Brand Name: injection molding machine band heater

Model Number: DT-B072

Place of Origin: Guangdong, China (Mainland)

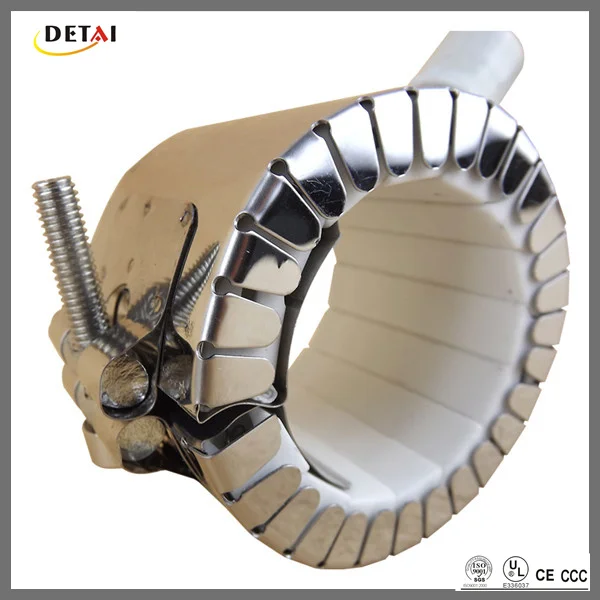

Made in China injection molding machine band heater

Introduction of injection molding machine band heater

Injection molding machine band heater is efficient, robust heaters which provide long wave infrared radiation. They are designed to heat up cylindrical parts by conduction. They are used in many manufacturing processes such as the injection, extrusion and moulding processes or other specific applications, such as tank heating and they are to be found in many industries such as the plastic processing industry, the car industry, chemical and food processing industries, etc.

Features of injection molding machine band heater

| Industrial Heater | injection molding machine band heater |

| Resistance Wire | NiCr 80/20 |

| sheath | 304 stainless steel |

| insulation | ceramic |

| Heater Voltage | 12V - 480V (other voltages available on request) |

| wavelength range | 2-10 microns |

| Operating Temperature | 300°C to 760°C (572°F - 1400°F) |

| Operating Life-Up | 20,000 hrs |

| radiation distance | 100 mm to 250 mm |

1. Stainless steel sheath

Resists rust and high temperatures, and provides firm mechanical support.

Easily wraps around barrel due to fluted construction.

2. Thermal insulation

¼ inch of ceramic fiber prevents heat loss, thereby lowering energy costs.

3. Ceramic coil supports

Designed for their dielectric and thermoconductive characteristics,

the interlocking feature provides flexibility so band wraps easily around barrel.

4. Nickel-chrome heating coil

Precision wound, helical construction gives extended service.

A heavier weight than found in mica or other conventional heaters.

Applications of injection molding machine band heater

Delivery method of injection molding machine band heater

FAQ

1. Are you manufacturer or trade company?

We are a professional factory specialized in customizing various heating element since 1995.

2. What information do you need for quotation?

Watt & volt(a must), length & diameter(optional, can be suggested by our engineers),quantity & other specific requirements.

3. How long is the lead time?

Usually 10-15 days.

4. Can you put our logo on the heater?

Yes, no problem. Please provide us with your authorization letter.

5. Can you make as per to my requirements?

Of course, all the heaters are customized.

6. How can I contact you?

Skype: Anna_heating element / Mobile: 0086-13929241568

Photo display of injection molding machine band heater