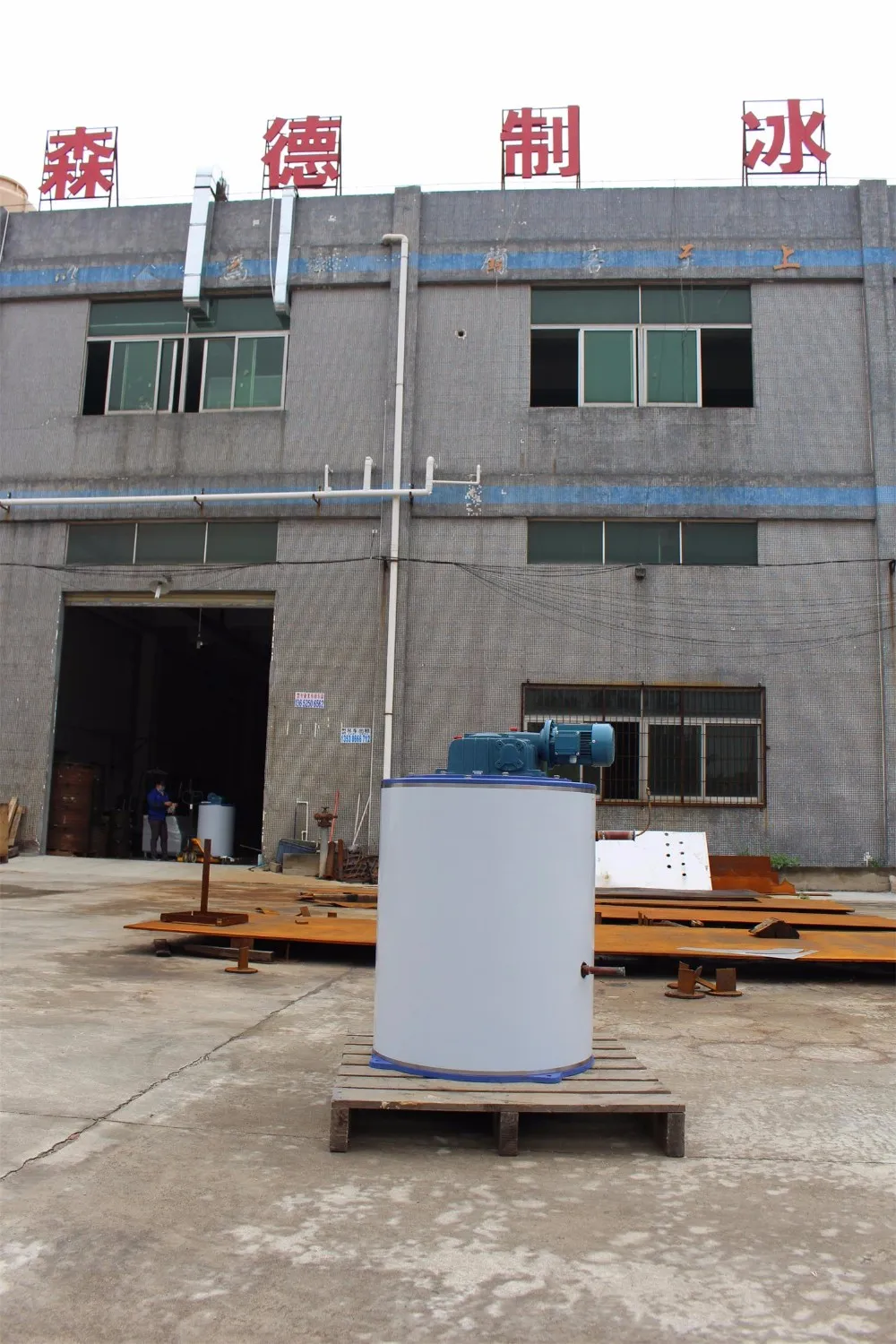

Brand Name: SINDEICE

Model Number: SDE-2T

Place of Origin: Guangdong, China (Mainland)

Sindeice Hot sale 2000kg/24h flake ice maker machine

SHENZHEN SINDEICE SYSTEMS CO., LTD (Sindeice for short) is a professional manufacturer of ice machines, who has a set of research, design, production, installation, sale and after-sales service. We got a number of experienced experts who engaged in refrigeration and ice machine for many years. With the use of best technology of ice machine and innovative solutions, Sindeice manufactures Flake ice machine, Tube ice machine, Block ice machine, Ice flaker evaporator, Containerized ice plant. Daily capacities are available from 300 kg to 100,000 kg.

Sindeice is sticking to the notion of “great virtue,social commitment”, and the management policy of “integrity, diligence, innovation and mutual benefit”.Sindeice strives to enter into international market.

Application of flake ice machine

Vegetable & Fruit preservation and transportation

In whatever development stage of mechanical refrigeration technology, it provides just cold temperature while moist environment is still void. Flake ice, with its physical characteristics, is to cool down the temperature as well as to provide sufficient water. Till now, there is no ideal replacement to supplant flake ice in this regard. So vegetables and fruits will be kept from rotting and dewatering with the presence of flake ice in the process of storage, transportation and display. Flake ice will help with long time keeping of fruit and vegetable.

Meat and Sausage Processing

In order to prevent fungi from quick propagation and to prevent the meat from getting dark and degreased because of high temperature caused in the process of sausage and ham making, a proper dose of clean and hygienic flake ice can be added to lower the temperature as this may raise the hygiene level of meat.

Sea Food Industry

Flake ice is widely used in a variety of sea food processing fields as it can provide sufficient water, and cool down the temperature in the process of melting. At whatever stage in the development history, mechanical refrigeration systems offer only cold temperature instead of moist surroundings, which is normally causing dry surface and dehydration of sea food, and reducing the freshness of sea food. While flake ice is able to provide a perfect cooling surrounding, which keeps the sea food in an ideal cold and moist status. Flake ice can prevent sea food from turning rotten and degenerate, furthermore, it may avoid cases of dewatering and dry surface. The melting ice water washes the surface of sea food, which helps reduce the content of fungi and suppress odor and reaches the ideal fresh keeping effect.

Fowl Slaughtering

In the process of bird & poultry processing, unhairing is normally done by vaporizing. High temperature may soften the poultry’s fat which is subject to rotting. So the poultry shall be cooled down immediately after unhairing to ensure the product’s freshness. Flake ice is added to the water in the screw chiller which keeps the water in a temp range of 0 –4 degrees Celsius. After cooling down in the cold water in the screw chiller, the poultry will be put in refrigerated room. Research results show that poultry treated in this way will be prevented from germ contamination.

Industries of Chemical Dye

In the composition process of biological pharmacy, chemical pharmacy and medication, a proper doze of ice is added to manipulate the temperature at which chemical reactions happen and keep the biological activation. Flake ice is hygienic and even in shape. And flowing characteristic and its sufficient unit contact area make it a most ideal temperature cooling media in chemical medication industry.

For example, in the composition process of pigments, diazotization, coupling and condensation are the three prerequisite steps. As huge amounts of heat will be released in the process of diazotization, coupling and condensation, while the ideal reaction condition is 0 – 5 degrees Celsius, plentiful flake ice will be added to manipulate the temperature so as to assure the product’s quality.

Characteristics of Flake Ice

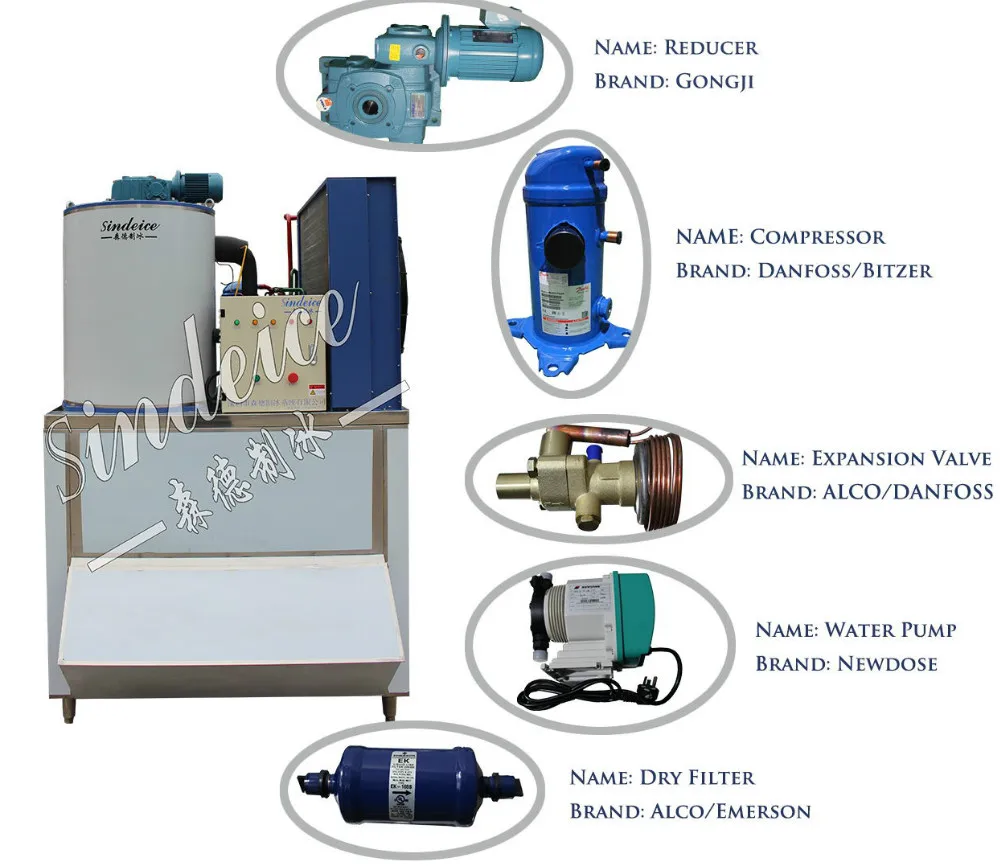

Ice Flaker Evaporator

As the key part of the complete flake ice machine, the ice flaker evaporator plays an important role in making ice. To match the various ice flaker evaporator, you can make different choice about the refrigeration units in different refrigerant (R22, R404a or R717) by yourselves. Before place the order, please let us know which refrigerant you will choose.

Characteristics

1. The ice flaker evaporator use high quality alloy material. Precision welding and surface treatment makes high heat conduction efficient, high strength, longer lifespan.

2. The internally- scraping ice-making mode has been adopted. Under this mode, ice blades scrape ice on the inner wall of the evaporator while the evaporator itself does not move. It reduces the loss of energy as much as possible, guarantees the normal supply of cooling agent as well lower the probability of cooling agent leakage.

3. The stainless steel ice scraper formed without weld. Even by long time scraping, the scrapper keeps still tough, and the ice dropped is sizable with nearly no powder.

Technical Data

*The technical data based on 25℃ ambient temp.18℃ water inlet temp.

*The evaporating temperature is -20℃.

*The condensing temperature is 40℃.

*Power supply: 3P / 380V / 50HZ 3P/220V/60HZ

*Refrigerant:R404a/R22/R507/R717

*Inner wall material: SUS304&Q345 Hard chromium plating

| Mode | SDE-2T |

| Daily Output(Ton/24hrs) | 2 |

| Neccesary Refriger(kW) | 12 |

| Voltage | 3P/380V/50Hz |

| Reductor Power(kW) | 0.37 |

| Water inlet/drain pipe | 1/2" |

| Dimension(mm) | 900*850*1030 |

| Weight(kg) | 240 |

Installation:

1). Installing by the user: we will tested and install well the machine before shipment, all necessary spare parts and operation manual are provided to guide the installation.

2). Installing by SINDEICE engineers:

(1) We can send our engineer to assist the installation and provide technical support and train your workers. The end-user provide accommodation and round-trip ticket for our engineer.

(2) Before our engineer arrived in your site, the installation place, electricity, water and installation tools should be ready. Meanwhile, we will provide you a Tool List with the machine when delivery.

Q1: What are the payment terms?

A: We usually accept payment by T/T, L/C.

Normally, we accept 30% Deposit and 70% balance paid before delivery.

Q2 : Can any of the products be custom imprinted?

A: If you need to print your company logo on the products and that is available to be custom. Or if you have your own designed idea and that will be our honor to ustomize for you.

Q3: How to ensure that I received the machine undamaged?

A: At first , our package is standard for shipping, before packing, we will confirm product undamaged, otherwise, please contact within 2days. Because we've bought insurance for you, we or shipping company will be responsible!

Q4: Do I need to install the ice machine by myself?

A: For small ice machine, we ship it as a whole unit. So you just need to prepare power and water to run the machine.

For some larger ice machine plant, we need to keep some components seperate for shipping convenience. But no worris about that. An installation brochure will be sent to you,it's very to install the machine.

Q5:What is the warranty for flake ice machine?

A: 18 months after B/L date. Any failure occurred within this period due to our responsibility, we'll supply you the spare parts for free and permanent technical support &consultation all life long for our flake ice machines.

Welcome you to visit our website,

Any questions, pls contact with us.