Brand Name: Yuanda Boiler

Model Number: DZL

Place of Origin: Henan, China (Mainland)

can burn sugarcane or bagasse fuel / pellets steam boiler for sugar industries machinery

| DZL industrial low pressure single drum horizontal automatic chain grate stoker coal/ biomass fuel/ biomass pellets/ wood/ wood pellets fired steam boilers | |

| Title |

can burn sugarcane or bagasse fuel / pellets steam boiler for sugar industries machinery |

| Structure |

horizontal, single drum, three pass heating |

| Rated steam capacity | 1ton/h, 2ton/h, 4ton/h, 6ton/h, 8ton/h,10ton/h |

| Rated working pressure | 7bar, 10bar, 13bar, 16bar, 25bar |

| Rated saturation steam temperature | 171°c, 184°c, 194°c, 204°c, 226°c |

| Design fuels | coal, biomass fuel, wood, pellets, biomass pellets, wood pellets, rice husk, wood chips, bagasse, wood briquets, biomass briquets, straw pellets, walnuts shells, peanuts shell, etc. |

| Warranty | one year |

| Boiler features | 1.Single drum, horizontal, automatic chain grate stoker 2.Boiler furnace, side arches, spirally corrugated tubes form three pass heating. 3.Automatic electrical cabinet control, the whole system of coal feeding, chain grate regulator, water supply, slag remover, fresh air and exhausted gas in and out runs automatically. |

| Applications | Provide steam and energy to following industries, 1.Food industry 2.Beer, wine and beverage industry 3.Textile and leather industry 4.Plastic and rubber industry 5.Chemicals industry 6.Medicines and pharmaceuticals industry 7.Metal and metallurgy industry 8.Energy & mineral industry 9.Other related industries |

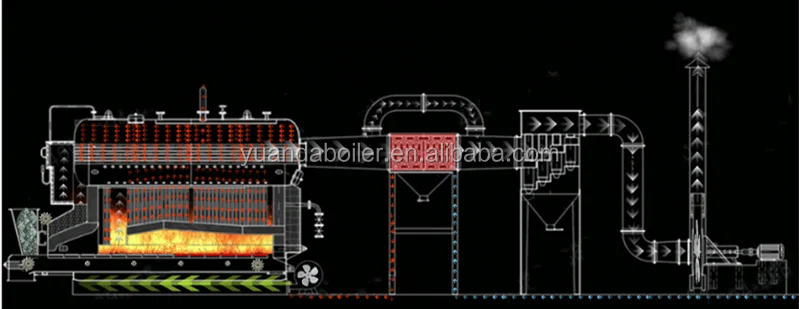

The working process of DZL industrial low pressure single drum horizontal automatic chain grate stoker coal/ biomass fuel/ biomass pellets/ wood/ wood pellets fired steam boilers is as follows,

1.Automatic fuel feeder feeds fuels into hopper, then grate speed regulator drive chain grate and fuels moving forwarder with a reasonable speed.

2.Feed water flow through economizer and automatic water softener, after treatment, drived by water pump, into boiler proper by down pipes.

3.Forced draught fan will blow fresh air into boiler furnace. Then drived by induced draught fan, the high temperature exhausted gas flow through back part of furnace into side archs to the front smoke chamber, through spirally corrugated tubes into back smoke chamber into economizer to be cooled by feed water.

4.Water in boiler are heated in drums and pipes is evaporated into steam, flow out from steam outlet in the top of boiler drum, then through steam pipes into steam header. The steam from steam header can flow to several steam pipes in different directions as required.

5.The exhausted gas flow out from economizer into dust collectors to remove dusts and then out of chimney.

6.The slag are moved into the back part of chain grate, drop into the slag extractor, and carried out of boiler.

7.During the whole process, valves and gauges send detection pressure figure, steam temperture and other signals to electrical cabinet, ensure the whole working system running automatically and safely.

8. can burn sugarcane or bagasse fuel / pellets steam boiler for sugar industries machinery

Coal & Biomass fuels

Standard supply scope of DZL industrial low pressure single drum horizontal automatic chain grate stoker coal/ biomass fuel/ biomass pellets/ wood/ wood pellets fired steam boilers are as follows,

| Boiler main part | 1 set |

| Blower | 1 set |

| Induced draft fan | 1 set |

| Valves & meters | 1 set |

| Governor box | 1 set |

| Electrical cabinet | 1 set |

| Fuel feed equipment | 1 set |

| Water supply pumps | 2 sets |

| Water treatment equipment | 1 set |

| Slag extractor | 1 set |

| Economizer | 1 set |

| Dust collector | 1 set |

| Gas flue | 1 set |

| Chimney | 1 set |

| Steam header | 1 set |

Pictures of customer's installation site

Descriptions and Functions of Auxiliary Machines

| Descriptions | Functions |

| Forced draught fan | Blow clean air into boiler and promote exhauted gas out, ensure the air circulation of the whole system. |

| Induced draught fan | |

| Feed water pump |

Put water into boiler working system. |

| Automatic water softener | Remove Mg+ Ca+ in the water and improve water quality. This is good for boiler proper and tubes, prolong the service time. |

| Electrical cabinet | Be responsible for electrical control of auxiliary machines, ensure the whole system working automatically and make the operation convenient. |

| Grate speed adjustor | Regulate the suitable speed of chian grate according to the combustion situation. |

| Slag remover | Extract slags mechanically and save labour cost. |

| Economizer | Heat inlet water and reduce exhausted gas temperature, which increase boiler efficiency and is good for environment |

| Dust collector | Remove the dust and ash in exhausted gas to protect envrionment and reduce polutions. |

| Gas flue and Chimney | Provide channels for exhausted gas flow. |

| Steam header |

Distribute steam to different directions |

| Safety Valves | It will work automatically when the working pressure is over high to protect the whole system |

| Pressure Gauge | Show the working pressure of the boiler |

| Check Valves | Connect pipes to ensure water not to flow backwards |

| Blow-down Valves | To let out the sediment, impurities or other things in the bottom |

| Shut-off Valves | Turn on or off the pipes |

| keywords | can burn sugarcane or bagasse fuel / pellets steam boiler for sugar industries machinery |