Brand Name: BZ

Model Number: WNS/YQW

Place of Origin: Hebei, China (Mainland)

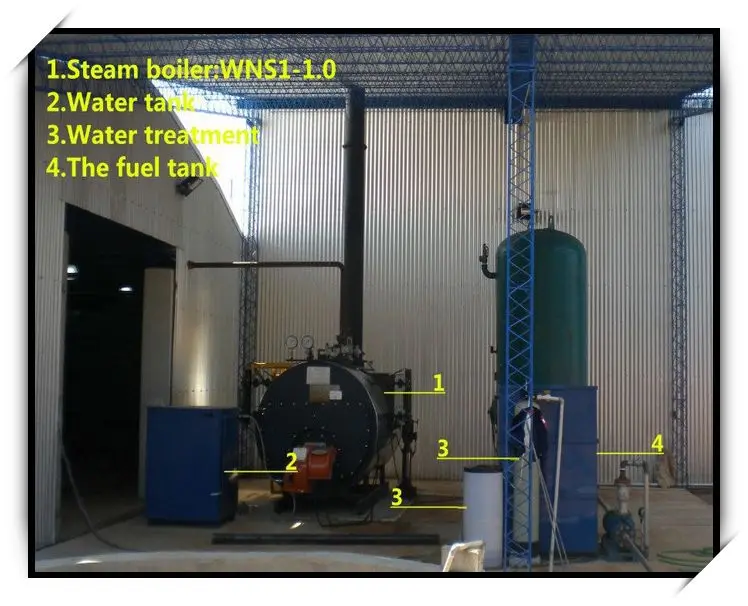

WNS type gas boiler gas fired water steam thermal oil boiler gas boiler

General features of WNS series steam boiler:

1. horizontal , gas & oil fired , water tube, industrial and low pressure;

2. wetback and three-backhaulstructure design;

3. With high efficiency economizer, the thermal efficiency can reach more than 90%.

4. The spring-loaded type explosion door ensures the boiler safety

5. The removable smoke boxfacilitates the maintenance

6. Internal micro positive pressure combustionreduces the low temperature corrosion.

7. Equipped with protection devicesfor overheating, overpressure, lacking water, leak detection, flameout, etc. This ensures the boiler to operate safely and efficiently.

The product advantage:

1. Subulate furnace and corrugated furnace combination

Function: (1) Make the structure more compact; (2) improve the thermal efficiency; (3) relieve the expansion and contraction

2. Smooth tube and spirally corrugated tube combination

The smooth tube

Function: Prevent the exhaust from condensing inside the boiler to prolong its service life ;

The spirally corrugated tube

Function: (1) relieve the expansion and contraction; (2) Heat transfer enhancement;; (3) clean groove by itself.

3. The furnace sits in line with the combustion

Function: (1) Make the structure more compact; (2) prolong its service life;

Mark:

The combination of our gas fired boiler, imported burner and economizer are the perfect match, which is high-efficient, environment-friendly and energy-saving.

The measures of quality assurance as follow:

1. Strength calculation report with applied materials information;

2. 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

3. 100% X-ray inspection report (welding seam): to ensure the quality of the entire boiler;

4. Hydraulic test report: ensure the standard working pressure and safety;

| Projects | unit | WNS1 | WNS2 | WNS4 | WNS6 | WNS10 | WNS15 | WNS20 | |

| rated evaporation | t/h | 1 | 2 | 4 | 6 | 10 | 15 | 20 | |

| Nominal steam pressure | Mpa | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | |

| Nominal steam temperature | °c | 194 | |||||||

| Rated inlet water temperature | °c | 20 | |||||||

| body heating surface | m² | 25.5 | 60 | 111 | 160 | 260 | 380 | 482 | |

| Economizer heating surface | m² | 5 | 10 | 16 | 25 | 30 | 46 | 62 | |

| Design thermal efficiency | % | 91.8 | |||||||

| Design environment temprature | °c | 20 | |||||||

| Design blowdown rate | % | 4 | |||||||

| Net weight of boiler | t | 6.5 | 9.8 | 14.8 | 20.7 | 30.4 | 43.3 | 50.4 | |

| operational water volume | t | 3 | 5 | 7.5 | 10.7 | 16.7 | 25 | 31.5 | |

| full water volume | t | 4 | 6.8 | 10 | 14.6 | 22.3 | 31.1 | 36.6 | |

| Fuel consumption | Natural gas | Nm3/h | 75.4 | 149 | 298 | 447 | 743.6 | 1084.4 | 1444.3 |

| Diesel | kg/h | 64 | 132 | 265 | 382 | 636 | 951 | 1267.6 |

|

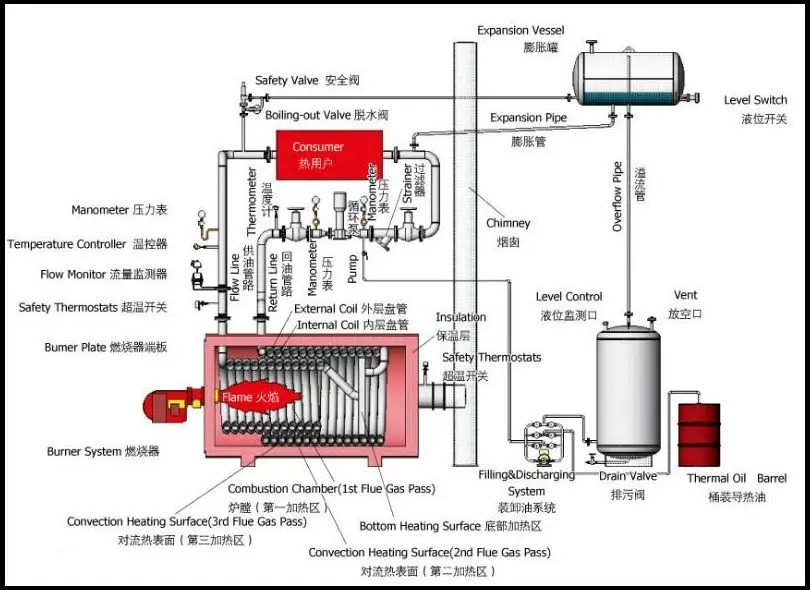

Brief introduction

YQW series thermal oil boiler is a kind of horizontal type forced circulation organic heat carrier boiler. It takes diesel, gas, town gas and oil as fuel and takes closely-arranged coils as heating surface including radiant heating surface and convection heating surface. For large-capacity boiler, the ceiling coils are equipped to ensure the compact structure.

The flue gas goes in three pass and heat recovery boiler or air-preheater can be allocated to save energy and improve its thermal efficiency well. New-type insulation method is taken to reduces the thermal loss.

Features:

1. Its heating surface is made up of closely-arranged coils;

2. The boiler can take diesel, gas, town gas and oil as fuel;

3. Adopts automatic computer control to achieve DCS control and remote control;

4. The burner and thermal load can be adjustable automatically.

5. This boiler can be widely used in textile, chemical, wood, oil, rubber, plastics, food, paper, pharmaceutical, reduction, concentration, dehydration, forest product industry…etc.

Technical parameters

| Projects | units | YQW-700Q | YQW-1000Q | YQW-1400Q | YQW-2000Q | YQW-2400Q | YQW-2900Q | YQW-3500Q | YQW-4700Q | YQW-6000Q | YQW-7000Q | YQW-10000Q | YQW-12000Q | YQW-14000 |

| Thermal power rating | kw | 700 | 100 | 1400 | 2000 | 2400 | 2900 | 3500 | 4700 | 6000 | 7000 | 10000 | 12000 | 14000 |

| Design pressure | mpa | 1.3 | 1.3 | 1.3 | 1.3 | 1.3 | 1.3 | 1.3 | 1.3 | 1.3 | 1.3 | 1.3 | 1.3 | 1.3 |

| highest medium pressure | °c | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 |

| inner medium capacity | m3 | 0.51 | 0.6 | 0.94 | 1.54 | 1.9 | 2.37 | 3.54 | 4.34 | 6.46 | 7.83 | 12.5 | 14 | 15 |

| cycle volume of medium | m3/h | 40 | 60 | 80 | 160 | 160 | 180 | 200 | 250 | 350 | 350 | 400 | 500 | 600 |

| pipe connection diameter | mm | 80 | 125 | 125 | 150 | 150 | 150 | 200 | 200 | 250 | 250 | 300 | 350 | 350 |

| thermal efficiency | % | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| heating surface area | m² | 39.84 | 50.5 | 72.29 | 91.67 | 115.68 | 138.65 | 163.21 | 206.84 | 249.71 | 300.73 | 395 | 480 | 570 |

| weight | t | 5.5 | 7 | 9.8 | 12.7 | 14.6 | 17.5 | 23.2 | 27 | 33.6 | 40 | 48.5 | 60 | 86 |

| transport size | length (mm) | 3793 | 4044 | 4724 | 5187 | 5870 | 6115 | 6766 | 7695 | 8424 | 9096 | 10000 | 11500 | 14100 |

| width (mm) | 1830 | 1956 | 2161 | 2449 | 2560 | 2664 | 3058 | 3135 | 3405 | 3631 | 4010 | 4180 | 4250 | |

| height (mm) | 1915 | 2007 | 2217 | 2428 | 2506 | 2707 | 3018 | 3088 | 3388 | 3593 | 4100 | 4250 | 4300 |