Brand Name: ECM/OEM SERVICE, ECM

Model Number: --

Place of Origin: Zhejiang, China (Mainland)

Lin'an E-COOL Refrigeration Equipment Co., Ltd. (E-COOL Manufacturing Co., Limited) is specialized in the production of R11, R12, R134A, R141B, R412B, R290A, R401A, R402B, R404A, R406A, R407C, R410A, R415B, R417C, R502, R507, R600A, etc. Besides we have welding tools for refrigeration. MAPP gas & propane MAPP pro are our superior products in China. We have accumulated much experience in business and have developed into one of the most prominent and largest suppliers and producers of compressors, motors, components, refrigerants and A/C spare parts in China.

1.Production Description

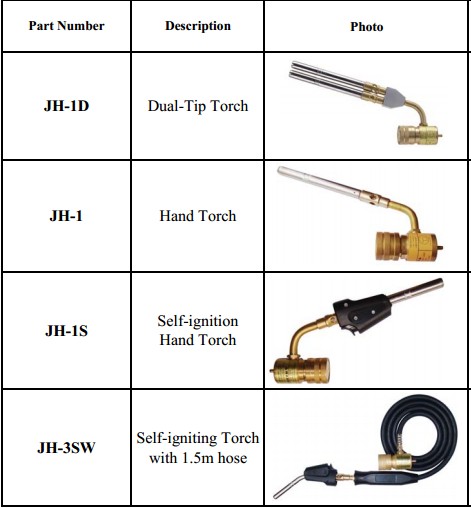

weld torch,dual tip torch JH-1 JH-1S JH-3W JH-3SW JH-1D1

Typical applications |

|

Qxygen is not needed |

Used for copper/brass fittings welding/brazing |

| CGA600 connection | HVAC after market |

| High working temperature | |

| Dual-tip torch(both the bent tube and the tip can swivel 360°) | |

| Easy ignition with self-ignitor | |

| Adjustable pressure | |

| Used with MAPP or Propane tanks |

|

Other hot related products

Mapp gas

Mapp gas physical and chemical property:

1. .Its diameter is 75mm, height 267 mm and gross weight 980g, convenient for holding and carrying.

2. . The welding temperature can be reached 1250°C and the burning temperature can be reached 1980°C under condition of anaerobic combustion-supporting.

3. . The burning time can be gottten 2hours and 40mins continuance under normal working circumstance.

4. . It guarantees you good jointing and shorter working time because of its scientific blend proportion and favorable flame characteristic.

5. MAPP GAS packing specs: 16oz/453.6gm per cylinder, 12 cyls per ctn, 17004 cyls per 20ft container.

Propane gas

Product Name : Propane gas

Product Category: Welding & Brazing gas

propane is a three-carbon alkane, normally a gas, but compressible to a liquid that is transportable. It is derived from other petroleum products during oil.

Propane produces a lower flame temperature than acetylene (the maximum flame temperature in oxygen is 2,828C compared with 3,160C for acetylene). Consequently, piercing is much slower but as the burning and slag formation are effected by the oxygen jet, cutting speeds are about the same as for acetylene.