Brand Name: Bangzi

Model Number: WNS

Place of Origin: Hebei, China (Mainland)

1000 to 10000 kg/hr steam capacity oil fired steam boiler, oil steam boiler, oil boiler

1.Fuel diesel fired steam boiler

2.3 pass fire tube corrugated furnace,enlarge heating area,steady output

3.PLC Control system,make the boiler operate full automatically,labor saving

4.High efficiency,can arrive 94% and higher

5.Package boiler,easy to install and transport

6.Widely used in food factory,chemical factory,dyeing factory,paper factory,textile factory,feed mill

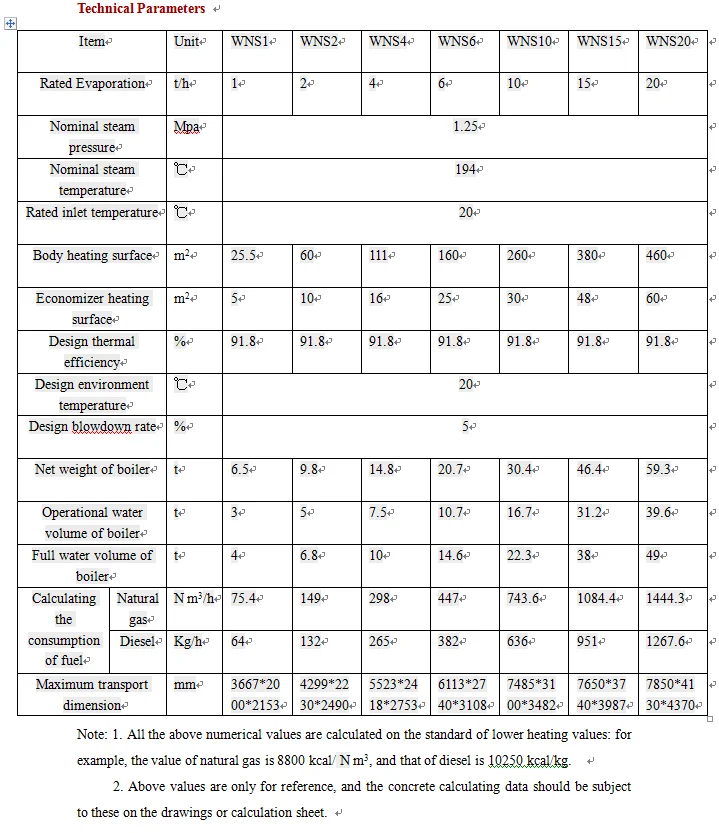

Light diesel oil fired steam boiler specifications

General features of WNS series steam boiler

The product advantage:

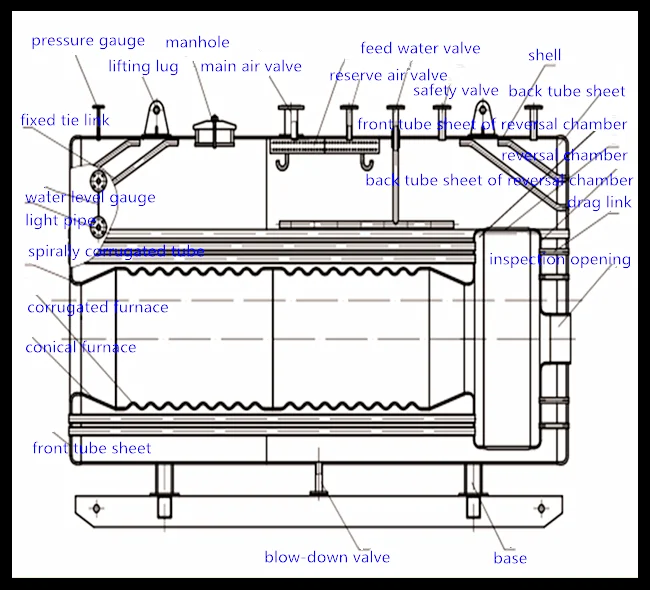

1. Subulate furnace and corrugated furnace combination

Function: (1) Make the structure more compact; (2) improve the thermal efficiency; (3) relieve the expansion and contraction

2. Smooth tube and spirally corrugated tube combination

The smooth tube

Function: Prevent the exhaust from condensing inside the boiler to prolong its service life ;

The spirally corrugated tube

Function: (1) relieve the expansion and contraction; (2) Heat transfer enhancement;; (3) clean groove by itself.

3. The furnace sits in line with the combustion

Function: (1) Make the structure more compact; (2) prolong its service life;

Mark:

The combination of our gas fired boiler, imported burner and economizer are the perfect match, which is high-efficient, environment-friendly and energy-saving.

Fire tube Diesel fired Steam Boiler structure

Best China industrial fuel oil and gas steam boiler manufacturers:

1. horizontal , gas & oil fired , water tube, industrial and low pressure;

2. wetback and three-backhaulstructure design;

3. With high efficiency economizer, the thermal efficiency can reach more than 90%.

4. The spring-loaded type explosion door ensures the boiler safety

5. The removable smoke boxfacilitates the maintenance

6. Internal micro positive pressure combustionreduces the low temperature corrosion.

7. Equipped with protection devicesfor overheating, overpressure, lacking water, leak detection, flameout, etc. This ensures the boiler to operate safely and efficiently.

Boiler spare Parts

Warranty:

One-year warranty and full-life service for all of our steam boilers

Boiler spare parts service:

A full range of original spare parts are available for all Yuanda boilers

Service before sale:

Provide relative technical data for customer choosing equipments,layout drawing,foundation,general grawing.

Service after sale:

Help customer for installation and traing.

Maintenance and repair for one year.

The measures of quality assurance as follow:

1. Strength calculation report with applied materials information;

2. 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

3. 100% X-ray inspection report (welding seam): to ensure the quality of the entire boiler;

4. Hydraulic test report: ensure the standard working pressure and safety;