to Shanghai, 4.5 hours to Guangzhou by air.

Q: What is your business scope?

A: There are three categories, such as kettle, rubber vulcanization and food sterilization pot.

Q: How could we confirm the details of the products?

A: We will provide all the drawings for you to confirm or you can come here to conduct investigation.

Q: Will you charge us for drafting if we have special requests?

A: No, we will not. Free of charge to make a draft or offer.

Q: How long the warranty will be?

A: 1 Year warranty.

Q: How about the installation? And what if the machine goes down?

A: We will do that. There are two options.

a. We could appoint our engineer to your company to debug and repair, as for the cost of this trip such as ticket, visa, accommodation and labor cost shall be on your side.

b. On-line service will be provided. If still is under guarantee period, the necessary accessories and parts will be provided free, but the transportation cost of it shall be on your side.

Q: Do you take L/C?

A: Yes, we accept L/C, T/T and irrevocable L/C payable.

Q: Can we become your distributor in our country?

A: Yes, welcome you! More details will be discussed if you are interested in being our agent.

6. Product Pictures

a.Cross Spraying Type Autoclave

b. Showering Type Autoclave

c. Used equipment and facilities

Reeling Machine

d. Water Pressure Test

Pressure to test the water, check there is leak or not in the tank.

If there is serious water leakage, stop the water pressure test and repair it.

e. Insulation process of the autoclave

Firstly, drilling holes used in the following steps in the tank in advance.

Secondly, put steel rings welded on the tank. The rings are used to fix the mineral wool.

Thirdly, use mineral wool, the material of which is aluminium silicate, to wrap around the tank body for preservation.

Lastly, use insulation board to be welded around the tank. It is finished.

7. Packaging &Shipping

Before delivery, our professional technician will do trial run for each product to make sure no problem, you can come to our factory and test our machine together with us.

When loading, our workers will fix the retorts tightly with steel wire rope so that the retorts can't move arbitrarily in the container.

8. Here is our Business License and Manufacture License of Special Equipment