Brand Name: CF

Model Number: HI-NBR

Place of Origin: Guangdong, China (Mainland)

HVAC NBR/PVC Thermal Insulation Foam Description

CF NBR Insulation Foam Tube

CF NBR is a uniquely formed closed cell flexible elastomeric insulation, used to insulate heating, ventilating, air-conditioning, refrigerating (HVAC/R). High quality CF NBR insulation tube and sheet provides thermal efficiency that reduces undesirable heat gain in chilled water systems, cold water plumbing, and refrigeration lines, air conditioning lines, cooling ductwork and equipments. When properly installed, this product also provides condensation and frost control on cold surface. CF NBR insulation material also efficiently reduces heat loss for hot water plumbing, liquid heating and dual temperature piping. CF NBR Self-Seal Tube / Sheet Insulation is also CFC/HCFC free, non-porous, fiber free, dust free and resistant to mold growth. The recommended temperature range for CF NBR insulation is -50℃ o +105℃ (-164℉ to +221℉).

| CF NBR Foam Rubber, Nitrile Thermal Insualtion Tube: | |||

| Characteristics: | |||

| 1. Closed-cell Structure. | |||

| 2. Low and Stable Thermal Conductivity. | |||

| 3. Low Water Absorption Rate. | |||

| 4. Good Fireproof and Soundproof Performance. | |||

| 5. Good Aging Resistance Performance. | |||

| 6. Simple and Easy Installation. | |||

| 7. Environmental friendly & Improved IAQ. | |||

| Application: | |||

| Be used to retard heat transmission and control condensation from chilled-water and refrigeration systems. It also efficiently reduces heat transfer for hot-water plumbing and liquid-heating and dual-temperature piping | |||

| It is ideal for applications in: | |||

| Ductwork | |||

| Dual temperature and low pressure steam lines | |||

| Process piping | |||

| Air-conditioner, including hot gas piping | |||

|

|||

| CF NBR FOAM Tube PARAMETER: | |||

| Physical Properties | Unit | Data | Test Methods |

| Thermal Conductivity | W/m·K (BTU·in/hr·ft2·℉) | ||

| -20℃ | 0.031 (0.225) | ASTM C518 | |

| 0℃ | 0.340 (0.240) | ||

| 40℃ | 0.380 (0.260) | ||

| Water Vapor Permeability | s·m·Pa (perm-in) | 1.16 x 10-13 (0.08) | ASTM E96 |

| Moisture Resistance | >= 7000 | ||

| Water Absorption (%) | <= 0.2 (by volume) | ||

| Flammability and smoke developed | 25/50 | ASTM E84 / ULC S102 | |

| Class 1 / Class 0 | BS 476 Part 7 | ||

| Density | Kg/m3 (lbs/ft3) | 50-90 (3.125-5.625) | ASTM D1667 |

| Mold Resistance | Good | UL181 | |

| Fungi Resistance | Good | ASTM G21 | |

| UV & Weather Resistance | Good | ASTM G23 | |

| Ozone Resistance | Good | ||

| Dimensional Stability | 0 to 7% | ASTM C534 | |

| Temperature Range | -50 – +105℃ (-164 – 221℉) | ||

We have many kinds of specifications for you to choose.

Please see the table below!

| I.D. Size | 3/8"(9mm)wall | 1/2"(13mm)wall | 3/4"(19mm)wall | 1"(25mm)wall | 1 1/4”(mm)wall | ||||||

| mm | inch | Code No. | pcs/ctn. | Code No. | pcs/ctn. | Code No. | pcs/ctn. | Code No. | pcs/ctn. | Code No | pcs/ctn. |

| 9 | 3/8" | 9009 | 130 | 13009 | 85 | 19009 | 45 | ||||

| 13 | 1/2" | 9013 | 110 | 13013 | 70 | 19013 | 40 | ||||

| 16 | 5/8" | 9016 | 90 | 13016 | 60 | 19016 | 35 | 25016 | 24 | 32016 | 20 |

| 19 | 3/4" | 9019 | 80 | 13019 | 55 | 19019 | 32 | 25019 | 22 | 32019 | 18 |

| 22 | 7/8" | 9022 | 70 | 13022 | 50 | 19022 | 30 | 25022 | 20 | 32022 | 17 |

| 25 | 1" | 9025 | 60 | 13025 | 45 | 19025 | 27 | 25025 | 18 | 32025 | 16 |

| 28 | 1 1/8" | 9028 | 55 | 13028 | 38 | 19028 | 24 | 25028 | 18 | 32028 | 15 |

| 32 | 1 1/4" | 9032 | 45 | 13032 | 35 | 19032 | 22 | 25032 | 16 | 32032 | 14 |

| 35 | 1 3/8" | 9035 | 40 | 13035 | 33 | 19035 | 20 | 25035 | 15 | 32035 | 12 |

| 38 | 1 1/2” | 9038 | 36 | 13038 | 31 | 19038 | 18 | 25038 | 13 | 32038 | 11 |

| 42 | 1 5/8" | 9042 | 35 | 13042 | 30 | 19042 | 18 | 25042 | 13 | 32042 | 11 |

| 48 | 1 7/8" | 9048 | 30 | 13048 | 24 | 19048 | 14 | 25048 | 11 | 32048 | 9 |

| 54 | 2 1/8" | 9054 | 24 | 13054 | 20 | 19054 | 12 | 25054 | 10 | 32054 | 8 |

| 57 | 2 1/4 | 9067 | 16 | 13057 | 18 | 19057 | 11 | 25057 | 10 | 32057 | 8 |

| 60 | 2 3/8" | 13060 | 16 | 19060 | 10 | 25060 | 9 | 32060 | 7 | ||

| 67 | 2 5/8" | 13067 | 12 | 19067 | 9 | 5067 | 9 | 32067 | 7 | ||

| 76 | 3” | 19076 | 8 | 25076 | 7 | 32076 | 6 | ||||

| 89 | 3 1/2" | 19089 | 6 | 25089 | 6 | 32089 | 5 | ||||

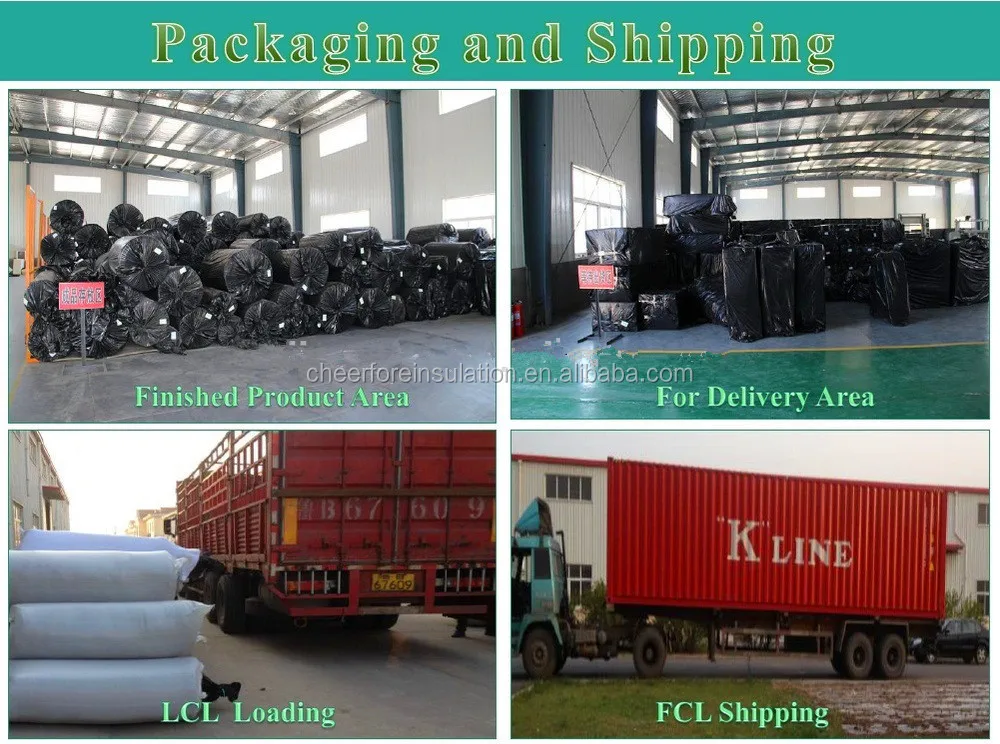

In order to ensure our heat insulation foam come to customer warehouse in good condition, we specially choose high quality exporting package like PE bag or paper carton.

Company Infomation

Guangzhou Cheerfore Insulation Co., Ltd. endeavors in R&D and innovation of thermal insulation, acoustic insulation, vibration absorption and sealing materials since its foundation in 2006.

We concentrate on thermal insulation products for power equipments and mechanical facilities, HVAC&R and construction works, etc, and acoustic and vibration insulation products for meeting room, anechoic room, industrial buildings, automobile industry, etc, and the relative accessories which to ensure the insulations work properly and efficiently.

Quality Control:

we always pay more attention to the raw material quality, standard quality control system and team are responsible to ensure the product quality in every process with different machine like extrusion equipment and mould pressing equipment.

1).The quality of our products all through the QC staff to check.

2).All of our products get through strictly quality system to control it, after four re-check before shipment, including purchasing materials, production processes, processing and packaging.

3).National Institute of Standards by SGS product certification testing.

Walmly welcome to contact us Cheerfore Insulation at anytime for any question! We will get back to you within 12 hours. Or please call us, talk on line if urgent.

Thank you for your time.