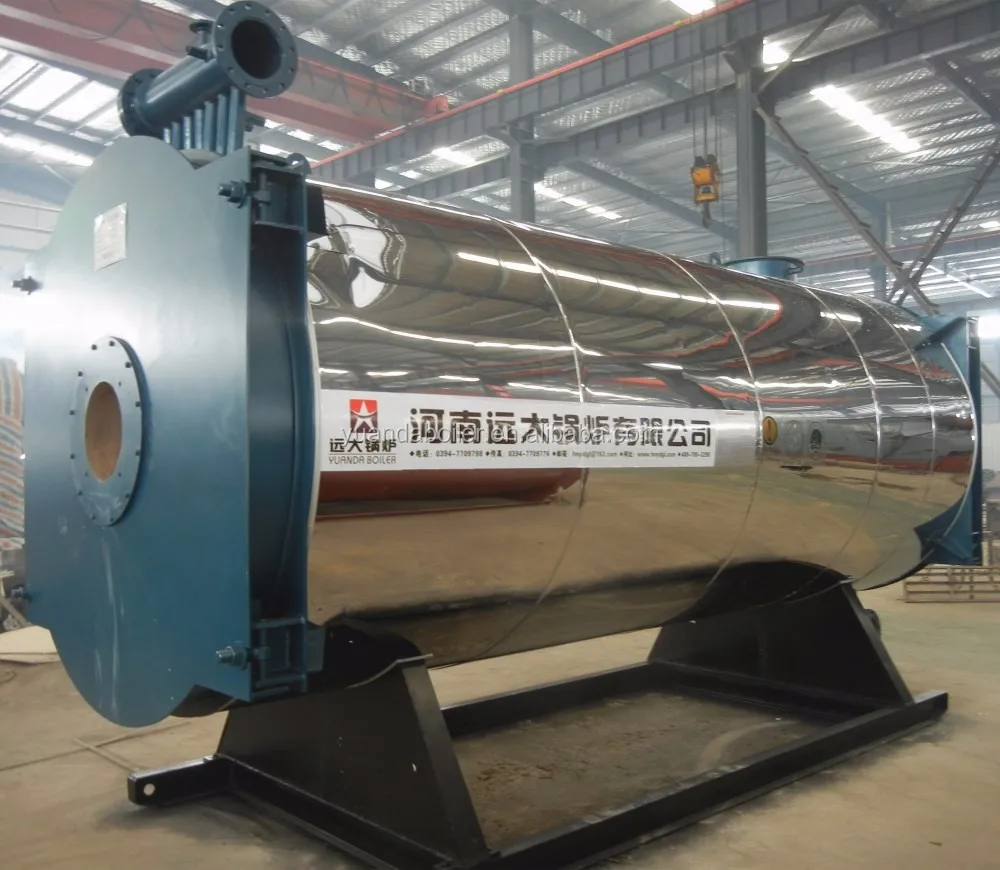

Brand Name: Yuanda Boiler

Model Number: YY(Q)W

Place of Origin: Henan, China (Mainland)

Specifications of Organic Heat Transfer Heater Boiler furnace

| Product name | YQW low pressure coil type horizontal structure gas fired thermal oil/ hot oil boilers/ furnaces/ heaters |

| Product description | Powered by circulation pumps, heating as medium, organic heat transfer oil flow out from boiler into equipments which need heat energy, transferring heat energy, and then flow back to boiler proper. The organic thermal oil flow through the whole system and transfer heating energy to heat the equipment. Gas/oil light by burner, the flame and high temperature exhausted gas flow through boiler proper and heat the system. |

| Title | Specifications of Organic Heat Transfer Heater Boiler furnace |

| Model | YY(Q)W-350, YY(Q)W-700, YY(Q)W-1400, YY(Q)W-2100, YY(Q)W-2900, YY(Q)W-4500 |

| Rated thermal power | 350kW, 500kW, 700kW, 1400kW, 2100kW, 2900kW, 4500kW |

| Rated working pressure | 8Bar |

| Max. working temperature | 320°c |

| Design fuels | Natural Gas, LPG (Liquefied Petroleum Gas, Liquid Propane Gas), LNG (Liquefied Natural Gas), CNG (Compressed Natural Gas), city gas, coal gas, biogas, waste gas, etc. |

| Features | 1.Low pressure but high temperature, safe, high efficiency and saving energy. 2.Thermal fluid oil runs in the whole working system, without contacting with airs, no emissions, no pollution, less heat loss, long working life, saving fuels and low running cost. 3.It can meet the requirement of different machines which needs various temperature in different processing manufacture. |

| Appllication | 1.Chemical Industry --polymerization industry, oil industry, reaction tank, distillation, enrichment 2.Plastic industry ---plastic and squeeze to finalize the design 3.Textile industry -- resin stenters, dyeing machine and the dry room, high temperature machine, roller. 4. Rubber industry - rubber vulcanization heating 5. Food industry -- cooking dry, vegetable oil refining 6. Wood industry -- heating to finalize the design of chipboard sandwich plate, warm up board, fiber 7. Paper industry-multi-layer cardboard of packed carton box, dying and desiccation 8. Others-heating of metal electroplating slot, coating condensation, drying, distillation of pharmaceutical industry, reduction, concentration, dehydration, airconditioning industry, etc. |

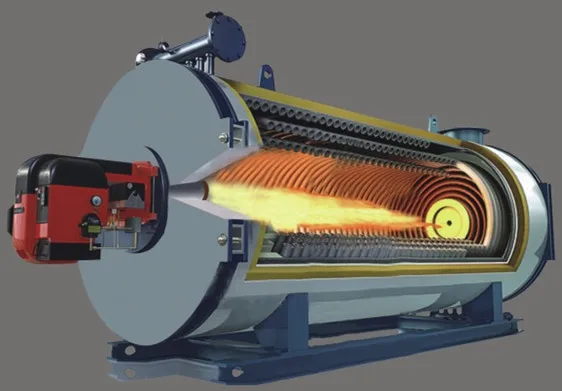

The inner structures of YQW low pressure coil type horizontal structure gas fired thermal oil/ hot oil boilers/ furnaces/ heaters are as follows,

The working system of YQW low pressure coil type horizontal structure gas fired thermal oil/ hot oil boilers/ furnaces/ heaters is as follows,

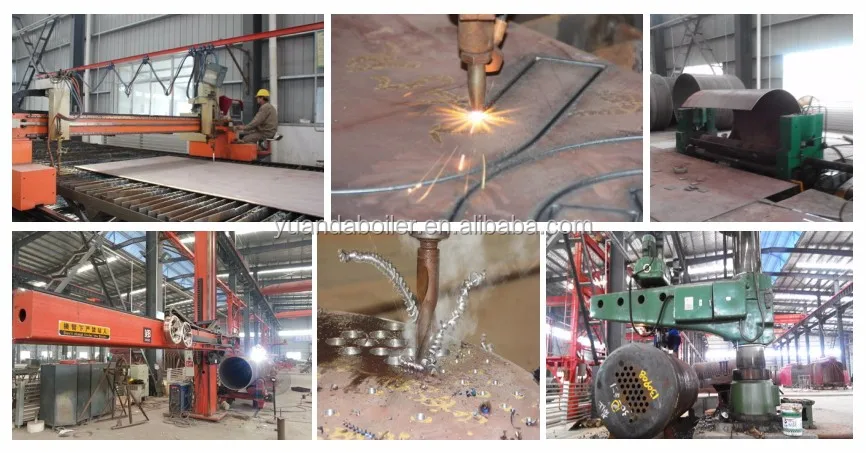

Yuanda Boiler committed to meet customer requirements and satisfaction through delivery of highest quality and reliable products and services in cost effective manner. Our Company adheres to the guideline of good reputation, good service, high quality, low prices and continuous improvement. We create first-rate products with innovation and excellence and have extensive quality control procedures. We believe in meeting the requirements of customers, abiding by the laws & regulations and improve quality management system consistently. Our company puts our heart and soul into serving the customers with high quality products, competitive price and excellent after sales services.

Henan Yuanda Boiler Co., Ltd. was established in 1956. We are professional manufacturer and supplier of industrial boilers, with fifty years' experience in boiler design, technique, production, installation and operation. Our company is one of the leading enterprises which first obtained the national boiler manufacturing license in China.Our plant locates in Zhoukou city and office in Zhengzhou city, Henan province, the central part of China. Yuanda Boiler already passed and got the ISO 9001 Quailty Management System Authentication Certificate, which regulate the whole working process of factory.

The quality policy of Yuanda focuses at achieving the highest standards in terms of quality of work, which will consistently satisfy the customers and exceed their expectations, thereby providing a sustainable, profitable growth to the company. We follow a definite, contrived process in all our services to accomplish the undertaking at the best of quality, time and cost to benefit our customers and the company as a whole. This in turn reflects the competence of the company to the customers and prospective market.

The responsibility of ensuring and following the company quality policy rests on the shoulder of each and every employee of Yuanda, and each individual employee is accountable to himself. This perennial effort to ensure safety, quality and customer satisfaction has put Yuanda on the forefront of boiler industry in a short period of time and will always strive to do so in future.