Brand Name: JinPin

Model Number: Depends on Tube's model,diameter and material

Place of Origin: Shandong, China (Mainland)

Square pipe roller/mould/die/maker for ERW machine

Product Description

Mould style |

Breakdown/forming rolls

Fin pass rolls

Welding rolls

Sizing rolls

Turk’s head rolls |

Mould material |

Cr12,Cr12Mo1V1,Cr12MoV SKD11 D2 D3 Any special material according to your requirement |

Produced Pipe Shape and size |

round steel pipe:Φ8(mm)-Φ711(mm)

square steel pipe: can be as large as 550*550(mm)

cold roll forming pipe: U-shape W-shape Z-shape steel sheet pile, color coil, section bar and so on

any special shape can be customer-made |

Strong hot sell point |

1. advanced groove design

2. strict analysis and inspection of raw materials

3. special heat treatment technology

4. precision machining

5. advanced quality control system |

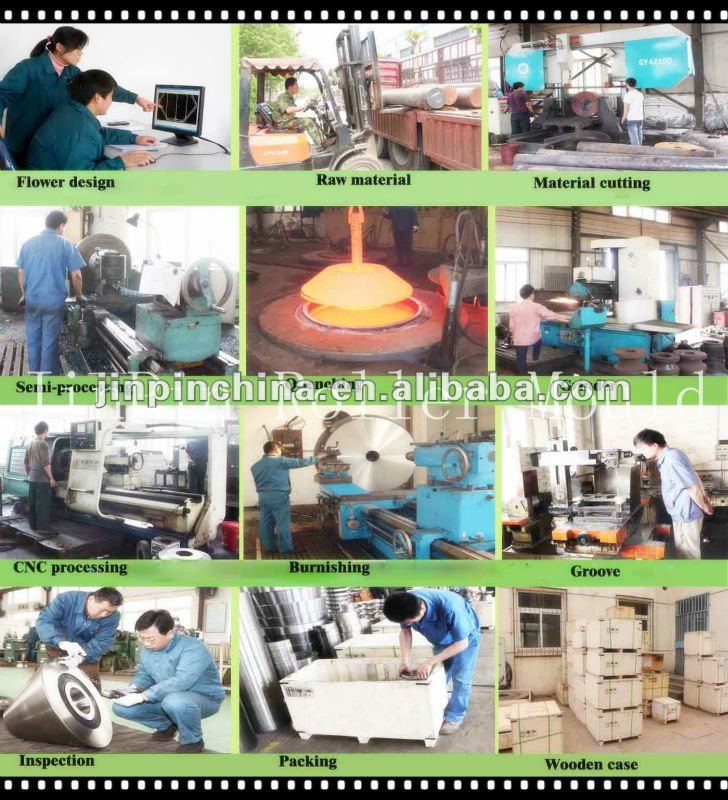

Mold processing line

Packaging & Shipping

1.Inner package: water-proof and shock-proof plastic and choth.

Outer package:firming wooden cases

2.Special requirement according to your request

Produced Pipe Shape and size

1. round pipe: Φ8-Φ273(mm)

2. square pipe: min 10*10(mm)

max 215*215(mm)

3. allotype pipe: U-shape, P-shape, Z-shape, and so on

Satistics of forming results

Payment Terms

1. Paypal or Aliexpress for small amount.

2. for mass order: By T/T, 30% deposit after order confirmed, balance to paid before shippment.

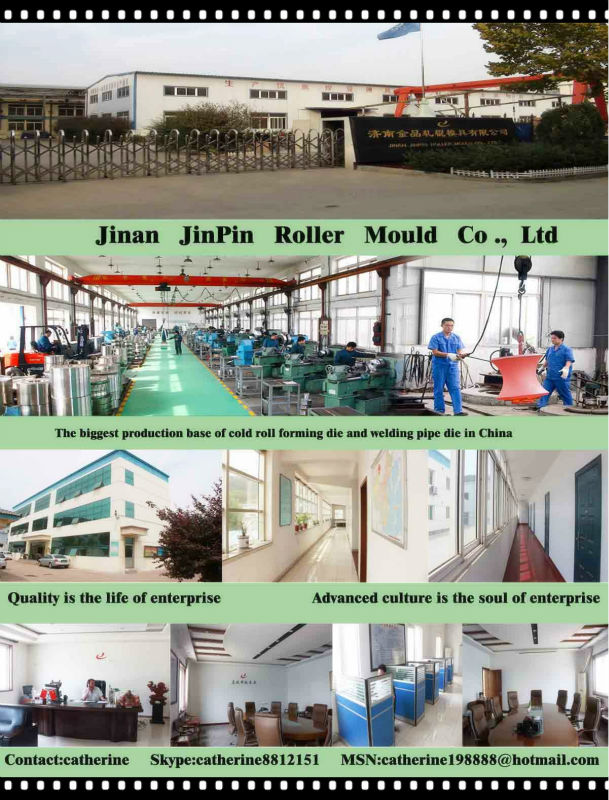

Our company

Established in 1994, Jinan Jinpin is a composite company which can design and manufacture high frequency tube welding equipments, rollers, ferrite rods and cold roll forming equipments. Its main products are various types of high frequency tube welding equipments, cold forming steel units, ferrite rods, welded pipes, cold bending moulds and magnetic rollers for hot galvanizing line etc.

The company has three branches with a total staff about 200 people. It has strong technical strength and processing capacity. The high chromium alloy, which is the wear-resistant materials, developed by the company independently obtained national patent, and has been successfully applied to its rollers manufacture. The rollers’ service life is 1.5 times of the common ones. The high frequency tube welding equipments, researched and developed by itself , have automatic adjustment function, need not to replace the rollers in the rough forming section. Time , effort and cost saving achieved.