|

Application Features |

|

• Molybdenum wire is refers to the line cutting with a high-voltage electric field to move continuously to cut the workpiece by a molybdenum and other precious metals made of consumables, that WEDM workpiece when moving continuously fine metal wire called the electrode wire Called the electrode), which can be carried out on the workpiece pulse spark erosion erosion, cutting metal forming. Molybdenum wire according to the different materials there are many other uses are as follows: •1. Pure molybdenum wire is used for wire around the wire, stents, leads, heating elements, molybdenum foil tape, wire molybdenum wire applications - fast wire cutting machine tools, auto parts, such as spraying. •2. Lanthanum molybdenum wire is used for winding wire glass sealing parts, molybdenum foil tape, furnace heating materials, wire cutting high temperature components. •3. Yttrium molybdenum wire is used for the bracket, lead wire, tube reed, gate, furnace heating materials, high temperature components. •4. Wire cutting molybdenum wire is used for cutting a variety of non-ferrous metals, iron and steel and magnetic materials. That with the high strength, good discharge performance, high surface finish, cutting speed, long life and other characteristics. |

Product Description |

|

Term |

Molybdenum wire |

Grade |

Mo1,Mo2 |

Size |

as request |

Surface condition |

hot rolling, cleaning, polished |

MOQ |

1 kilograms |

Test and Quality |

dimension inspection |

appearance quality test |

|

process performance test |

|

mechanical properities test |

|

Manufacturing process |

Metal molybdenum powder - compression molding - sintering - metal molybdenum bar, rod - rolling, rotary forging billet - butt welding, grinding - spin forging stringing- tensile testing - finished molybdenum wire |

Payment |

L/C, D/A, D/P, T/T, Western union, MoneyGram, Paypal, Wire-transfer |

Delivery time |

10-15 working days |

The specification would be changed by the customers' requirements. |

|

General & Dimension

| Diameter(mm) | Dia Tolerance(%) | Weight(200mm) ,mg | Lenght(min) m |

|

0.15-0.03 |

/ | 0.360-1.440 | 2000 |

| 0.03-0.1 | 1.440-16 | 1500 | |

| 0.1-0.2 | ±0.5-±1.5 | 16-256 | 1000 |

| 0.2-0.4 | 300 | ||

| 0.4-0.7 | ±1.5-±2.5 | / | 200g |

| 0.7-1.8 | ±1.0-±2.0 | 250g |

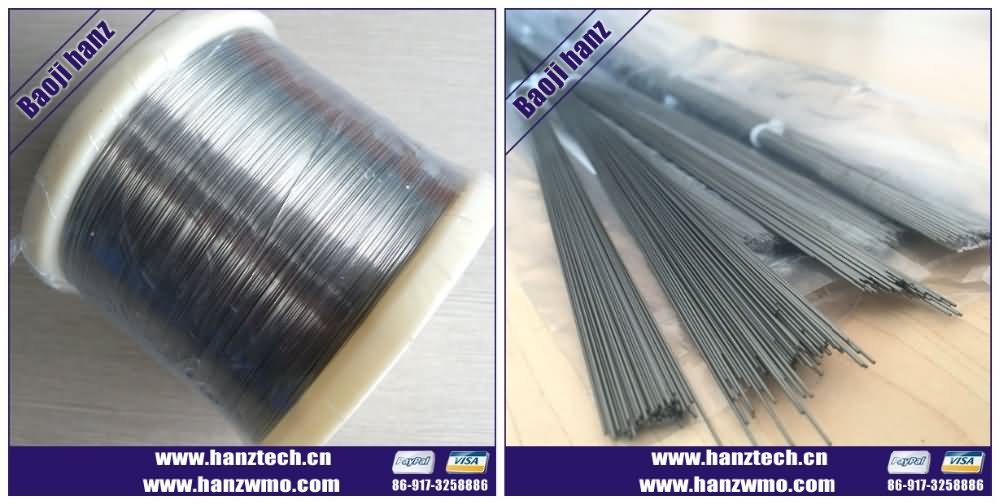

Product shows

Advantagesof high quality TZM molybdenum alloy sheet/plat

•1, good corrosion resistance (The surface of molybdenum rod is easy to produce a layer of dense natural protective film, It can be well to protect the matrix from corrosion by artificial anodic oxidation and coloring, good casting performance can be cast aluminum alloy or processing Plastic deformation of good aluminum alloy.)

•2, high strength (molybdenum rod have the high strength.After a certain degree of cold processing can strengthen the matrix strength, some grades of molybdenum rod can also be enhanced by heat treatment)

•3, good thermal conductivity (The conductive thermal conductivity of molybdenum only less than the silver, copper and gold)

•4, easy processing (After add some certain alloying elements, you can get a good casting performance of aluminum alloy casting or processing plastic deformation of aluminum alloy)

f high quality TZM molybdenum alloy sheet/plat

Packaging of high quality TZM molybdenum alloy sheet/plate

• Carton with water proof paper and protective foam inside

• Standard wooden case

• As consumers' requirements

Shipping of high quality TZM molybdenum alloy sheet/plate

• Transport: TNT, EMS, UPS, FED, DHL, Air transport, Sea Transport, Railway Transport.

• Consumers' request for shipment is available.

• We will recommend the most appropriate transport way for reference.

1. Sample order: western-union, Paypal, Escrow and T/T100% are accepted.

2. Big order: T/T100%, full payment advanced, L/C are accepted.

We accepted all payment terms ( like western union, money gram, paypal, escrow etc. ).

Please choose which terms is convenient for you. Depends on your order, we also will recommend the most suitable way.

• Your inquiry will be answered at earliest time

• Direct manufacturer

• Pre-sales ( online consultation )

• After-sales ( timely delivery )

• Design R&D center

• QC for each product

------------------------------------------------------------------------------------------------------------------------------------------

Baoji Hanz Material Technology Co., Ltd.

Sales: Lawrence Tian

China Tel: +86-917-3258886

ChinaFax: +86-917-3258889

China Mobile(WhatsApp): +86 18992714892

Email:hztech01@hanztech

your SUCCESS is our business

feel free to send us your inquiry